Composite light body insulating glass with two pieces of glass and three cavities and manufacturing method thereof

A technology of hollow glass and production method, which is applied in parallel glass structures, building structures, building components, etc., can solve the problems of easy oxidation of coated glass, loss of heat insulation and energy saving effect, failure to reach mass production scale, etc. Energy saving and safety, improve impact toughness and surface finish, improve the effect of flame retardant grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

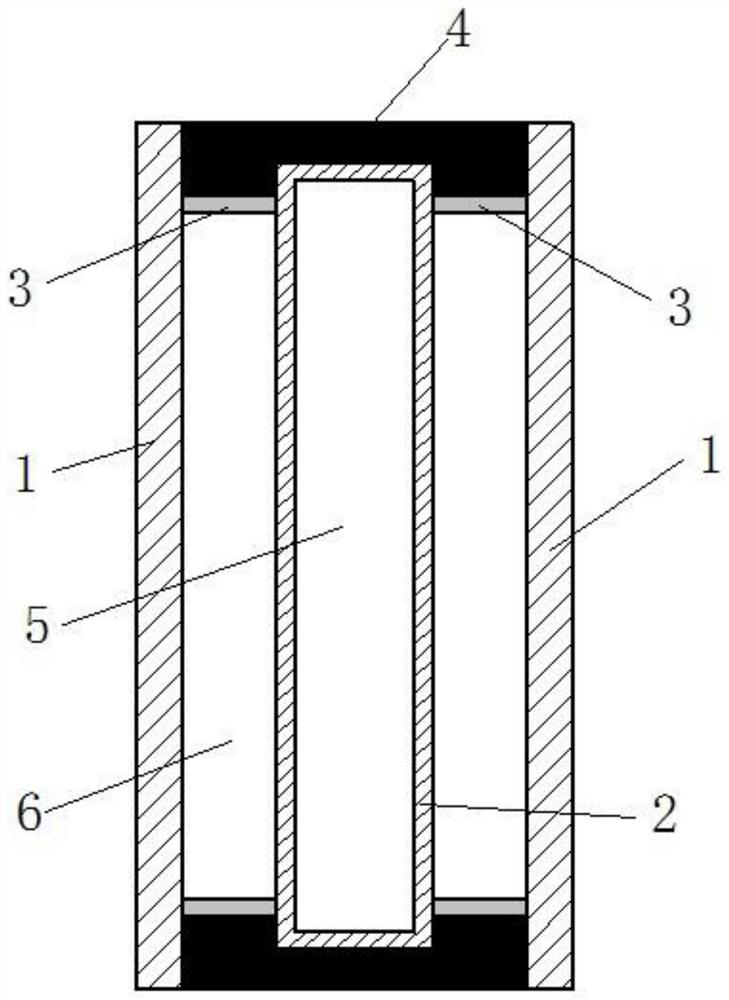

[0031] like figure 1 As shown, the two-glass three-cavity composite lightweight insulating glass of the present invention includes two pieces of glass 1, warm edge spacer 3 and structural sealant 4, and also includes polycarbonate formed integrally with a hollow cavity 5 The spacer 2, the hollow cavity 5 is filled with inert gas; the polycarbonate spacer 2 is placed between two pieces of glass 1; the two sides of the polycarbonate spacer 2 and the corresponding side glass 1 are along the A warm edge spacer 3 is arranged in the circumferential direction, so that an air interlayer 6 is formed between the two sides of the polycarbonate spacer 2 and the glass 1, and the air interlayer 6 is filled with a molecular sieve desiccant; the warm edge spacer 3 and the polycarbonate spacer 2 The outer two layers of glass 1 are sealed by structural sealant 4 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com