A self-healing plugging material for regenerative roof and its preparation method

A technology of plugging materials and regenerated roofs, which is applied in shaft equipment, mining equipment, earthwork drilling and mining, etc., to achieve the effects of enhancing water retention capacity, preventing expansion and deformation, and increasing strength and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

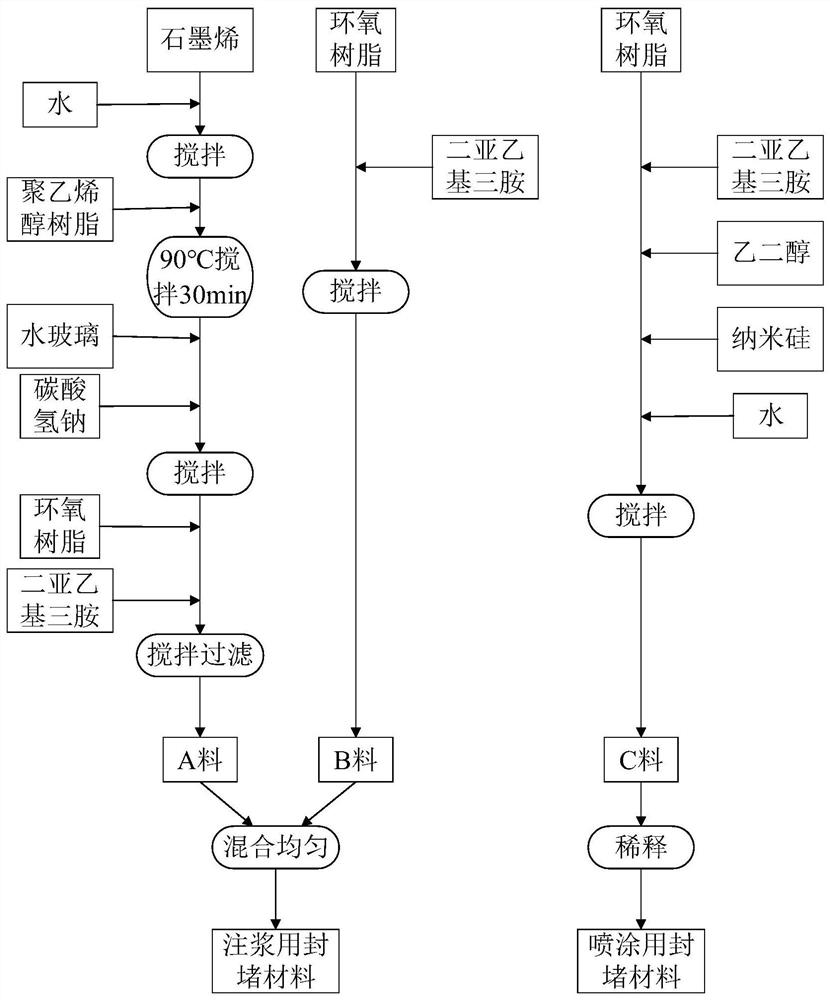

[0025] Embodiment 1: concrete preparation process is:

[0026] A. Add 1 part of graphene to 110 parts of distilled water and stir evenly according to the number of parts by mass, add 21 parts of polyvinyl alcohol resin to the mixed solution and stir for 30 minutes at 90°C, then add 3 parts of water glass and 10 parts of bicarbonate Stir the sodium evenly. At this time, the water glass and sodium bicarbonate react to form a gel. Finally, add 0.7 parts of epoxy resin and stir until particles appear. Add 0.1 part of diethylenetriamine and stir evenly. Oxygen resin wraps the surface of the gel, and through the curing effect of diethylenetriamine on the epoxy resin, thereby forming micron-sized microcapsule particles, which are filtered for 1 hour to prepare material A; the capsule of each micron-sized microcapsule particle The wall thickness is 1-3 μm, and the diameter is 10-40 μm;

[0027] B. Prepare B material by uniformly mixing 100 parts of epoxy resin and 12 parts of diethyl...

Embodiment 2

[0030] Embodiment 2: concrete preparation process is:

[0031] A. Add 3 parts of graphene to 120 parts of distilled water and stir evenly according to the number of parts by mass, add 23 parts of polyvinyl alcohol resin to the mixture and stir for 30 minutes at 90°C, then add 4 parts of water glass and 10 parts of bicarbonate Stir the sodium evenly. At this time, the water glass and sodium bicarbonate react to form a gel. Finally, add 1 part of epoxy resin and stir until particles appear. Add 0.2 parts of diethylenetriamine and stir evenly. Oxygen resin wraps the surface of the gel, and through the curing effect of diethylenetriamine on the epoxy resin, thereby forming micron-sized microcapsule particles, which are filtered for 1 hour to prepare material A; the capsule of each micron-sized microcapsule particle The wall thickness is 1-3 μm, and the diameter is 10-40 μm;

[0032] B. According to the mass parts, 110 parts of epoxy resin and 13 parts of diethylenetriamine are ev...

Embodiment 3

[0035] Embodiment 3: concrete preparation process is:

[0036] A. Add 7 parts of graphene to 110 parts of distilled water and stir evenly according to the number of parts by mass, add 28 parts of polyvinyl alcohol resin to the mixed solution and stir for 30 minutes at 90°C, then add 10 parts of water glass and 30 parts of bicarbonate Stir the sodium evenly. At this time, the water glass and sodium bicarbonate react to form a gel. Finally, add 1.5 parts of epoxy resin and stir until particles appear. Add 0.2 parts of diethylenetriamine and stir evenly. Oxygen resin wraps the surface of the gel, and through the curing effect of diethylenetriamine on the epoxy resin, thereby forming micron-sized microcapsule particles, which are filtered for 1 hour to prepare material A; the capsule of each micron-sized microcapsule particle The wall thickness is 1-3 μm, and the diameter is 10-40 μm;

[0037] B. According to the mass parts, 120 parts of epoxy resin and 14 parts of diethylenetria...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com