Hydraulic drive type foot type bionic humanoid robot

A humanoid robot, driven technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problem that the number of degrees of freedom of the leg mechanism cannot meet high flexibility and high obstacle avoidance ability, restrict the walking ability and engineering application of biped robots, Problems such as motion accuracy and response speed are limited, to achieve the effect of high power-to-weight ratio, strong load capacity, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

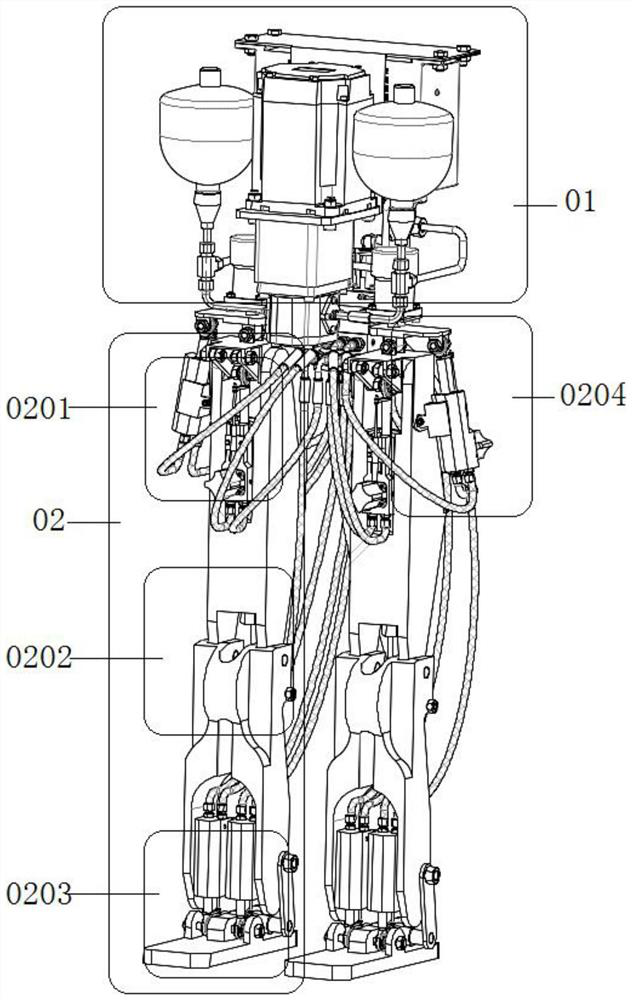

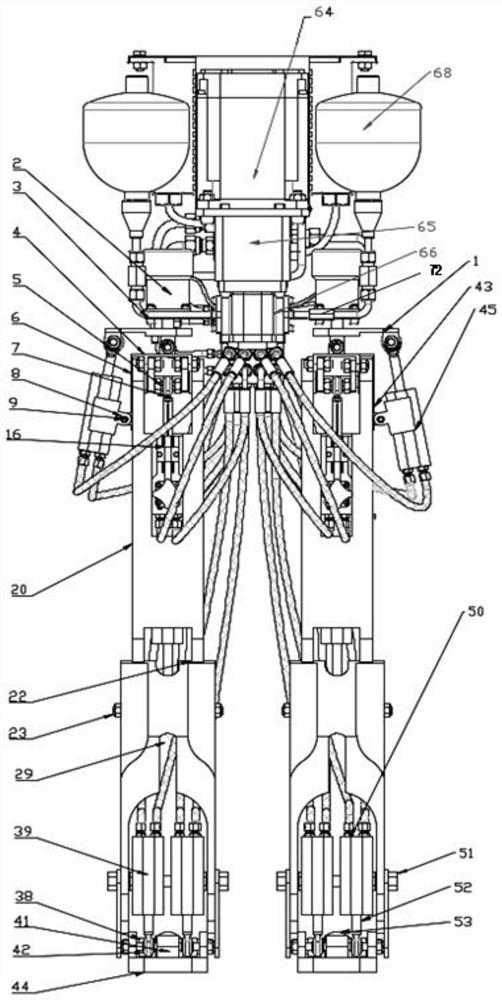

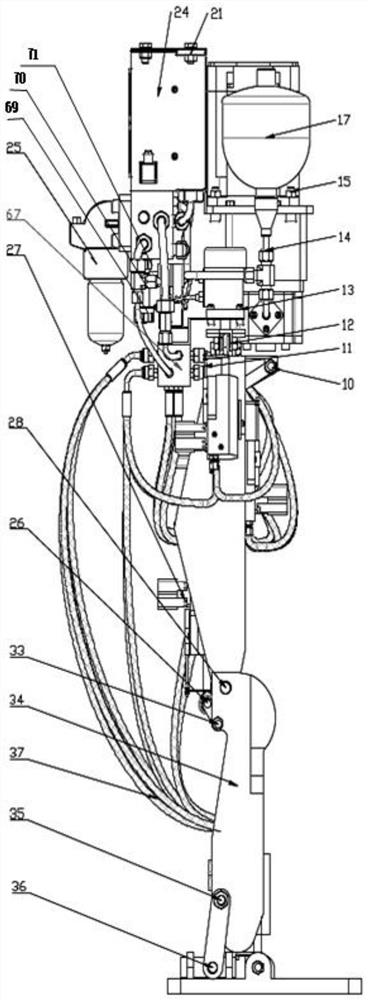

[0033] like Figure 1-4 As shown, this embodiment provides a hydraulically driven footed bionic humanoid robot, which mainly includes a hydraulic pump station 01, a leg mechanical structure 02, a hip joint 0201, a knee joint 0202, an ankle joint 0203, and a hydraulic drive unit 0204; The station 01 is fixed on the upper limb connecting frame 1 through the connecting parts, and the mechanical structure of the leg 02 is mainly divided into three joints according to the principle of human bionics. The hip joint 0201 has three degrees of freedom, which can realize the rotation, side swing and pitching of the leg structure. The hydraulic swing rod 2 rotates to drive the rotation of the hip joint 0201. The linear motion in the servo cylinder 55 drives the side swing and pitch motion of the hip joint 0201; the knee joint 0202 has one degree of freedom, which can realize the pitching action of the lower leg, and the servo cylinder cylinder rod 60 in the hydraulic drive unit 0204 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com