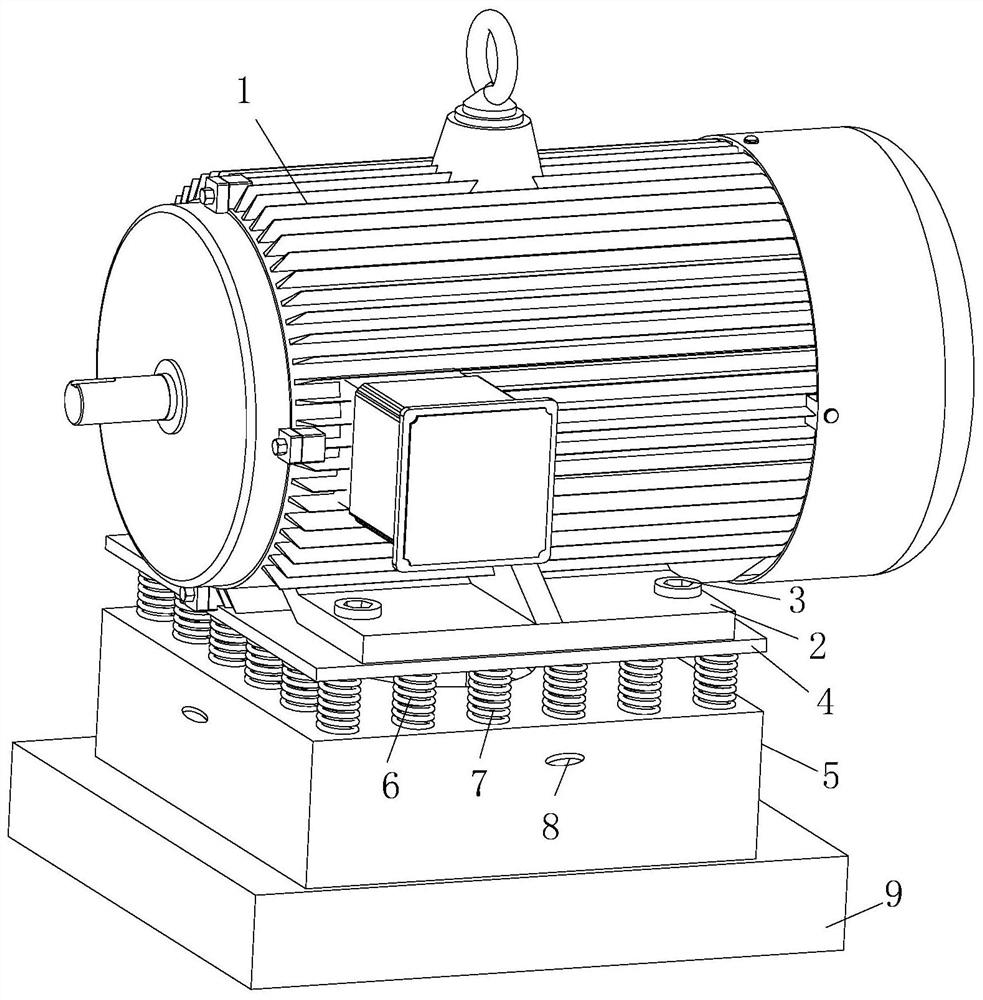

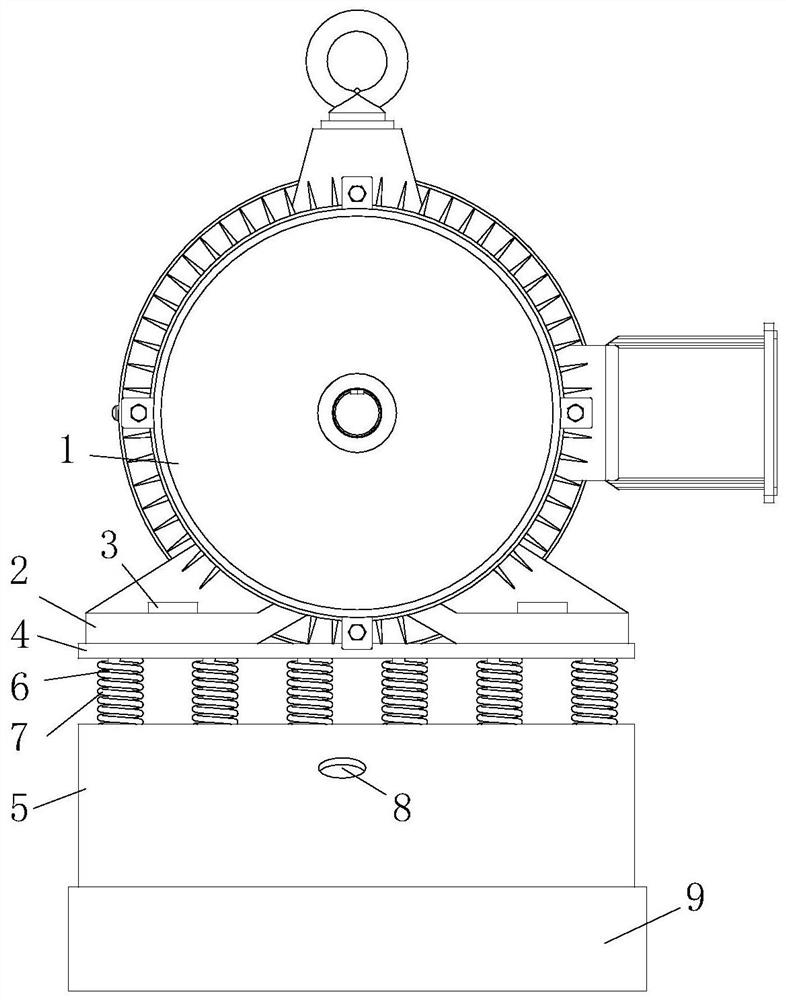

A permanent magnet variable frequency motor for pumps

A variable frequency motor and permanent magnet technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of unstable installation platform, affecting service life, strong vibration of permanent magnet variable frequency motor, etc., and achieve good shock absorption effect , Reduce the vibration intensity, improve the effect of heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

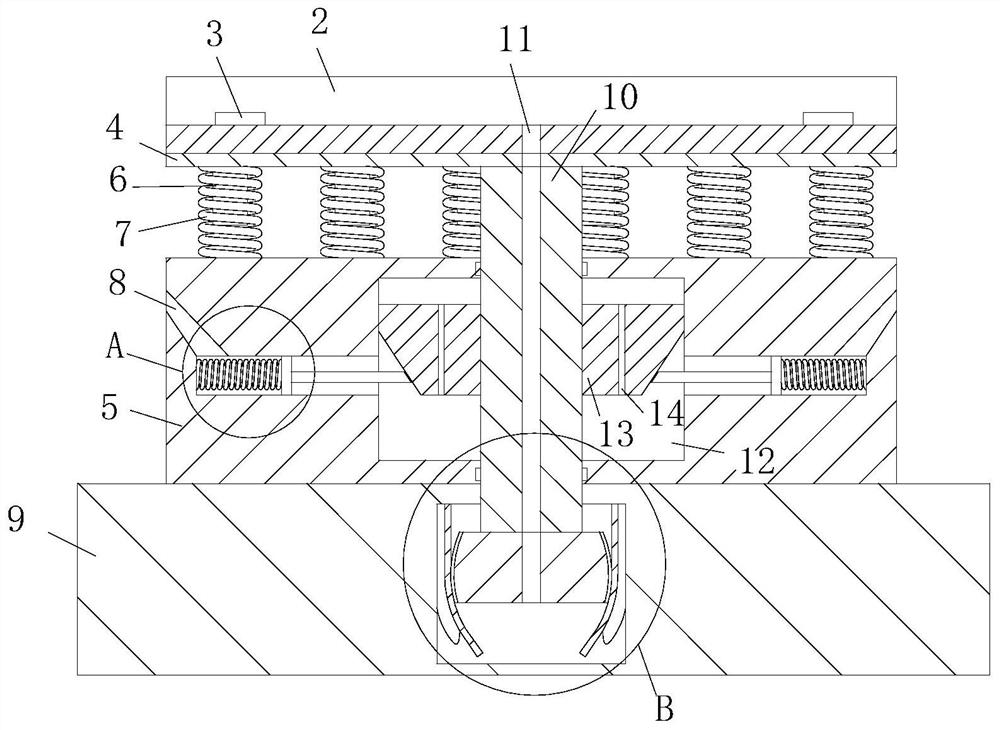

[0028] As an embodiment of the present invention, a plurality of horizontally arranged second chambers 15 are provided on the side wall of the first chamber 12, and second pistons 17 are correspondingly arranged in the second chambers 15. The piston 17 is fixedly provided with a second rod 16 toward the side of the first chamber 12; the lower part of the first piston 13 is in the shape of a truncated cone with a large upper part and a smaller lower part, and the second rod 16 extends into the first chamber 12 and is connected to the first chamber 12. The side wall of the bottom of a piston 13 interferes; the rodless chamber side of the second chamber 15 is provided with a second spring 18 which is resisted with the second piston 17, and the rodless chamber is provided with a The first air hole 8 communicating with the outside world. Through the setting of the second rod 16, when the first rod 10 is pressed down to drive the first piston 13 to move down, since the lower part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com