Zero-leakage magnetic coupling suction type propeller for deepwater working condition ROV and propelling method

A magnetic coupling and adsorption technology, applied in the direction of water action propulsion elements, transmission devices with synchronous propulsion components, and propulsion components, can solve the problems of difficult to achieve precise control, limit the depth of underwater operations, equipment damage, etc. Provides work stability, ease of use, installation and maintenance, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

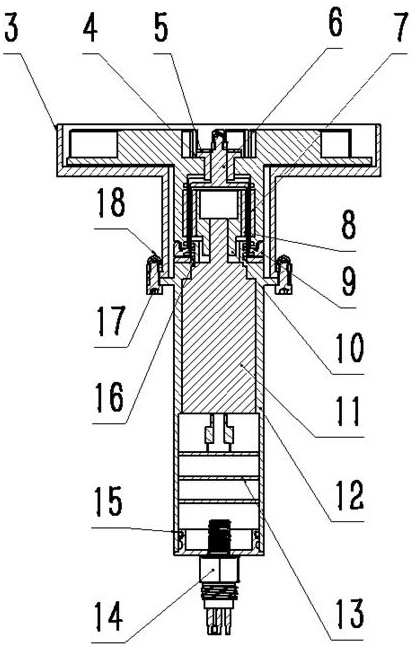

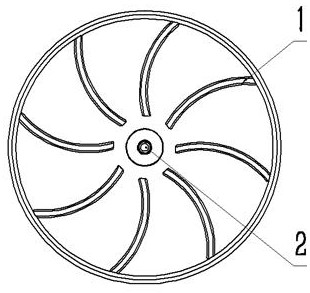

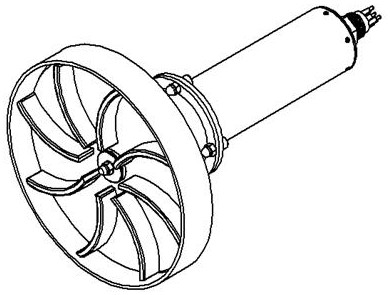

[0032] The present invention provides a zero-leakage magnetic coupling adsorption thruster for ROV in deep water working conditions, comprising: a disc propeller 1, a cap nut 2, a propeller shield 3, a self-lubricating bushing 4, a gasket 5, and a spacer 6. Follower coil magnet 7, driving coil magnet 8, self-lubricating bearing 9, driving coil magnet hub 10, gear motor 11, body shell 12, driver 13, watertight connector 14, sealing ring 15, sealing ring 16, inner hexagon Cylinder head screw 17, cap nut 18.

[0033] The reduction motor 11 and the driver 13 are connected by wires and installed inside the body shell 12. The structure is compact, the transmission distance of electric signals is short, and the signal interference is small.

[0034] The geared motor 11 is independently developed, which eliminates the inconvenience of traditional motor-matching reducer mechanical connection, and has a compact structure and takes up little space.

[0035] Magnetic coupling system: the...

Embodiment 2

[0038] The present invention provides a zero-leakage magnetic coupling adsorption thruster for ROV in deep water working conditions. The watertight connector 14 is fixedly connected to the end of the body shell 12, the exposed part is connected to the land umbilical cable, and the built-in part is connected to the geared motor 11. After electrification, the electric power and electrical signal on the land are transmitted to the geared motor 11 and start to work. After deceleration by the geared motor 11, the output torque is transmitted to the active coil magnet hub 10 to drive its operation, thereby driving the magnet hub fixedly connected to the active coil. The active coil magnet 8 on 10 operates together, and the magnetic force radiated by the magnet itself penetrates the spacer 6 and is transmitted to the follower coil magnet 7, thereby driving the follower coil magnet 7 and its fixedly connected disc propeller 1 together Operation, so as to discharge the local water flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com