Insect-resistant polymethyl methacrylate and preparation method thereof

A technology of polymethyl methacrylate and methyl methacrylate, which is applied in the field of insect-proof polymethyl methacrylate and its preparation, can solve the problems of poor scratch resistance, low application value, and small application range, etc. Achieve the effect of simple process, good quality and good economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

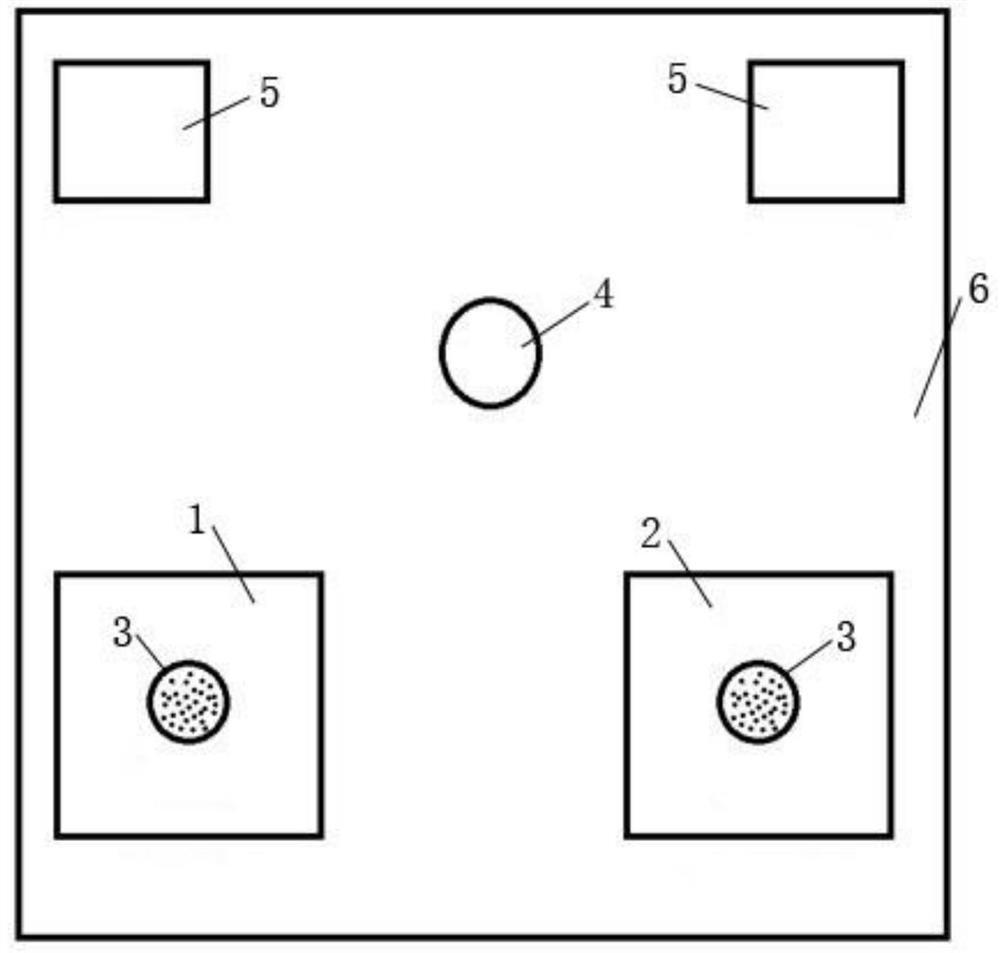

Image

Examples

preparation example Construction

[0024] Concrete, the preparation method of insect-proof polymethyl methacrylate material described in the application comprises the following steps:

[0025] 1) Mix 9-11 parts of methyl methacrylate and 0.005-0.015 parts of initiator uniformly at a temperature not exceeding 40°C, and after fully dissolving, add them to the reaction kettle and heat the reaction to obtain a reaction liquid; wherein, the reaction temperature is set to 85°C-95°C, the sign of the end of the reaction is: when the viscosity of the reaction liquid at 25°C is greater than or equal to 1000Pa·S, stop heating and allow the reaction liquid to cool naturally. This step is a pre-polymerization process used to control the polymerization process of polymethyl methacrylate. During the reaction, in order to better control the degree of polymerization, we should pay close attention to its viscosity change after the reaction is carried out for 5-10 minutes, so as to Appropriate frequency to test its viscosity at 2...

Embodiment 1

[0034] The application provides an insect-proof polymethyl methacrylate and a preparation method thereof, the preparation method comprising the steps of:

[0035] 1) Mix 9-11 parts of methyl methacrylate and 0.005-0.015 parts of azobisisobutyronitrile initiator uniformly at a temperature not exceeding 40°C, fully dissolve them, put them into a reaction kettle and heat to react to obtain a reaction liquid; Among them, the reaction temperature is set at 90°C. After reaching the preset temperature and reacting for 5 minutes, take the reaction liquid every 5 minutes and keep the temperature at 25°C, and use a viscometer to test its viscosity. When the viscosity of the reaction liquid is greater than or equal to When the temperature is 1000Pa·S, stop heating and let the reaction liquid cool down naturally;

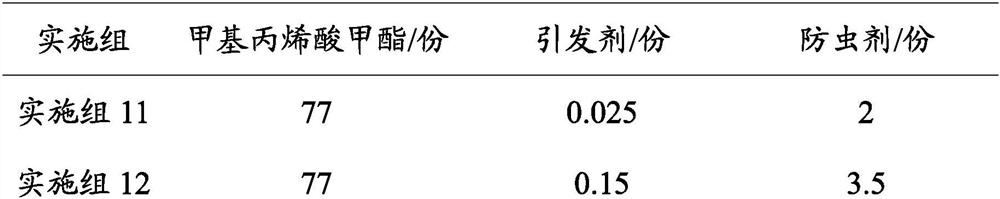

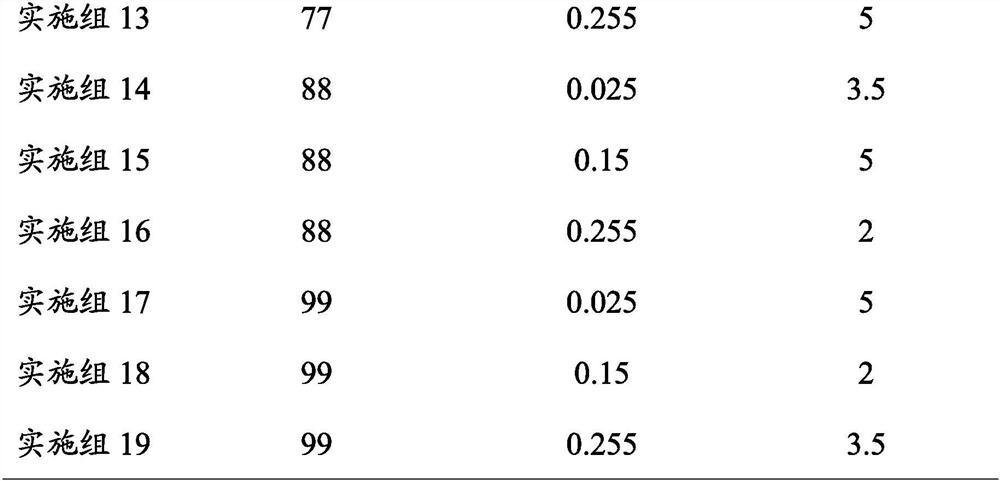

[0036] 2) Add 66-88 parts of methyl methacrylate, 0.02-0.24 parts of azobisisobutyronitrile initiator, 2 parts of divinylbenzene, and 2-5 parts of insect repellent to the react...

Embodiment 2

[0055] The application provides an insect-proof polymethyl methacrylate and a preparation method thereof, the preparation method comprising the steps of:

[0056] 1) Mix 9-11 parts of methyl methacrylate and 0.005-0.015 parts of azobisisobutyronitrile initiator uniformly at a temperature not exceeding 40°C, fully dissolve them, put them into a reaction kettle and heat to react to obtain a reaction liquid; Among them, the reaction temperature is set at 85°C. After reaching the preset temperature and reacting for 5 minutes, take the reaction solution every 5 minutes and keep the temperature at 25°C, and use a viscometer to test its viscosity. When the viscosity of the reaction solution is greater than or equal to When the temperature is 1000Pa·S, stop heating and let the reaction liquid cool down naturally;

[0057] 2) Add 66-88 parts of methyl methacrylate, 0.02-0.24 parts of azobisisobutyronitrile initiator, 2 parts of divinylbenzene, and 2-5 parts of insect repellent to the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com