Planetary sample table capable of realizing automatic turning

A technology of automatic turning and sample stage, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problem that it is difficult to ensure the uniformity and symmetry of the film layers on the two surfaces of the substrate, and achieve heating Uniform, easy to arrange and set up effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

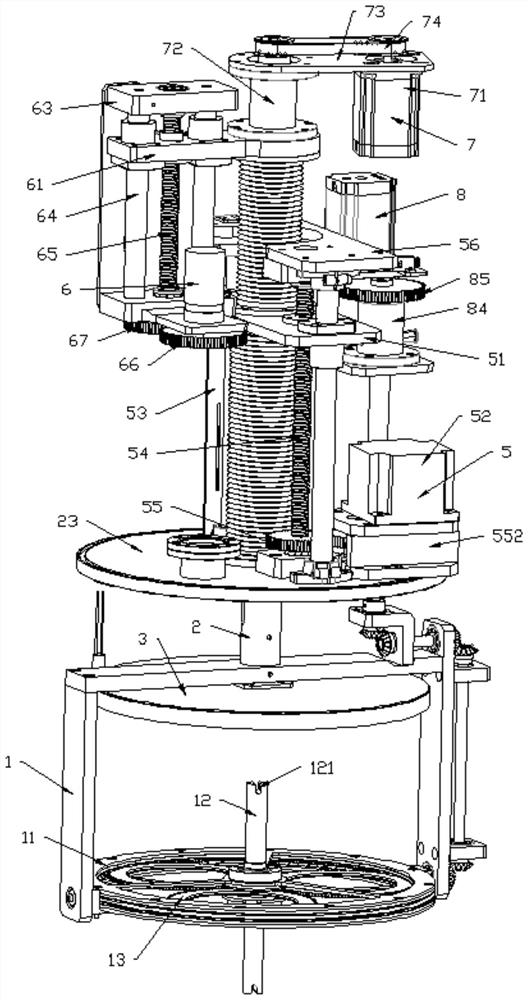

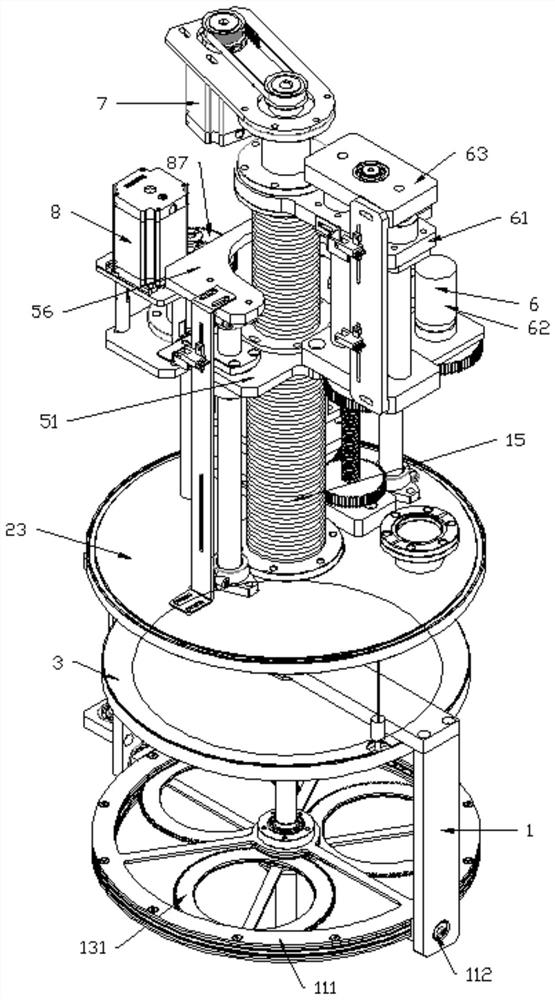

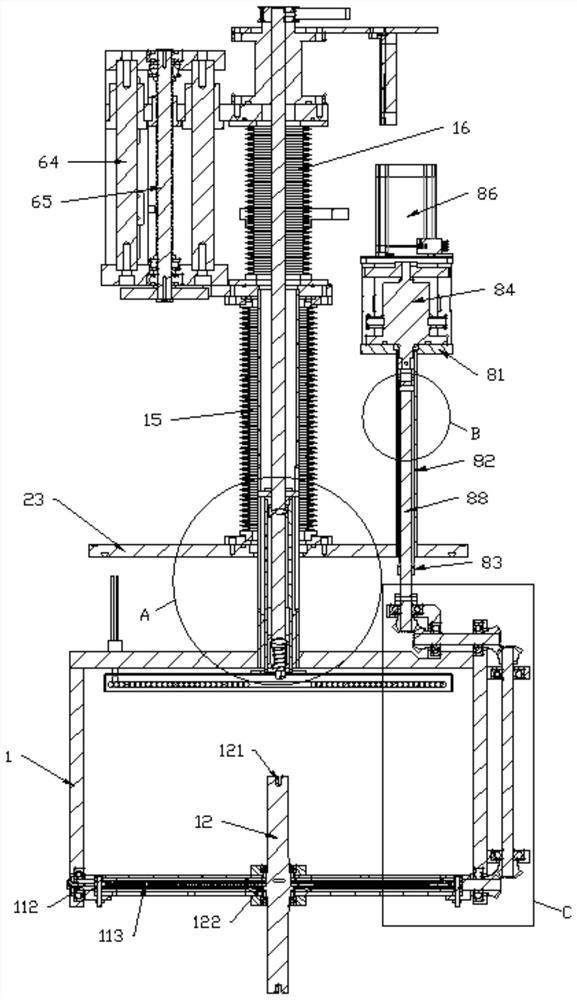

[0026] refer to Figure 1 to Figure 9As shown, a planetary sample stage that realizes automatic flipping in this embodiment includes a support 1, and a heating area 11 is arranged in the support 1. The heating area 11 includes a central rotating shaft 12 and several heating parts 13, and the substrate is placed on On the heating part 13, U-shaped grooves 121 are opened at both ends of the central rotating shaft 12, and a through hole 14 is opened on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com