Lime-based molten iron desulfurizer and preparation method thereof

A technology of molten iron desulfurization and lime, applied in the field of desulfurization outside the furnace, can solve the problems of erosion of refractory materials, polluted air, circulating water, high fluorine content of desulfurization slag, and achieve the effect of reducing desulfurization cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

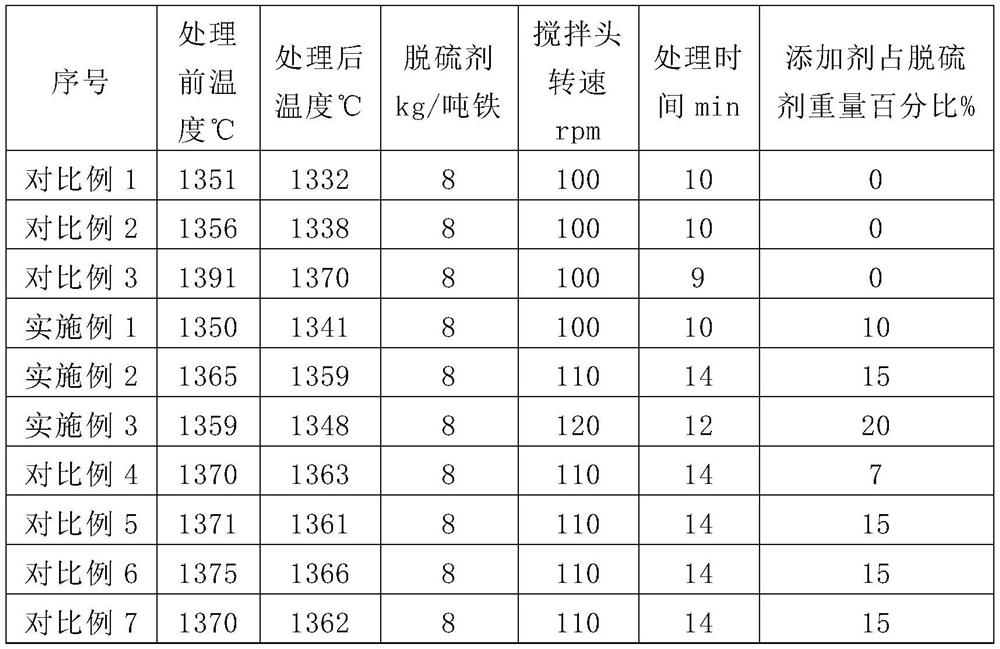

Embodiment 1

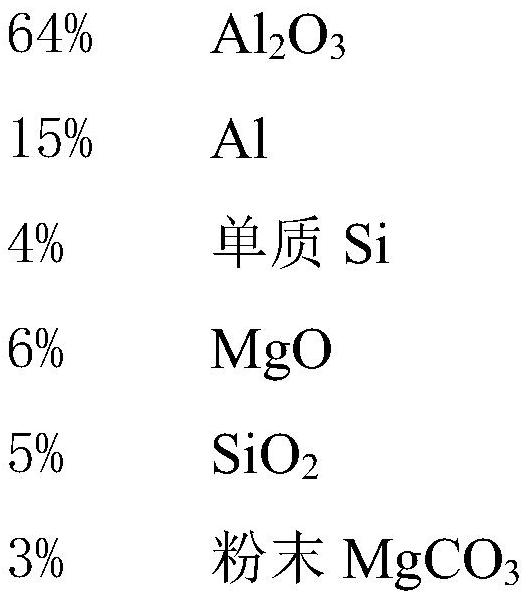

[0052] A lime-based molten iron desulfurizer, comprising 90% lime and 10% desulfurization additive by weight percentage, wherein the desulfurization additive utilizes at least metal Al, elemental Si, Al 2 o 3 The by-products of the aluminum industry are used as raw materials, which are prepared by grinding, grading, particle size adjustment, and adding corresponding raw materials according to their composition limits. The desulfurization additives include by weight percentage:

[0053]

[0054] CaO 87%, MgO 1.9%, SiO in lime 2 1.6%, S 0.046%, loss on ignition ≤5.0%. The activity of lime is 285 under the conditions of 4mol / ml 40±1°C and 10min. The particle size of lime is 0.64mm.

[0055] Al and simple Si are powdery materials fired at high temperature, with a particle size of 2mm. 2 o 3 , MgO and SiO 2 The particle size is 80 mesh, and it is also a material that has been fired at high temperature. The water content of the desulfurization additive is 0.38%. The carb...

Embodiment 2

[0057] The lime-based molten iron desulfurizer of this embodiment is different from that of Example 1 in that it includes 85% lime and 15% desulfurization additive by weight percentage and the powder MgCO in the desulfurization additive 3 The content of is 4%, and the carbonate particle size is 0.4mm, and all the other are with embodiment 1.

Embodiment 3

[0059] The lime-based molten iron desulfurizer of this embodiment is different from that of Example 1 in that it includes 80% lime and 20% desulfurization additive by weight percentage and the powder MgCO in the desulfurization additive 3 The content of is 5%, and all the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com