Positive plate with special-shaped structure and lithium ion battery comprising positive plate

A positive electrode, positive electrode technology, applied in positive electrodes, structural parts, battery electrodes, etc., can solve problems such as safety hazards, and achieve the effects of improving safety, solving the problem of surface lithium deposition, and reducing polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080]

[0081] The present invention also provides a method for preparing the above-mentioned positive electrode sheet, the method comprising the following steps:

[0082] 1) respectively preparing the slurry for forming the first positive electrode active material layer and the slurry for forming the second positive electrode active material layer;

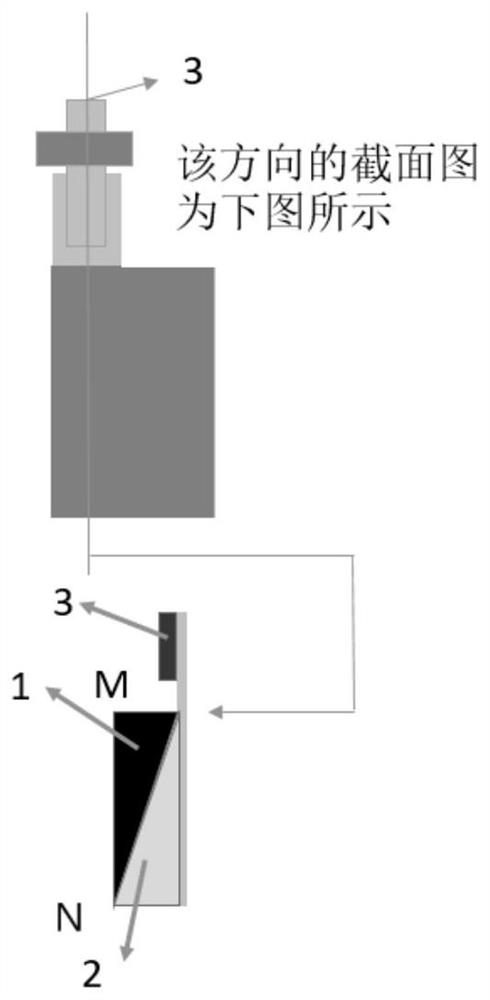

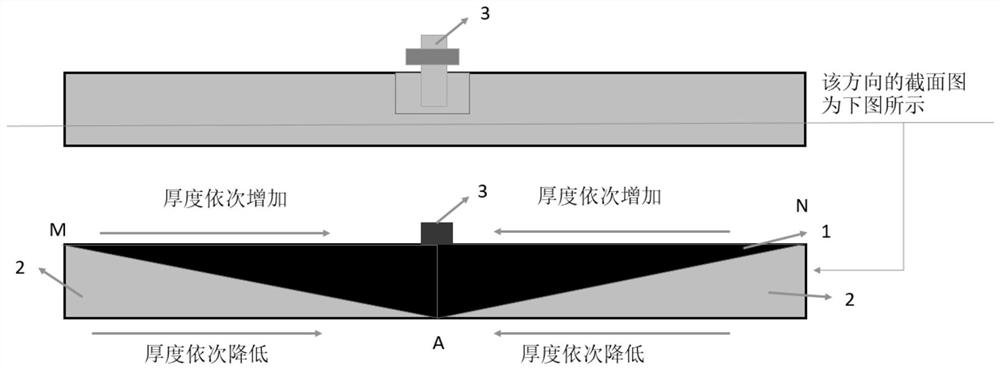

[0083] 2) along the length direction of the positive electrode current collector, set an empty foil area and a coating area on the surface of the positive electrode current collector in turn, and use a double coater to form the slurry of the first positive electrode active material layer and form the second positive electrode active material layer. The slurry is coated on the coating area on the surface of the positive electrode current collector, and the thickness of the first positive electrode active material layer near the empty foil area gradually becomes thicker, and the thickness of the second positive electrode active m...

Embodiment 1

[0119] (1-1) Preparation of the first positive electrode active material slurry: the first positive electrode active material, the first conductive agent and the first binder are added into the stirring tank according to the mass ratio of 97.2:1.5:1.3, according to the known ingredients In the process, NMP solvent is added to prepare the first positive electrode active material slurry, and the solid content of the positive electrode slurry is 70% to 75%;

[0120] (1-2) Preparation of the second positive electrode active material slurry: add the second positive electrode active material, the second conductive agent and the second binder into the stirring tank according to the mass ratio of 97.2:1.5:1.3, according to the known ingredients In the process, NMP solvent is added to prepare the second positive electrode active material slurry, and the solid content of the positive electrode slurry is 70% to 75%;

[0121] (1-3) Preparation of negative electrode active material slurry:...

Embodiment 2-19

[0129] The preparation of the batteries of Examples 2-19 is the same as that of Example 1, except that the compositions of the first positive active material and the second positive active material are different, the particle diameters of the first positive active material and the second positive active material are different, and the The content of the conductive agent in the first positive active material layer and the second positive active material layer is different, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com