Method for treating vinegar auxiliary materials by using steam explosion process to brew mature vinegar

A technology of aged vinegar and steam, which is applied in the preparation of vinegar, etc., to achieve the effects of wide application prospects, high utilization rate of raw materials, and variable fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

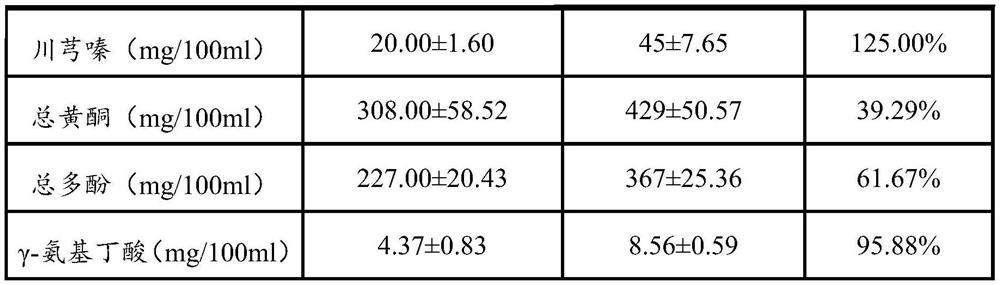

Examples

Embodiment 1

[0026] Embodiment 1 A kind of method utilizing steam explosion process to process vinegar auxiliary material to brew aged mature vinegar

[0027] A method for brewing old mature vinegar by processing vinegar auxiliary materials with a steam explosion process, comprising the following steps:

[0028] (1) Raw material processing: put the bran into a steam explosion tank for steam explosion, the medium used is water vapor, the pressure is 0.2Mpa, the temperature is 120°C, and the maintenance time is 5min to obtain auxiliary materials; the sorghum is ground and most of it is divided into 6 Flaps, to obtain the main ingredients, the sorghum is subjected to high-temperature cooking.

[0029] (2) Mixing koji: After cooling the cooked sorghum, mix it with Daqu according to the mass ratio of sorghum and water of 1:0.63 to obtain the fermentation raw material.

[0030] (3) Saccharification and alcoholic fermentation: Put the fermented raw materials into a large fermentation vat for fer...

Embodiment 2

[0036] Embodiment 2 A kind of method utilizing steam explosion process to process vinegar auxiliary material to brew aged mature vinegar

[0037] A method for brewing old mature vinegar by processing vinegar auxiliary materials with a steam explosion process comprises the following steps:

[0038] (1) Raw material processing: put the bran into a steam explosion tank for steam explosion, the medium is water vapor, the pressure is 1.0Mpa, the temperature is 160°C, and the maintenance time is 10min to obtain auxiliary materials; the sorghum is ground and most of them are divided into 7 Flaps, to obtain the main ingredients, the sorghum is subjected to high-temperature cooking.

[0039] (2) Mixing koji: After cooling the cooked sorghum, mix it with Daqu according to the mass ratio of sorghum and water of 1:0.64 to obtain the fermentation raw material.

[0040] (3) Saccharification and alcoholic fermentation: put the fermented raw materials into a fermenting vat, rake twice a day ...

Embodiment 3

[0046] Embodiment 3 A kind of method of utilizing steam explosion process to process vinegar auxiliary material to brew aged mature vinegar

[0047] A method for brewing old mature vinegar by processing vinegar auxiliary materials with a steam explosion process, comprising the following steps:

[0048] (1) Raw material processing: put the bran into a steam explosion tank for steam explosion, the medium is water vapor, the pressure is 1.5Mpa, the temperature is 200°C, and the maintenance time is 15min to obtain auxiliary materials; the sorghum is ground to make most of it into 8 petals, get the main ingredient. The sorghum is steamed at high temperature.

[0049] (2) Mixing koji: After cooling the boiled sorghum, mix it with Daqu according to the mass ratio of sorghum and water of 1:0.65 to obtain the fermentation raw material.

[0050] (3) Saccharification and alcoholic fermentation: put the fermented raw materials into a fermenting vat, rake twice a day for the first 3 days...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com