Anti-cracking asphalt concrete composite pavement structure

A technology of asphalt concrete and combined pavement, which is applied to cohesive pavement paved on site, roads, roads, etc., which can solve the problems of easy cracking of asphalt concrete pavement, improve crack resistance, avoid cracking, and improve roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

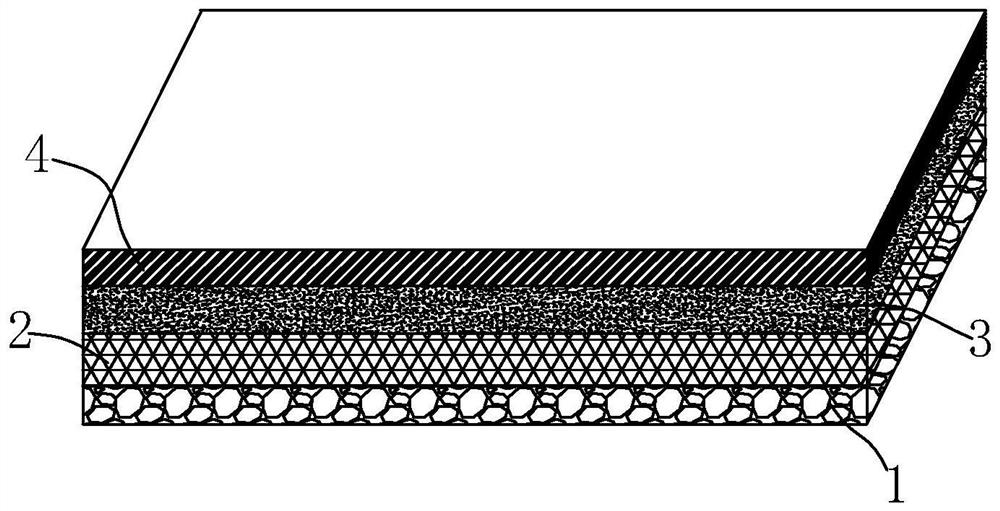

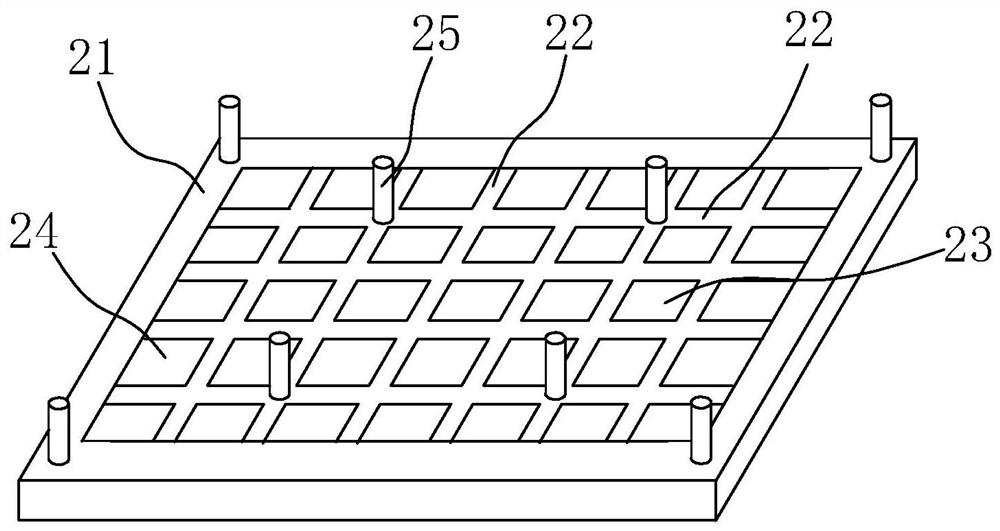

[0027] Such as figure 1 It is a structural schematic diagram of the anti-cracking asphalt concrete composite pavement structure of the present invention, including a gravel road base 1, a support layer 2 laid on the top of the gravel road base, a concrete layer 3 laid on the top of the support layer, and a concrete layer laid on the concrete layer pavement layer 4 above; figure 2 It is a structural schematic diagram of the supporting layer of the present invention, the supporting layer includes a steel frame frame 21 placed horizontally above the gravel road base and several supporting rods 22 horizontally arranged inside the steel frame frame, and both ends of the supporting rod are connected to The steel frame is fixedly connected, the height of the support rod is equal to the height of the frame, the first groove 23 formed between the support rod and the support rod, and the second groove formed between the support rod and the steel frame 24 are all filled with adhesive, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com