Antibacterial melt-blown cloth and preparation method and application thereof

A technology of melt-blown cloth and antibacterial layer, which is applied to the field of antibacterial melt-blown cloth and its preparation, can solve the problems of sterilization failure, electrostatic discharge, and the sterilization effect of electrostatic adsorption is not long-lasting, and achieves long-lasting effect, long service life and good quality. Electrical conductivity and bacteriostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Silver-zinc phosphate glass materials, in parts by mass, include the following raw materials:

[0044] 20 parts of ZnO, Ag 2 O 1 part, P 2 o 5 35 parts, Na 2 O 14 servings.

[0045] The preparation method of silver zinc phosphate glass material is as follows:

[0046] 1) ZnO, Ag 2 O.P 2 o 5 with Na 2 O mixed and melted at 1000°C;

[0047] 2) cooling, pulverizing, and sieving after melting to obtain a silver-zinc-phosphate glass material with a particle size of no more than 10 μm. The silver-zinc-phosphate glass material has a stable structure and can withstand high temperatures above 550°C.

[0048] Detection of acute toxic effects of silver zinc phosphate glass materials on experimental animals:

[0049] Choose 4 healthy rats, 180-220g, half male and half male, and fast overnight before the test.

[0050] The silver-zinc phosphate glass material was made into a suspension with water, administered orally at 1 mL / 100 g, and the poisoning performance and death ...

Embodiment 2

[0056] A kind of antibacterial masterbatch, every 30g raw material is as follows:

[0057] 21g of polypropylene, 0.6g of silver zinc phosphate glass material in Example 1, 6g of graphene, 1.2g of butyl titanate, pentaerythritol tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate ester] 0.6g, polyvinylpyrrolidone 0.6g.

[0058] The preparation method of antibacterial masterbatch is as follows: melt polypropylene at 250°C, add silver zinc phosphate glass material, graphene, butyl titanate, tetrakis[β-(3,5-di-tert-butyl-4-hydroxybenzene Base) pentaerythritol propionate] and polyvinylpyrrolidone, mix uniformly, cool and cut to obtain antibacterial masterbatch.

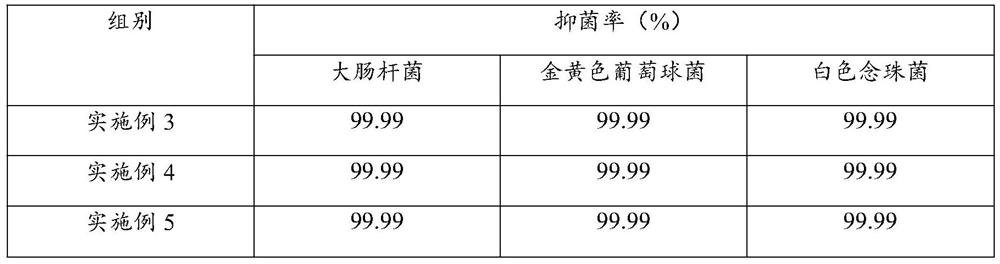

Embodiment 3

[0060] A kind of antibacterial melt-blown cloth, every 120g raw material is as follows:

[0061] Polypropylene 80g, maleic anhydride grafted polypropylene 10g, embodiment 2 antibacterial masterbatch 30g;

[0062]The preparation method of antibacterial melt-blown cloth is as follows:

[0063] Mix polypropylene, maleic anhydride-grafted polypropylene and antibacterial masterbatch, melt at 250°C, spin and lay the net to make 20g / m 2 Antibacterial melt-blown cloth can be used as a sterilization filter material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com