Automatic feeding and neat cutting type straw cutting and grinding device

An automatic feeding and shredding device technology, applied to cutting equipment, agricultural machinery and implements, applications, etc., can solve the problems of reducing the efficiency of straw cutting and returning to the field, increasing the difficulty of straw returning to the field, and affecting the absorption of nutrients. Simple, low cost, and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

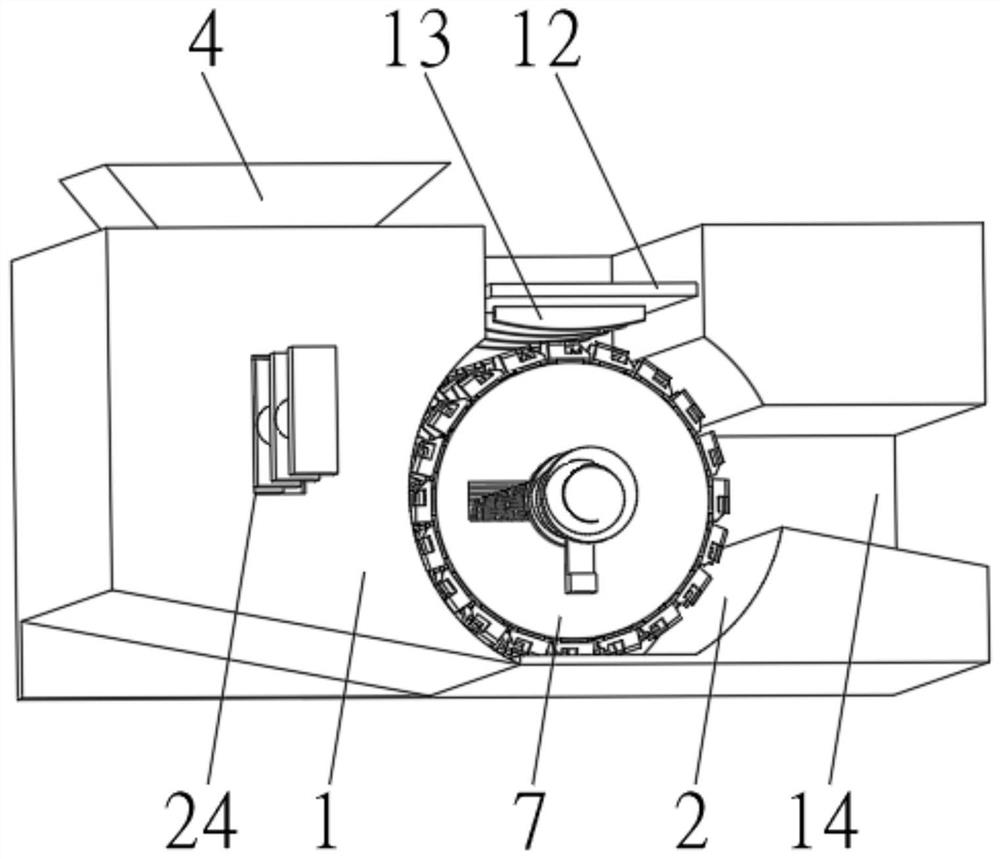

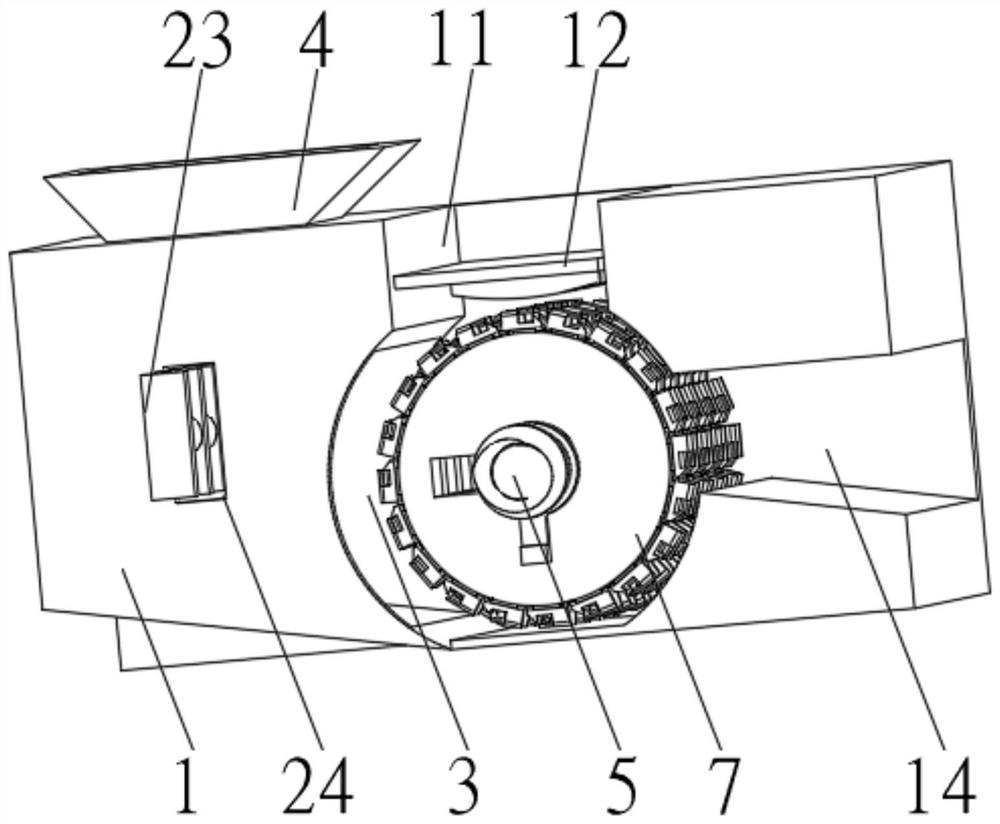

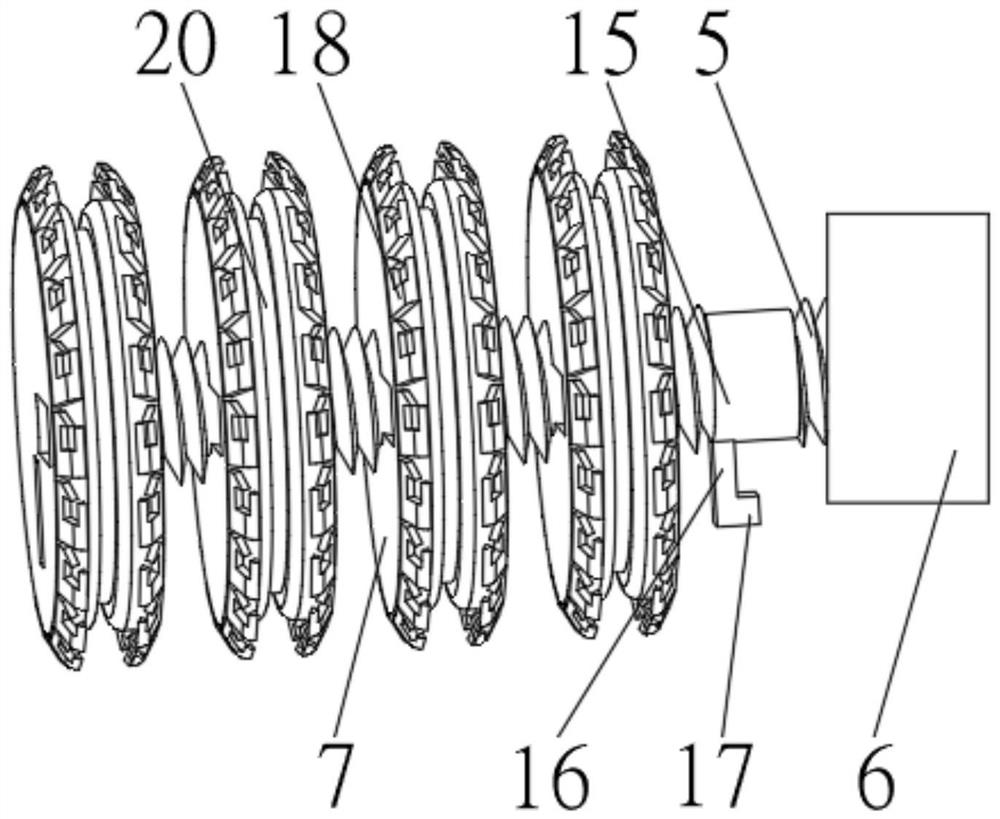

[0031] see Figure 1-7, the present invention provides a technical solution: a straw chopping device that automatically feeds and cuts neatly, comprising a shell 1, a circular chopping groove 2 is provided in the inner middle of the shell 1, and a round groove 2 is provided on one side of the chopping circular groove 2. Storage tank 3, the top of the shell 1 is located above the storage tank 3 and a feed hopper 4 is installed, the feed hopper 4 communicates with the storage tank 3, and a fixed rod 5 is installed between the two sides of the inner wall of the chopping circular tank 2 One side of the casing 1 is fixedly connected with a driving device 6, one end of the fixed rod 5 penetrates to the outside of the casing 1 and is in transmission connection with the driving device 6, the outer side of the fixed rod 5 is uniformly set with a cutting wheel 7, and the outer side of the cutting wheel 7 The grabbing block 8 is evenly installed, the grabbing block 8 is an elastic metal ...

Embodiment 2

[0039] see Figure 1-7 , the present invention provides a technical solution: on the basis of Embodiment 1, the bottom of the inner wall of the material storage tank 3 is slidingly connected with a pusher plate 21, the bottom of the pusher plate 21 is a circular arc plate, and one side of the pusher plate 21 A push rod 22 is fixedly connected, and the push rod 22 penetrates the casing 1 and extends to the outside of the casing 1 .

[0040] The outer side of the push rod 22 is evenly equipped with a baffle 23, and the outer side of the casing 1 is provided with a limit groove 24 that is compatible with the baffle 23. The limit groove 24 communicates with the material storage tank 3, and one side of the push plate 21 passes through The strong spring 25 is fixedly connected with the shell 1 .

[0041] During use, hold the baffle plate 23 and pull the push rod 22 to the outside of the shell 1, turn the push rod 22 and the rear baffle plate 23 is blocked by the shell 1, the pusher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com