Ternary material precursor with nickel element in gradient distribution, and preparation method and application thereof

A ternary material, gradient distribution technology, applied in the field of materials, can solve the problem of the gradual disappearance of element gradient distribution, inconspicuousness, and inability to control the gradient distribution well, achieving good cycle stability, excellent rate performance, and safety performance. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

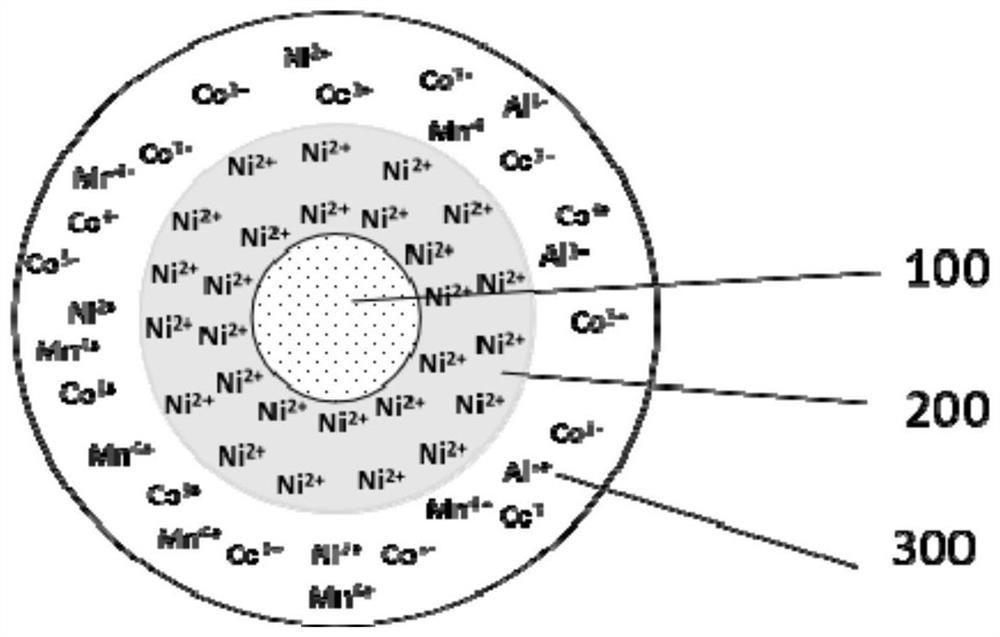

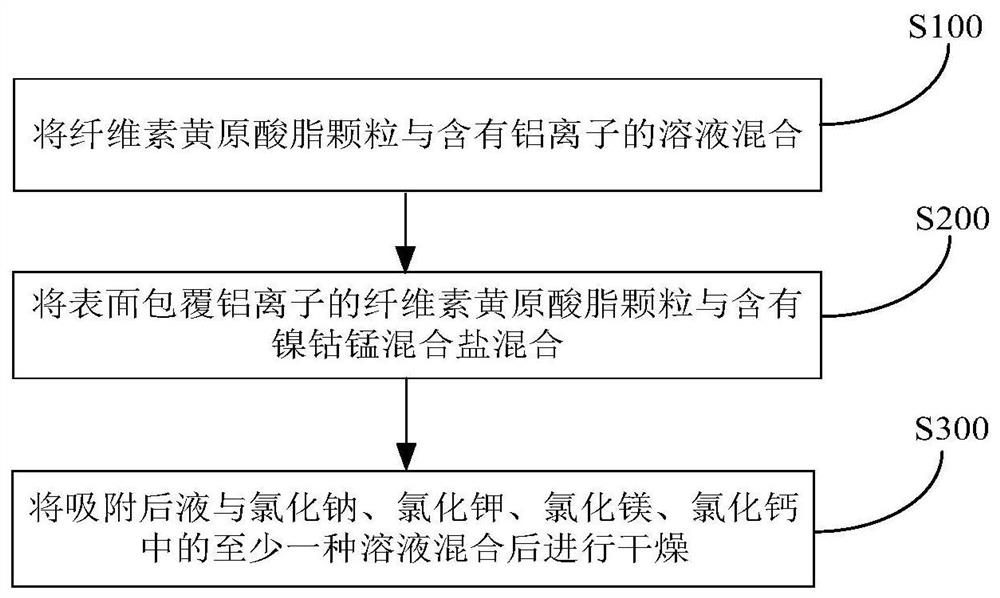

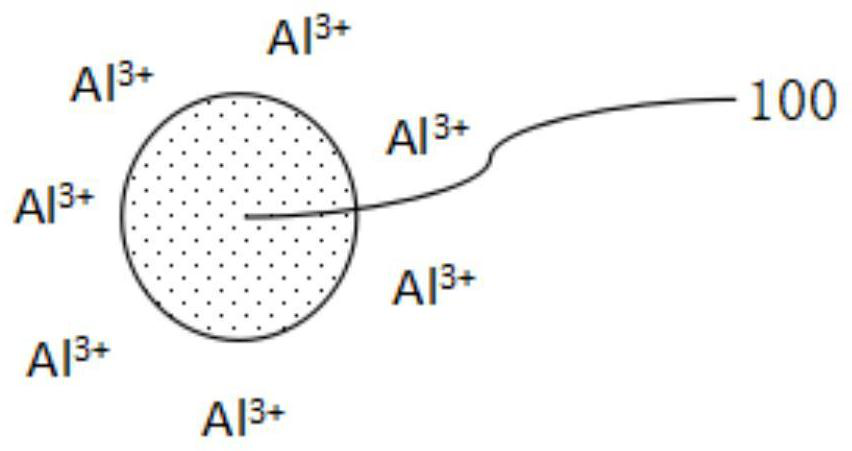

[0061] According to the method for preparing a ternary material precursor with a gradient distribution of nickel elements according to an embodiment of the present invention, by mixing cellulose xanthate particles with a solution containing aluminum ions, the aluminum ions are coated on the surface of the cellulose xanthate particles On the surface, the cellulose xanthate particles coated with aluminum ions are obtained. Add mixed salt containing nickel, cobalt and manganese at this time, because the surface of cellulose xanthate particles contains positively charged aluminum ions, thus nickel, cobalt and manganese ions will gather with cellulose xanthate as the center, because cellulose xanthate The lipid has a strong adsorption effect on nickel ions, so that the nickel ions in the nickel-cobalt-manganese salt gather at the periphery of the cellulose xanthate particles in the inner core, and along the center away from the inner core, the concentration of nickel ions in the sub...

Embodiment 1

[0069] The method for preparing the ternary material with nickel element gradient distribution comprises the following steps:

[0070] (1) Dissolve the cellulose xanthate powder in the aqueous solution containing aluminum ions and mix evenly (the ratio of cellulose xanthate and the aqueous solution containing aluminum ions is 30g: 700mL, and the concentration of the aqueous solution containing aluminum ions 8wt%), the solution was dried in an inert gas environment, and the resulting precipitate was pulverized for nano-processing, and the particle size of the cellulose xanthate particles after nano-processing was 60nm;

[0071] (2) Add a mixed solution of nickel-cobalt-manganese salt and ammonia water to the particles of nano-sized cellulose xanthate whose surface is coated with aluminum ions obtained in step (1) and mix evenly, and react for 12 to 15 hours, wherein the surface is coated with aluminum ions The mass ratio of nanoscale cellulose xanthate particles to the mixed sa...

Embodiment 2

[0075] The method for preparing the ternary material with nickel element gradient distribution comprises the following steps:

[0076] (1) Dissolve the cellulose xanthate powder in the aqueous solution containing aluminum ions and mix evenly (the ratio of cellulose xanthate and the aqueous solution containing aluminum ions is 40g: 700ml, and the concentration of the aqueous solution containing aluminum ions 8wt%), the solution is dried in an inert gas environment, and the resulting precipitate is pulverized for nano-processing, and the particle size of the cellulose xanthate particles after nano-processing is 50nm;

[0077] (2) Add a mixed solution of nickel-cobalt-manganese salt and ammonia water to the particles of nano-sized cellulose xanthate whose surface is coated with aluminum ions obtained in step (1) and mix evenly, and react for 12 to 15 hours, wherein the surface is coated with aluminum ions The mass ratio of nanoscale cellulose xanthate particles to the mixed salt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com