Positive electrode material for lithium rechargeable battery, positive electrode for lithium rechargeable battery, comprising same, and lithium rechargeable battery

A lithium secondary battery and positive electrode material technology, applied in secondary batteries, lithium batteries, battery electrodes, etc., can solve the problems of active material structure collapse voltage, accelerated battery cell degradation, high irreversible capacity, etc., to reduce the amount of outgassing , Improved high-temperature life characteristics, high-capacity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

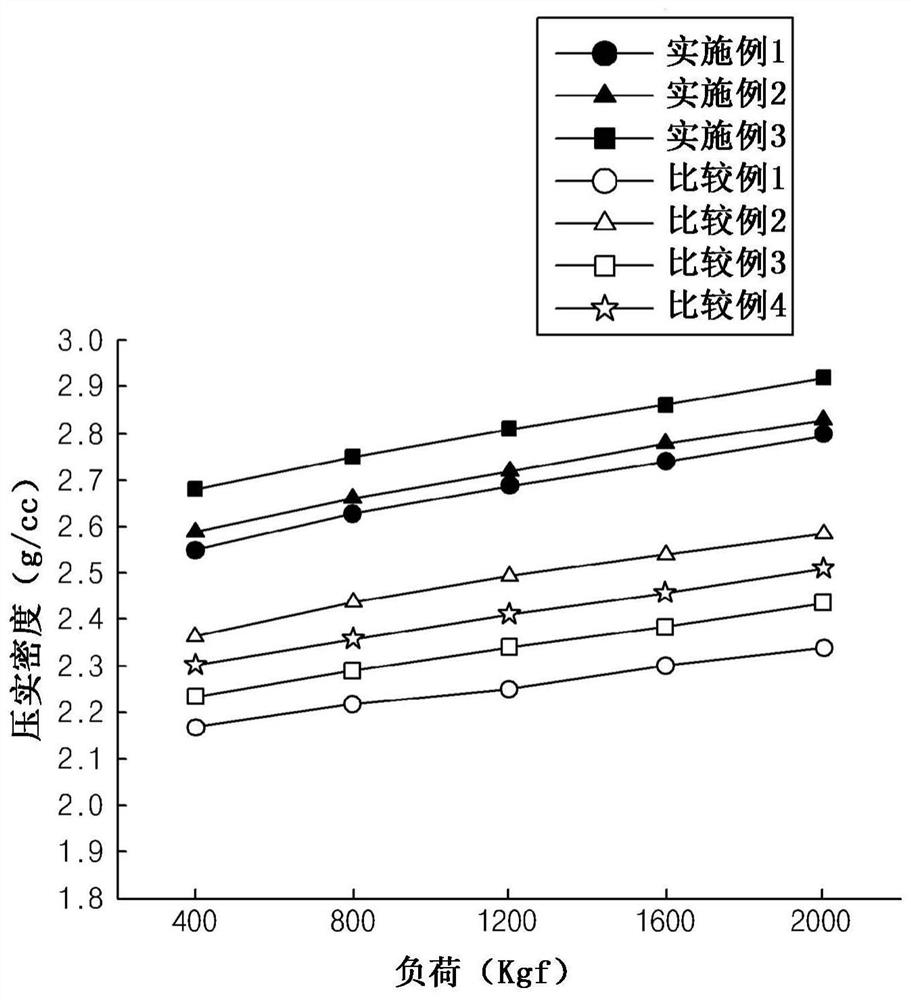

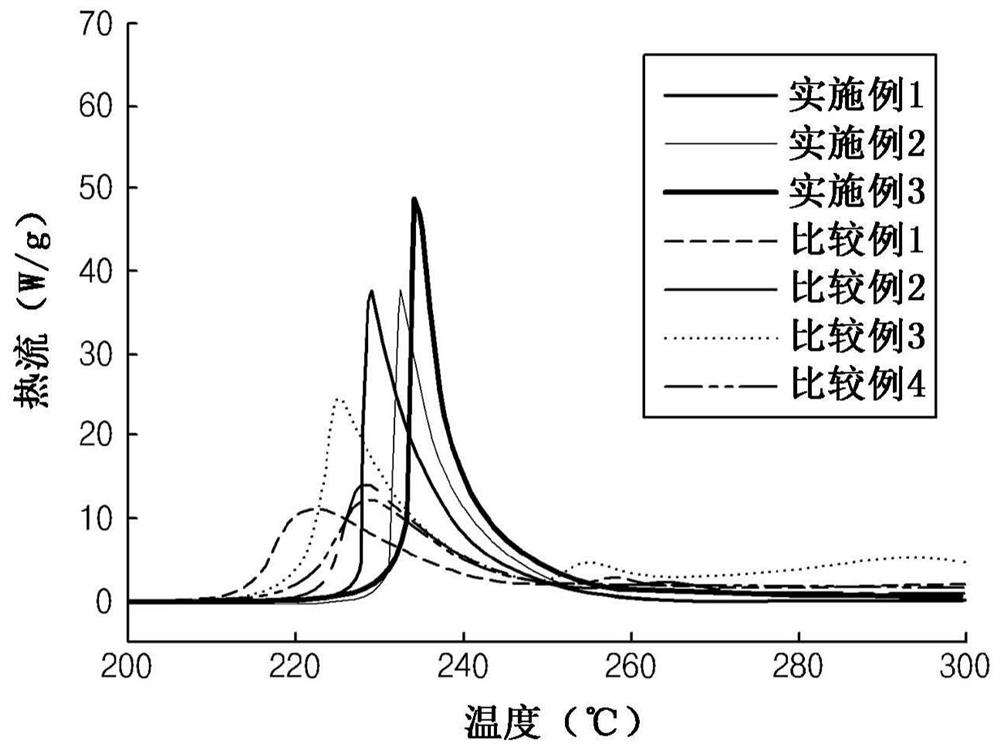

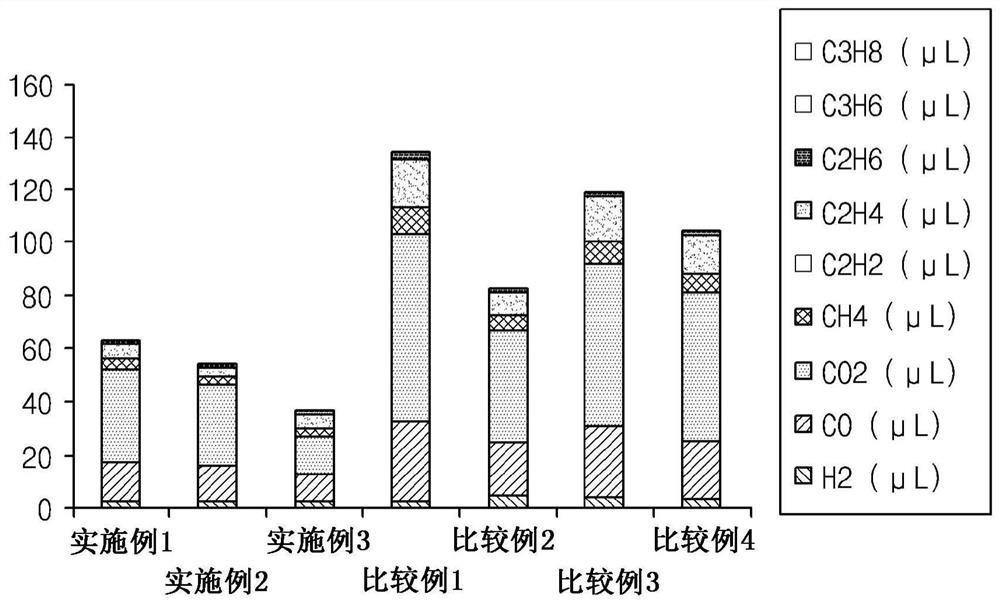

[0095] As the first positive electrode active material, the following lithium composite transition metal oxide was prepared in which the average particle diameter (D 50 ) is 11 μm, the molar ratio of Ni:Co:Mn is 33:25:42, (Li / Me) 1 is 1.1.

[0096] As the second positive electrode active material, the following lithium composite transition metal oxide was prepared in which the average particle diameter (D 50 ) is 5 μm, the molar ratio of Ni:Co:Mn is 60:20:20, (Li / Me) 2 is 1, the second positive electrode active material was over-sintered at 880° C. to obtain a crystal grain size of 200 nm and an average particle diameter of the primary particles (D 50) in the form of secondary particles of 1.8 μm. A positive electrode material for a lithium secondary battery was prepared by mixing the first positive electrode active material and the second positive electrode active material in a weight ratio of 70:30.

Embodiment 2

[0098] A positive electrode material for a lithium secondary battery was prepared by the same method as described in Example 1, except that, as the second positive electrode active material, the average particle diameter (D 50 ) is 5 μm, the molar ratio of Ni:Co:Mn is 60:20:20, and (Li / Me) 2 A lithium composite transition metal oxide of 1, and the second positive electrode active material was over-sintered at 950° C. to obtain a crystal grain size of 250 nm and an average particle diameter of the primary particles (D 50 ) in the form of secondary particles of 0.6 μm.

Embodiment 3

[0100] A positive electrode material for a lithium secondary battery was prepared by the same method as described in Example 1, except that, as the first positive electrode active material, the average particle diameter (D 50 ) is 11 μm, the molar ratio of Ni:Co:Mn is 28:22:50, and (Li / Me) 1 Lithium composite transition metal oxide of 1.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com