Veneer drying system

A drying system and veneer technology, which is applied in drying, drying machines, wood drying, etc., can solve the problems of poor drying effect, high energy consumption, and large floor space, and achieve saving equipment and material investment, The effect of equipment volume reduction and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly. The veneer drying system of the present embodiment is a device for drying veneer sheets spin-off from wood.

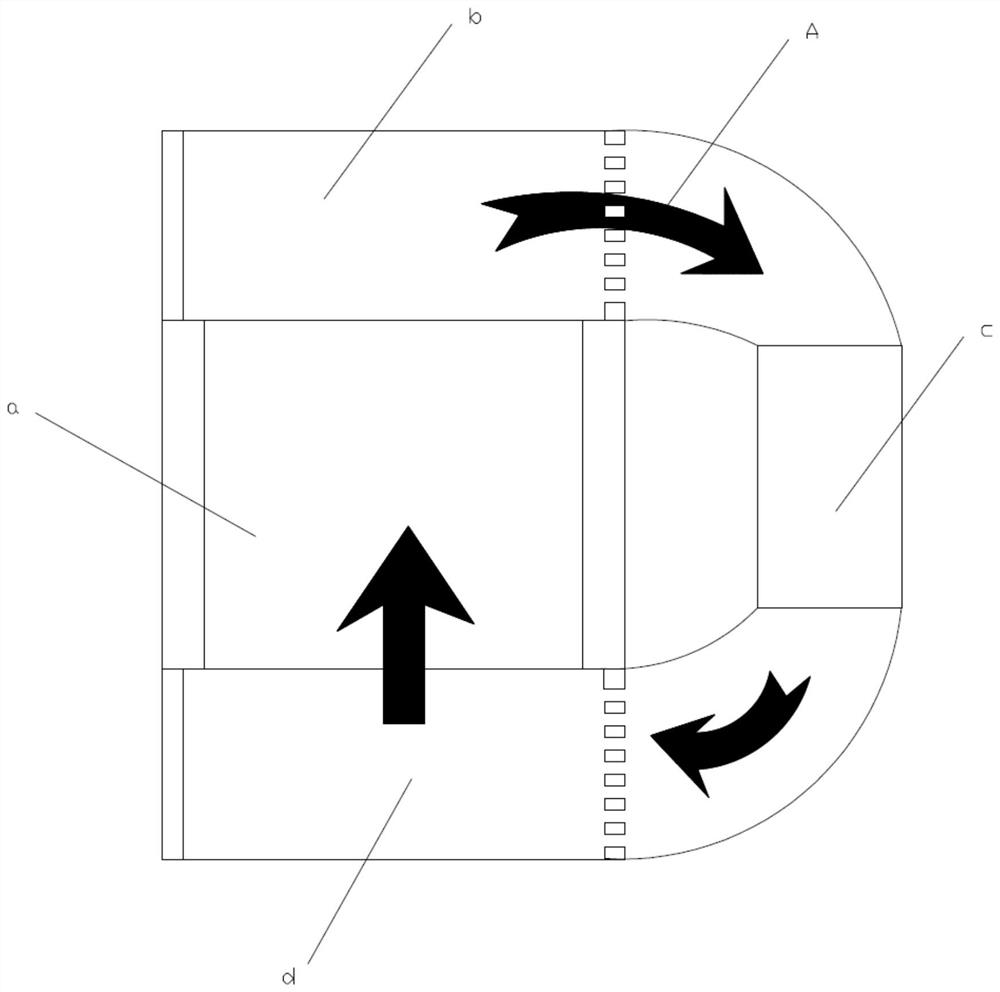

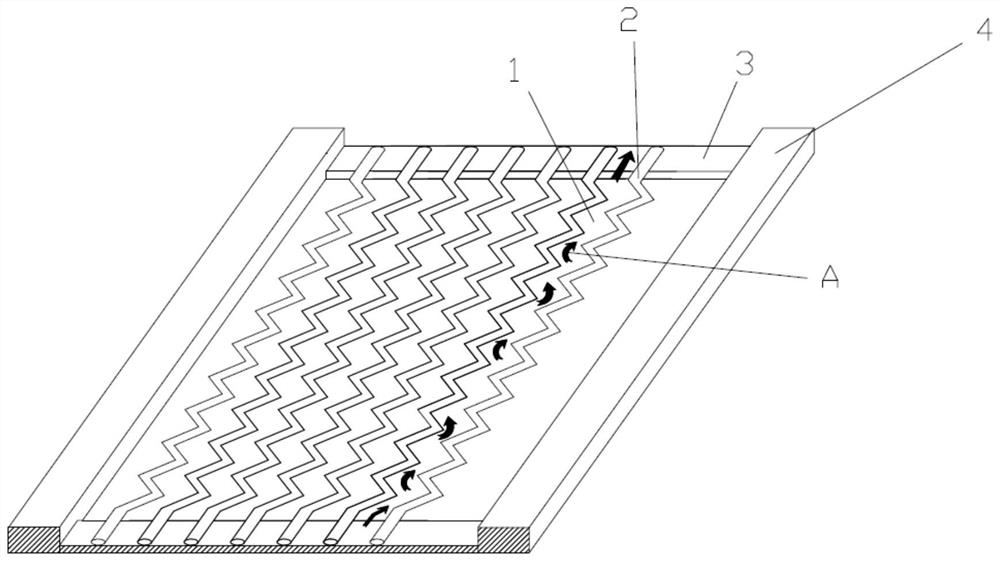

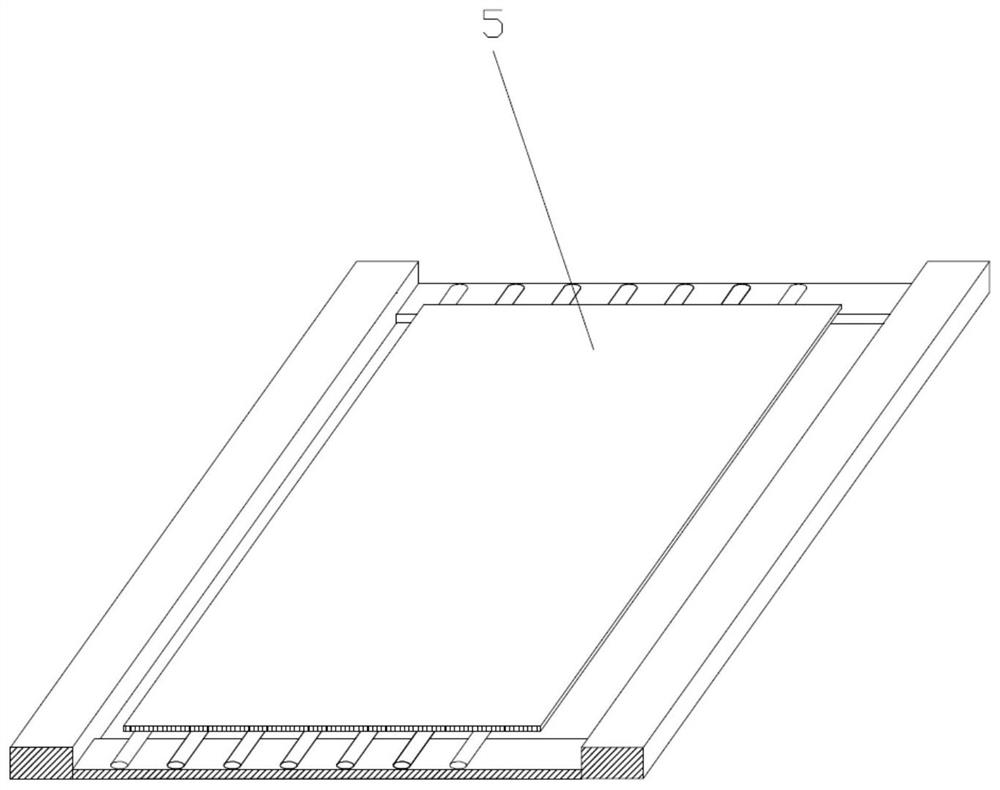

[0038] see figure 1 , the veneer drying system in this embodiment has: a plate frame group a, which is composed of a plurality of veneers 5 and spacers stacked at intervals, a spacer is set between two adjacent veneers 5, veneers 5 and spacers A cracked air passage is formed between them, and the drying gas A passes through the above-mentioned cracked air passage, and then dries the veneer 5; the exhaust chamber b is used to draw the drying gas A containing humidity from the plate frame group a; heat exchange Device b, which uses the hot a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com