Fan provided with bent blades

A blade and fan technology, applied in the field of automobile engine cooling, can solve the problems of increasing the idle power of blades, increasing the noise of the fan, and losing the effective air volume, and achieves the effect of reducing the loss of air volume, reducing noise, and improving aerodynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

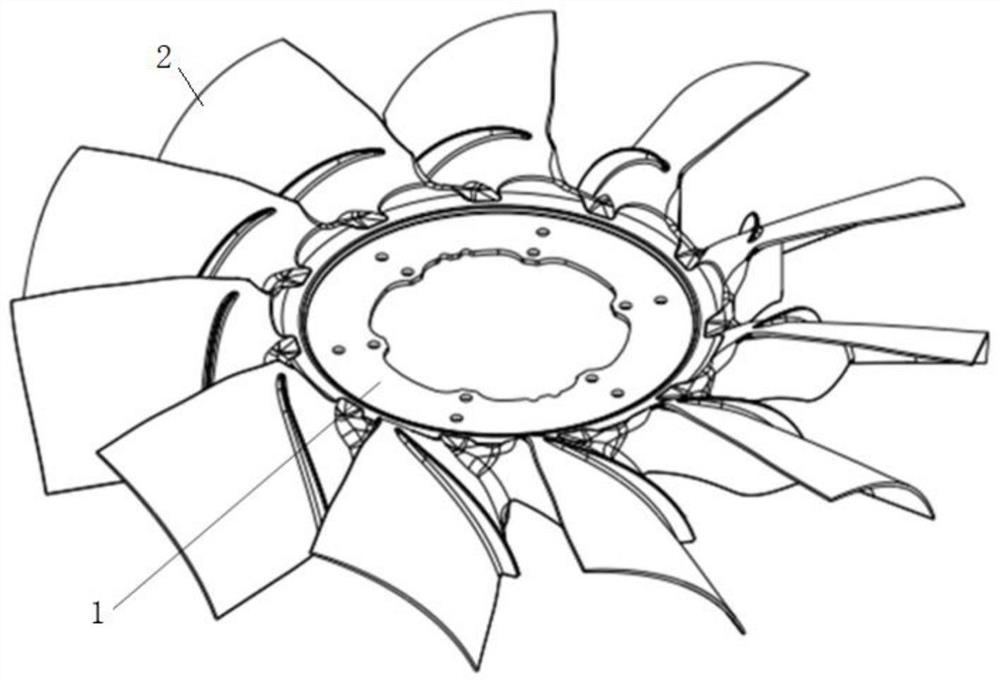

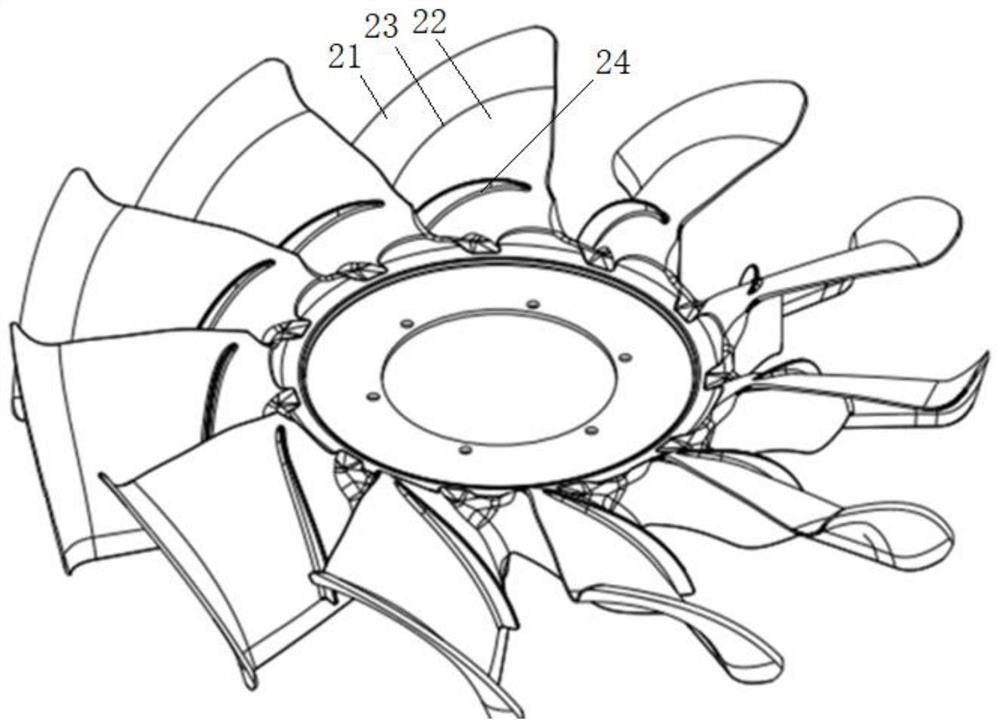

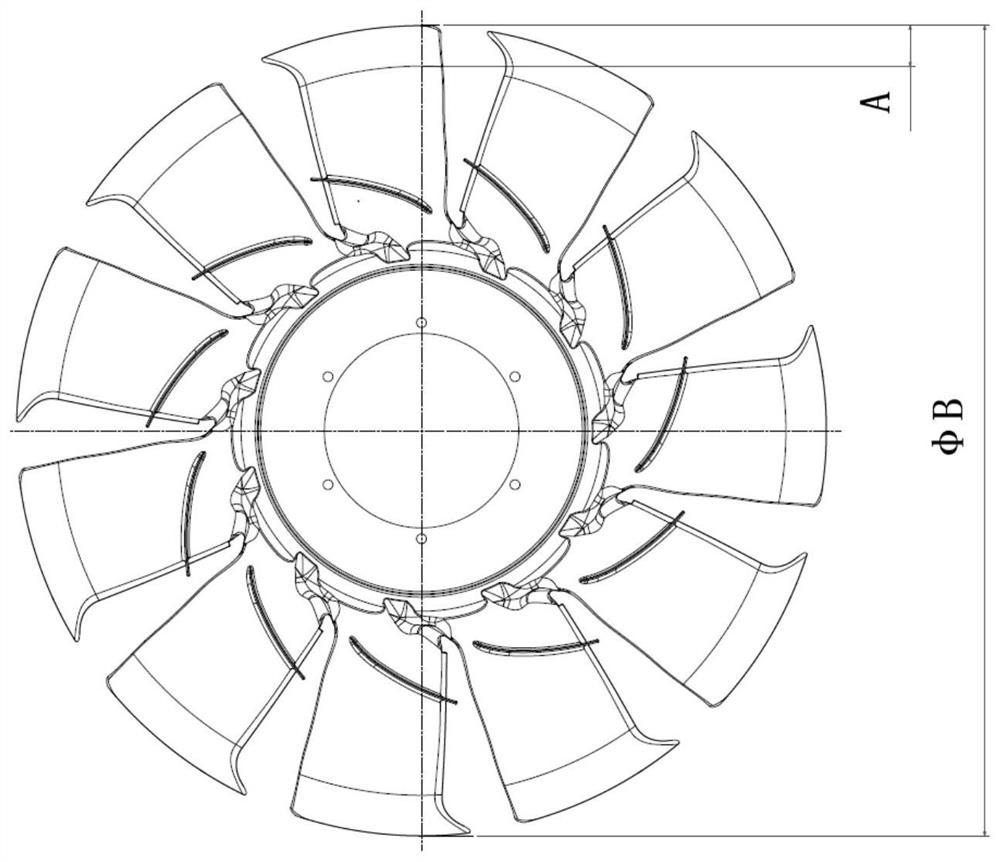

[0020] like Figure 2-4 As shown, a blade-bending fan of the present invention includes a fan blade and an insert 1, the fan blade is a plastic part, and the insert 1 is a high-strength metal part. The fan blade is a rotating part and is used to dissipate heat to the engine system. The clutch assembly and insert 1 are connected by screws, and the flange shaft is connected to the engine to transmit the input torque of the engine.

[0021] The fan blade includes a hub and blades 2, and a plurality of blades 2 are uniformly arranged on the hub, and the roots of the plurality of blades 2 are all arranged on the hub. The end of each blade 2 is equally bent to the windward side of the fan at the bending transition line 23, and the blade 2 is divided into two parts at the bending transition line 23, which are respectively the bending part 21 at the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bend angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap