Low-cost, high-strength and high-toughness mid-entropy alloy and preparation method

A high-strength, high-toughness, entropy alloy technology, applied in the field of low-cost, high-strength, high-toughness medium-entropy alloys and preparation, can solve the problems of incompatibility of strength and plasticity, high cost, etc., and achieve excellent thermal stability, high repeatability, Reasonable and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

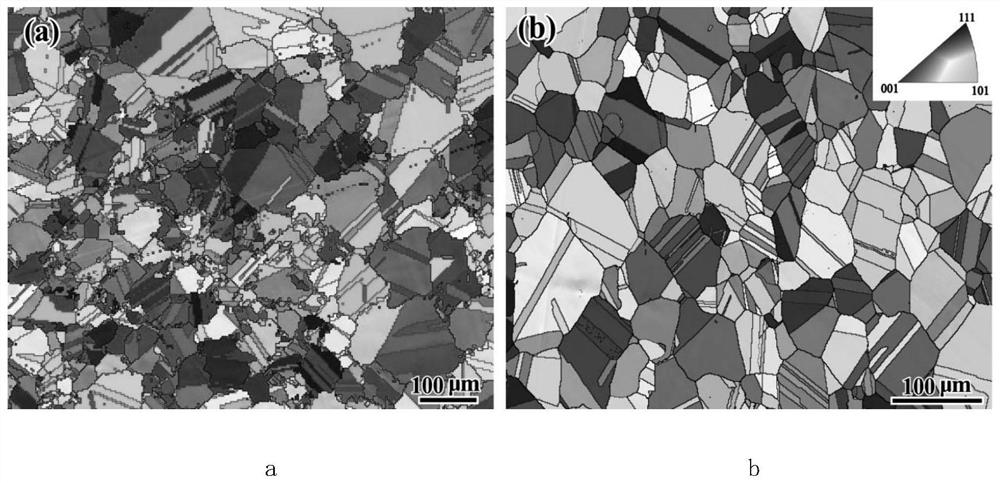

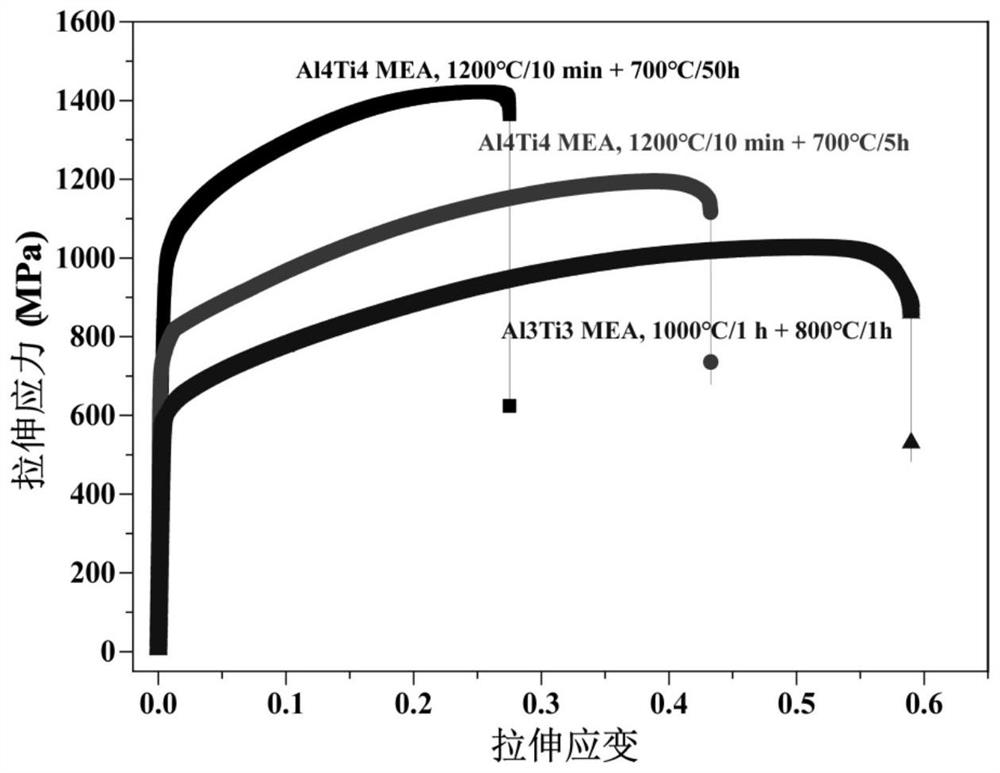

[0041] A low-cost, high-strength, high-toughness medium-entropy alloy, the chemical formula of which is Ni 47 Fe 23.5 Cr 23.5 al 3 Ti 3 , Abbreviated as Al3Ti3 alloy, in which the ratio of each element is mole (atomic) percentage. Concrete preparation process is as follows:

[0042](1) Pretreatment and batching of raw materials: use mechanical grinding to remove the oxide scales on the surface of Ni, Fe, Cr, Al and Ti elements, and use acetone and alcohol solutions for ultrasonic cleaning in turn, and then dry them for later use. Weigh and batch according to the nominal composition of the alloy, and the total weight of raw materials is 2Kg.

[0043] (2) Melting: Place Ni, Fe, and Cr elements in a vacuum induction melting furnace and heat to 1650°C for 15 minutes, then add Al and Ti elements and hold for 10 minutes, then pour the melt into a steel mold to cool.

[0044] (3) Homogenization treatment: The ingot of the medium-entropy alloy is heat-treated at 1200° C. / 10 h, f...

Embodiment 2

[0050] A low-cost, high-strength, high-toughness medium-entropy alloy, the chemical formula of which is Ni 46 Fe 23 Cr 23 al 4 Ti 4 , Simplified Al4Ti4 alloy, in which the ratio of each element is mole (atomic) percentage. The preparation process is as follows:

[0051] (1) Pretreatment and batching of raw materials: use mechanical grinding to remove the oxide scales on the surface of Ni, Fe, Cr, Al and Ti elements, and use acetone and alcohol to perform ultrasonic cleaning in sequence, and then dry them for later use. Weigh according to the nominal composition of the alloy, and the total weight of raw materials is 2Kg.

[0052] (2) Melting: Place Ni, Fe, and Cr elements in a vacuum induction melting furnace and heat to 1650°C for 15 minutes, then add Al and Ti elements and hold for 10 minutes, then pour the melt into a steel mold to cool.

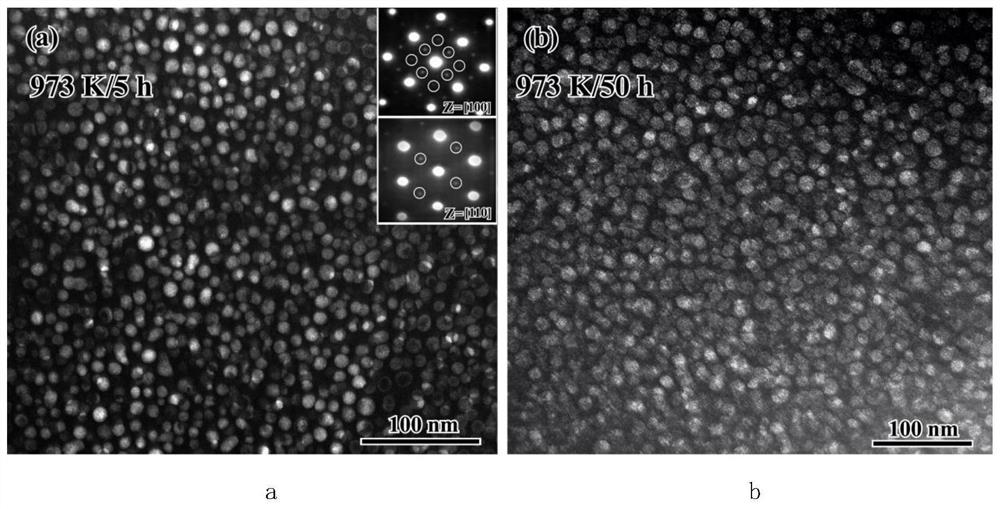

[0053] (3) Homogenization treatment: The ingot of the medium-entropy alloy is heat-treated at 1200° C. / 10 h, followed by water quen...

Embodiment 3

[0059] A low-cost, high-strength, high-toughness medium-entropy alloy, the chemical formula of which is Ni 46 Fe 23 Cr 23 al 4 Ti 4 , Abbreviated as Al4Ti4 alloy, in which the ratio of each element is mole percent. The preparation process is as follows:

[0060] (1) Pretreatment and batching of raw materials: use mechanical grinding to remove the oxide scales on the surface of Ni, Fe, Cr, Al and Ti elements, and use acetone and alcohol solutions for ultrasonic cleaning in turn, and then dry them for later use. Weigh according to the nominal composition of the alloy, and the total weight of raw materials is 500g.

[0061] (2) Melting: Place Ni, Fe, and Cr elements in a vacuum induction melting furnace and heat to 1650°C for 15 minutes, then add Al and Ti elements and hold for 10 minutes, then pour the melt into a steel mold to cool.

[0062] (3) Homogenization treatment: The ingot of the medium-entropy alloy is heat-treated at 1200° C. / 10 h, followed by water quenching. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com