Magnesia fly ash cement composition, and product and manufacturing method thereof

A technology of fly ash cement and its composition, which is applied in the field of building materials engineering, can solve the problems of not being suitable for dismantling-free formwork, prone to alkali-aggregate reaction, etc., and achieve the effect of improving construction efficiency and increasing use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, making 20mm thick prefabricated building free from demolition laminated floor slab bottom slab

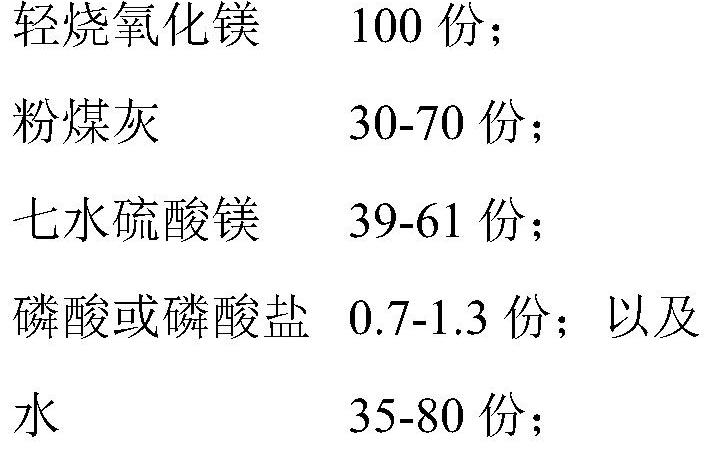

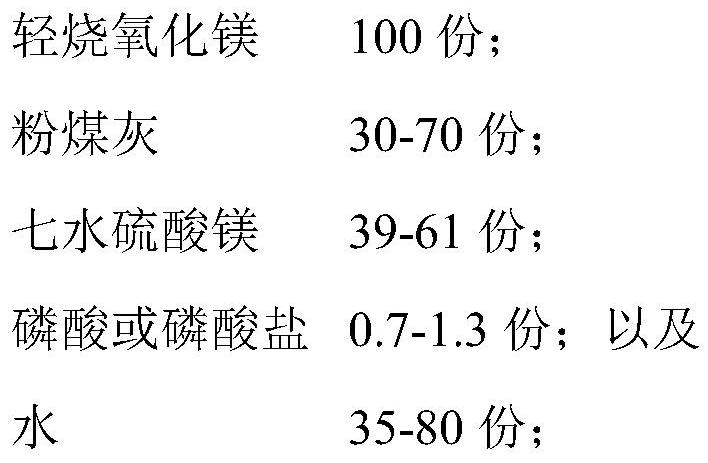

[0037] Al in the chemical composition detected after pre-homogenization of imported fly ash 2 o 3 26%, SiO 2 It is 48%, according to the proportioning ratio of each component material of the preferred magnesia fly ash cement of test is: 100 parts of light-burned magnesia, 50 parts of fly ash, 52 parts of magnesium sulfate heptahydrate, 0.7 part of phosphoric acid, 58 parts of water. According to the production process steps in the content of the invention, it is stirred into a magnesia fly ash cement slurry; after the slurry is made, 15 parts of wood chips are added and stirred into a slurry. The upper and lower layers of 200g per square meter of glass fiber mesh cloth are rolled into slabs, and they are cured in a curing room at 35 degrees Celsius for 8 hours to release the mold. After 15 days of natural curing, all performance indicators can reach JC / T412....

Embodiment 2

[0038] Embodiment 2, making 8mm thick frame type building production workshop without dismantling cast-in-place cement exterior wall formwork

[0039] Al in the chemical composition detected after pre-homogenization of imported fly ash 2 o 3 18%, SiO 2 According to the ratio of each component material of the preferred magnesia fly ash cement according to the test, it is by weight: 100 parts of light-burned magnesia, 58 parts of fly ash, 41 parts of magnesium sulfate heptahydrate, potassium dihydrogen phosphate 1.3 parts, 37 parts of water. According to the production process in the content of the invention, the magnesia fly ash cement clean slurry is stirred; after the clean slurry is made, it is mixed with 7 parts of modified vinylon fibers to form a magnesia fly ash cement semi-dry slurry. Cut off after being paved and formed, and stacked one by one on the stacker. After stacking to a certain height, apply a pressure of 5 MPa in a plane press, lock the mold clamping devic...

Embodiment 3

[0040] Example 3 Making hollow slats for partition walls in prefabricated buildings

[0041] Al in the chemical composition detected after pre-homogenization of imported fly ash 2 o 3 33%, SiO 2According to the ratio of each component material of the preferred magnesia fly ash cement according to the test, it is by weight: 100 parts of light-burned magnesia, 43 parts of fly ash, 56 parts of magnesium sulfate heptahydrate, sodium hexametaphosphate 1.0 parts, 63 parts of water. According to the production process steps in the content of the invention, it is stirred into a clean slurry of magnesia fly ash cement; after the clean slurry is made, add 30 parts of wood chips and 10 parts of chopped palm fiber, stir it into a slurry, and pour hollow strips into the hollow strips by group forming method After 3 hours of normal-pressure steam curing with molds, and 14 days of natural curing after demoulding, all performance indicators can meet the technical requirements specified in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com