Battery

A battery and micro-battery technology, applied in secondary battery manufacturing, battery pack parts, circuits, etc., can solve problems such as difficulty in passing large current, difficulty in realizing automation, difficulty in battery assembly, etc., so as to improve heat dissipation capacity and realize automatic production , the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

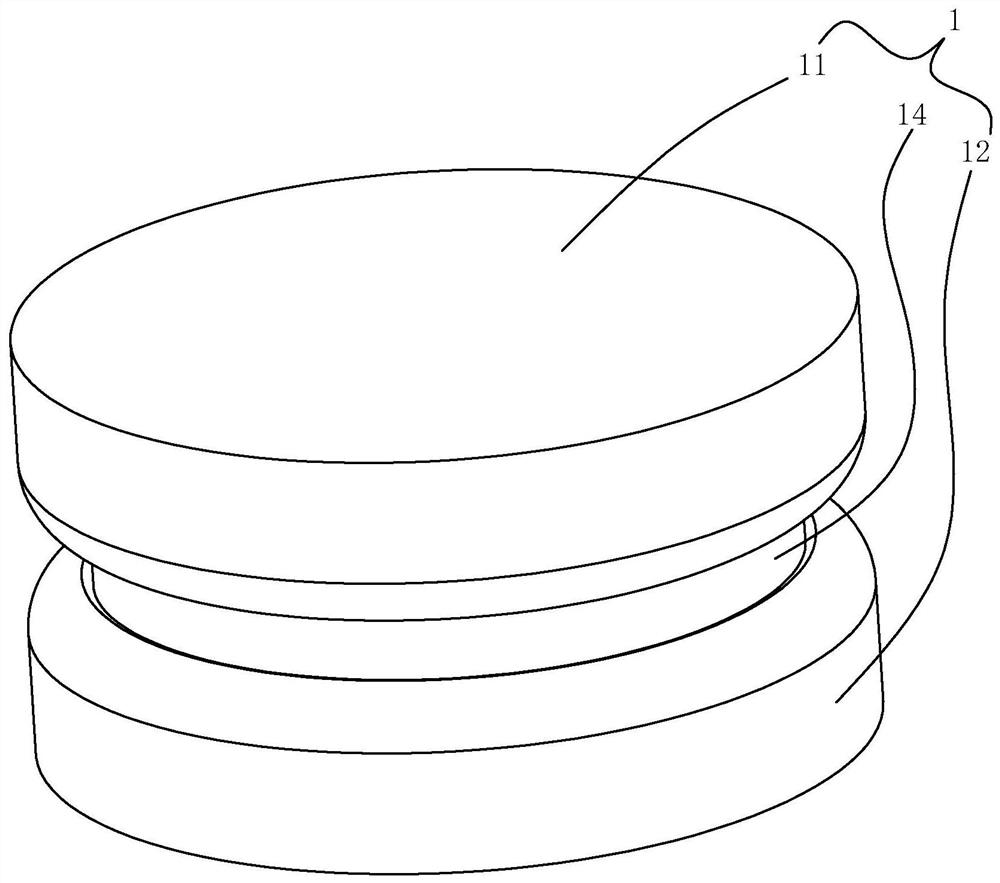

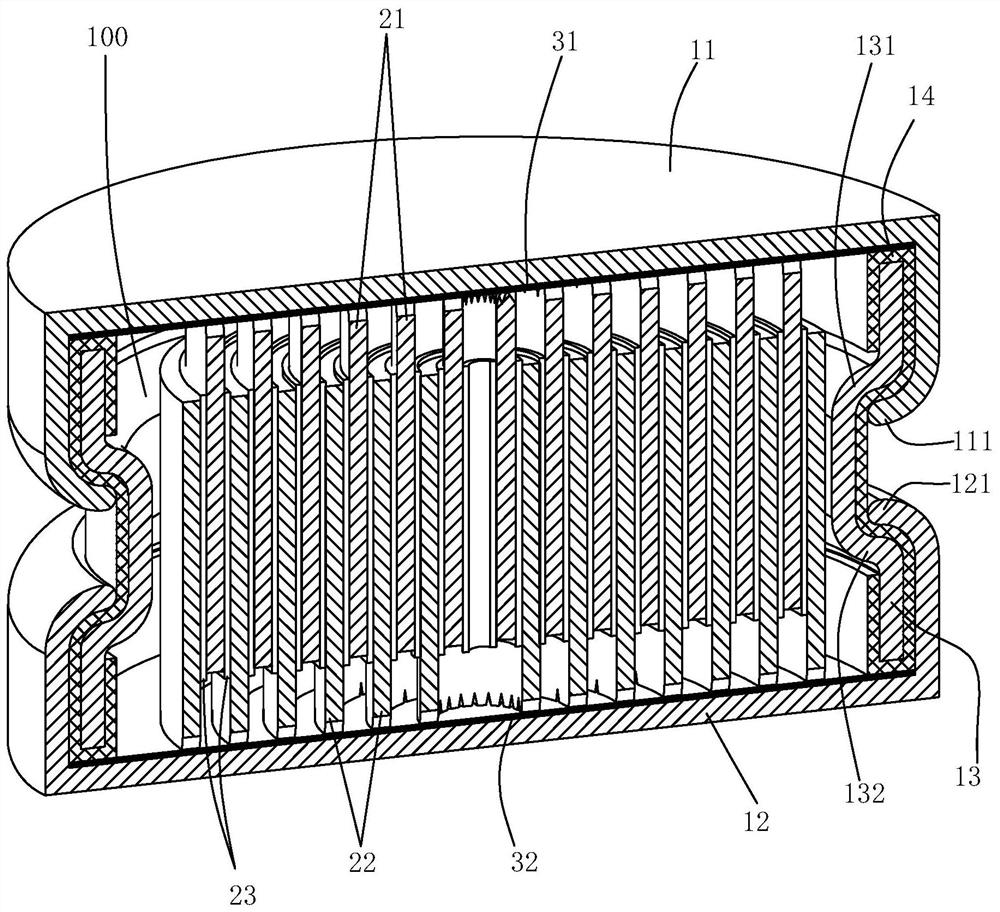

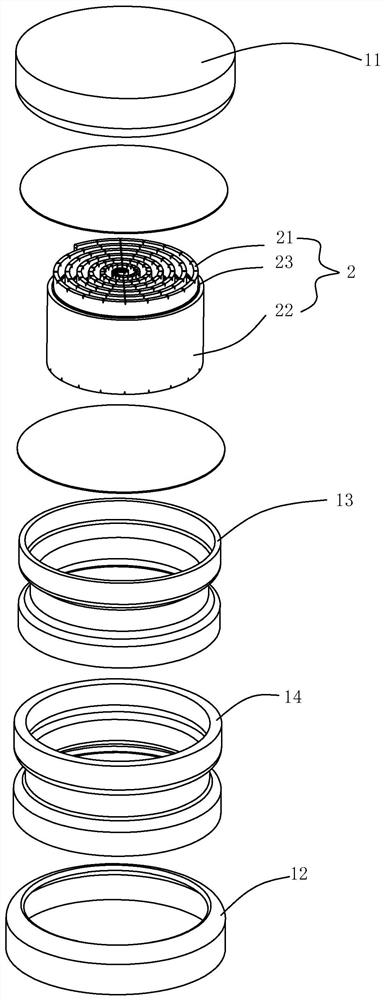

[0030] like Figure 1 to Figure 3 As shown, a battery of this embodiment, the micro battery includes a casing 1 and a battery cell 2, and the casing 1 includes: a first pole casing 11 made of a conductive material, a second pole casing 11 made of a conductive material Diode shell 12 and base shell 13 made of conductive material, the first pole shell 11 is sealed and connected to one end of the base shell 13, and the second pole shell 12 is sealed and connected to the other end of the base shell 13, An insulating layer 14 made of insulating material is provided between the base shell 13 and the first pole shell 11 and the second pole shell 12. The first pole shell 11, the second pole shell 12 and the base shell 13 There is a cavity 100 for accommodating the electric core 2 therebetween, the electric core 2 includes a first pole piece 21 and a second pole piece 22 wound with each other, and the first pole piece 21 and the second pole piece 22 Next to each other, and a separator...

Embodiment 2

[0036] like Figure 4 to Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that: this embodiment is provided with an outwardly bent boss A112 on the first pole shell 11; The boss B122; this design can facilitate automatic assembly.

Embodiment 3

[0038] like Figure 7 to Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that: the first pole shell 11 is provided with a reinforcement part A113 for improving the sealing performance between the first pole shell 11 and the upper edge of the base shell 13, so The reinforcement part A113 is in a "U" shape, and the upper edge of the base case 13 is stuck in the reinforcement part A113; The reinforcing part B123 with sealing performance between them, the reinforcing part B123 is in the shape of "U", and the lower end edge of the base shell 13 is stuck in the reinforcing part B123. Adopting this design can improve the sealing performance between the first pole shell, the second pole shell and the two ends of the base shell, improve the effectiveness and strength of the seal, and reduce the proportion of battery leakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com