Concrete mixing process

A mixing process and concrete technology, applied in mixing plants, cement mixing devices, clay preparation devices, etc., can solve the problems of reducing the environmental protection of concrete mixing devices, reducing work efficiency, endangering life and health, etc., reducing the participation of construction workers, The effect of reducing labor intensity and improving environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

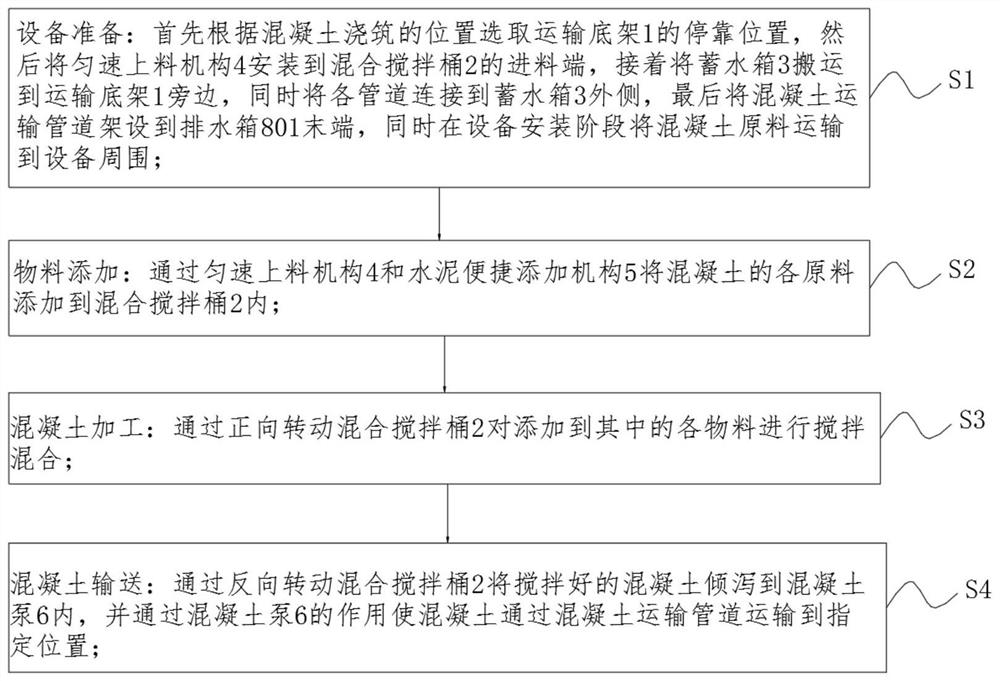

[0045] Example: such as figure 1 As shown, the present invention provides a kind of technical scheme, a kind of concrete mixing process, comprises the steps:

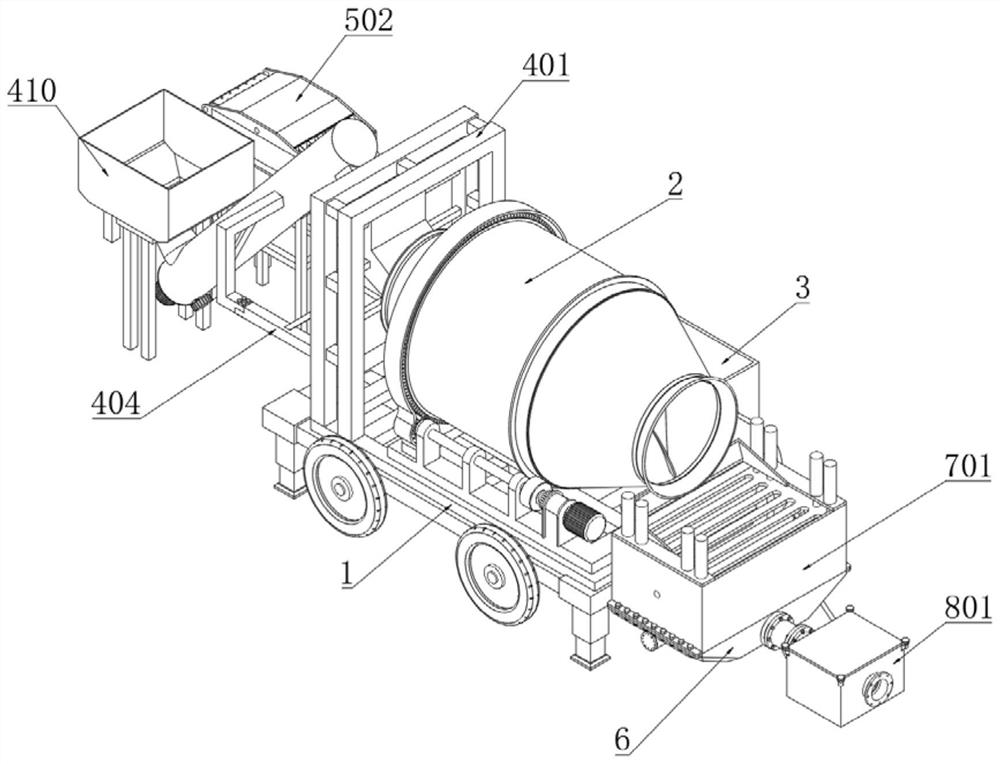

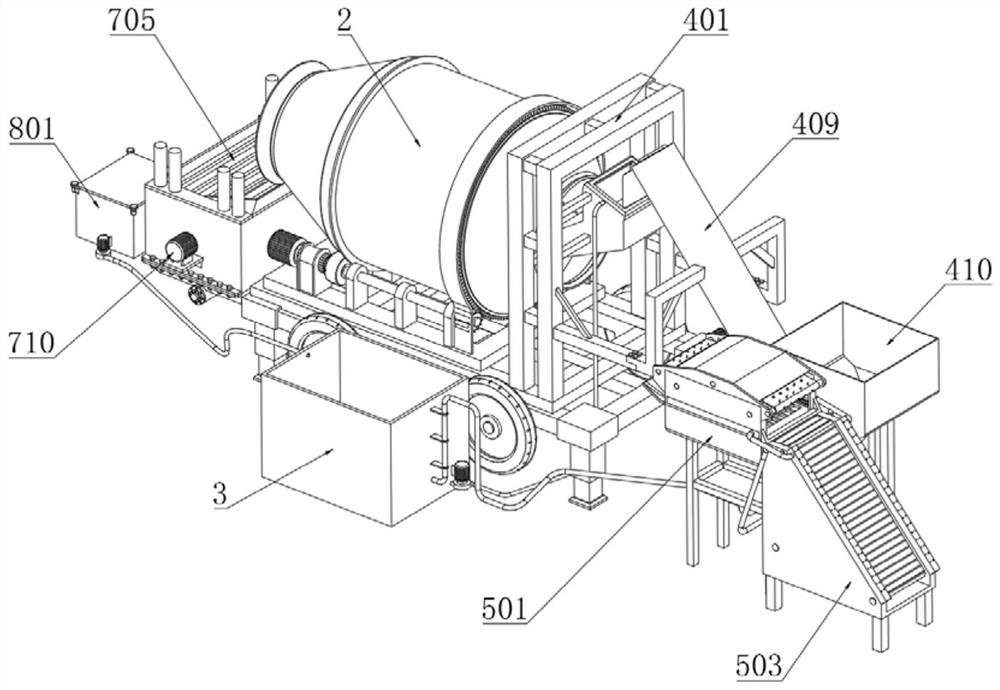

[0046] S1. Equipment preparation: first, select the docking position of the transport chassis 1 according to the position of concrete pouring, then install the uniform feeding mechanism 4 on the feeding end of the mixing tank 2, and then transport the water storage tank 3 to the transport chassis 1 At the same time, each pipeline is connected to the outside of the water storage tank 3, and finally the concrete transportation pipeline is erected to the end of the drainage tank 801, and the concrete raw materials are transported around the equipment during the equipment installation stage;

[0047] S2. Adding materials: adding the raw materials of concrete into the mixing tank 2 through the uniform feeding mechanism 4 and the convenient cement adding mechanism 5;

[0048] S3. Concrete processing: mixing the materials add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com