Hot-pressing sintering process for improving density of ceramic material

A hot-pressing sintering and ceramic material technology, applied in the field of ceramic manufacturing, can solve the problems of low efficiency, low efficiency, and the shape change of ceramic parts, and achieve the effects of improving smoothness and uniformity, increasing specific surface area, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

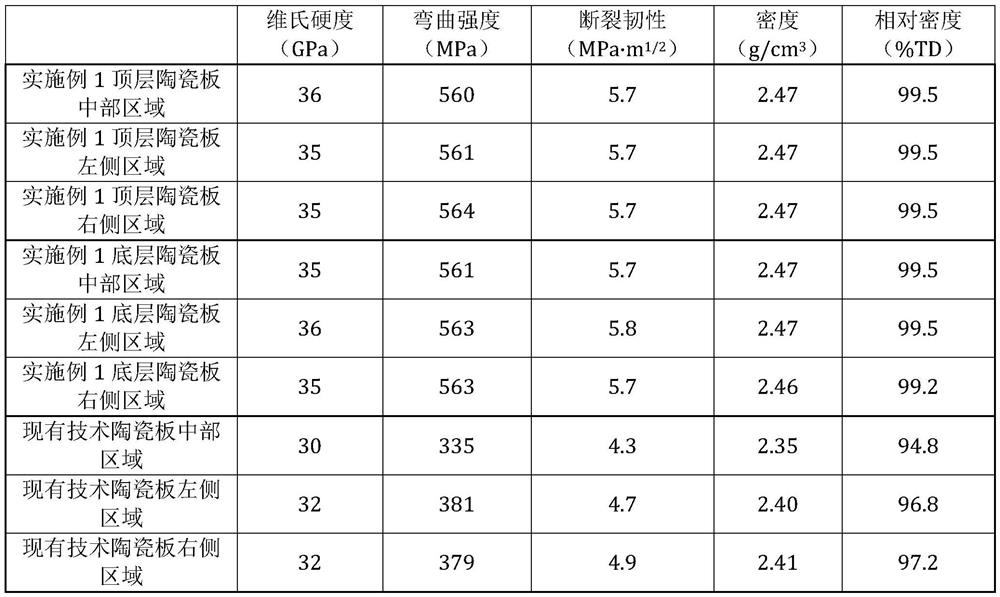

Examples

Embodiment 1

[0025] This embodiment relates to a hot pressing sintering process for increasing the density of bulletproof ceramic materials.

[0026] The green body is prepared before hot pressing and sintering, including the following processes:

[0027] 20kg of B 4 C powder (Saifu Nanotechnology), 2kg of nano-carbon fiber (Suzhou First Element CNTcr), 580g of water-soluble phenolic resin and 23kg of high-purity water are evenly mixed to obtain a ceramic slurry; then spray-dried, spray-dried air inlet temperature at 200°C, and the air outlet temperature at 100°C, the composite raw meal is obtained; finally, it is cold-pressed under a pressure of 350MPa into such figure 1 Shown, a ceramic green body 6 with a thickness of 20 mm.

[0028] The hot pressing sintering process includes the following steps:

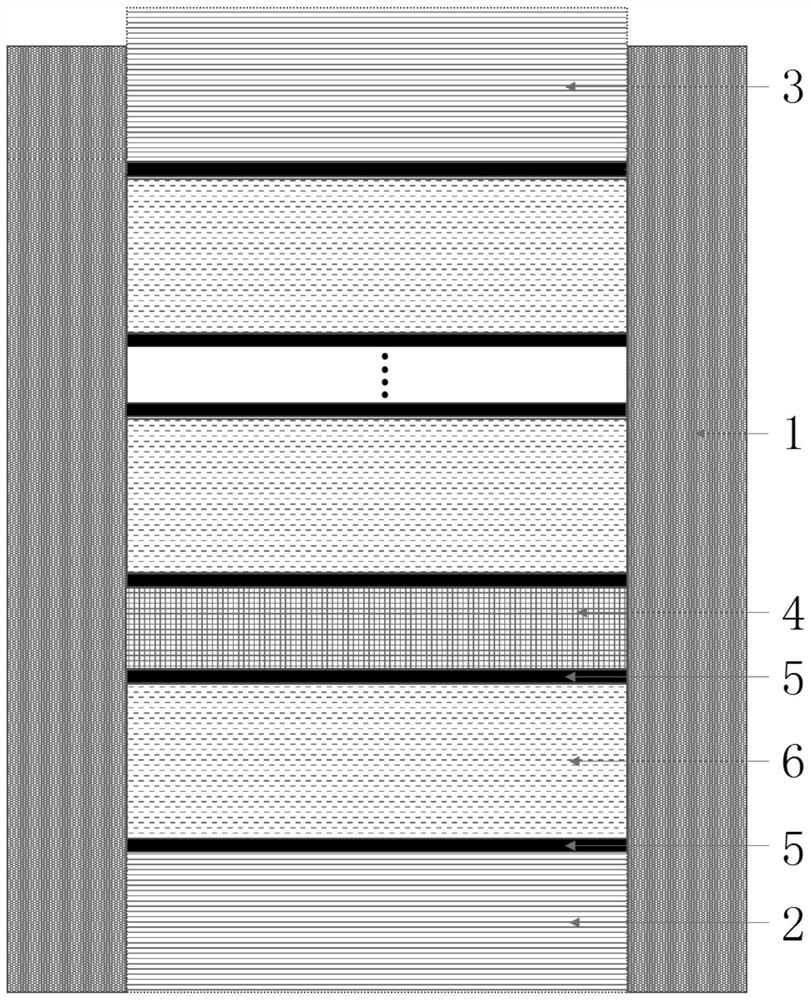

[0029] S1, using a graphite sleeve mold 1 whose inner cavity matches the shape of the ceramic green body, put the corresponding high-strength graphite lower briquetting block 2 into the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com