Tool for alignment outside machine tool during machining of FMS architecture

A machine tool and frame technology, applied to metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of insufficient positioning accuracy, non-compliance, and inability to align, and achieve easy operation, easy disassembly, and practicality. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

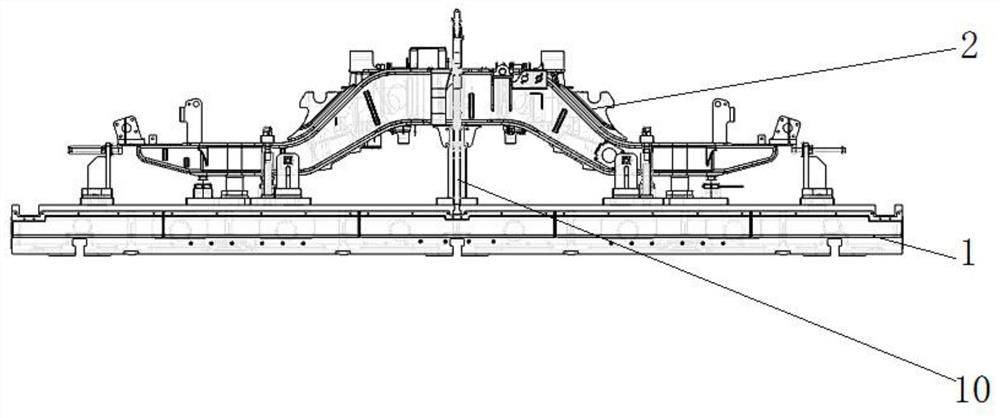

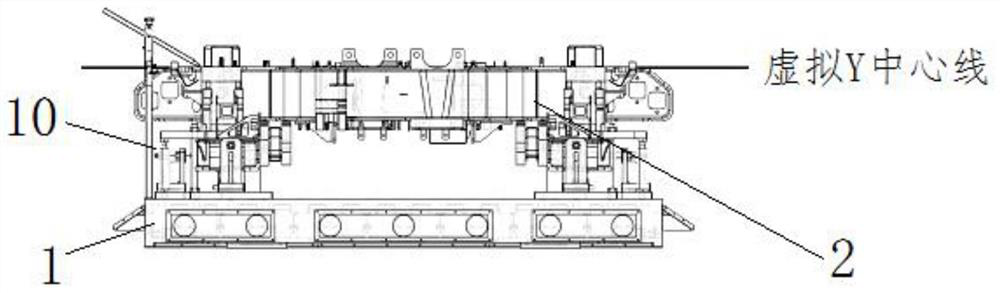

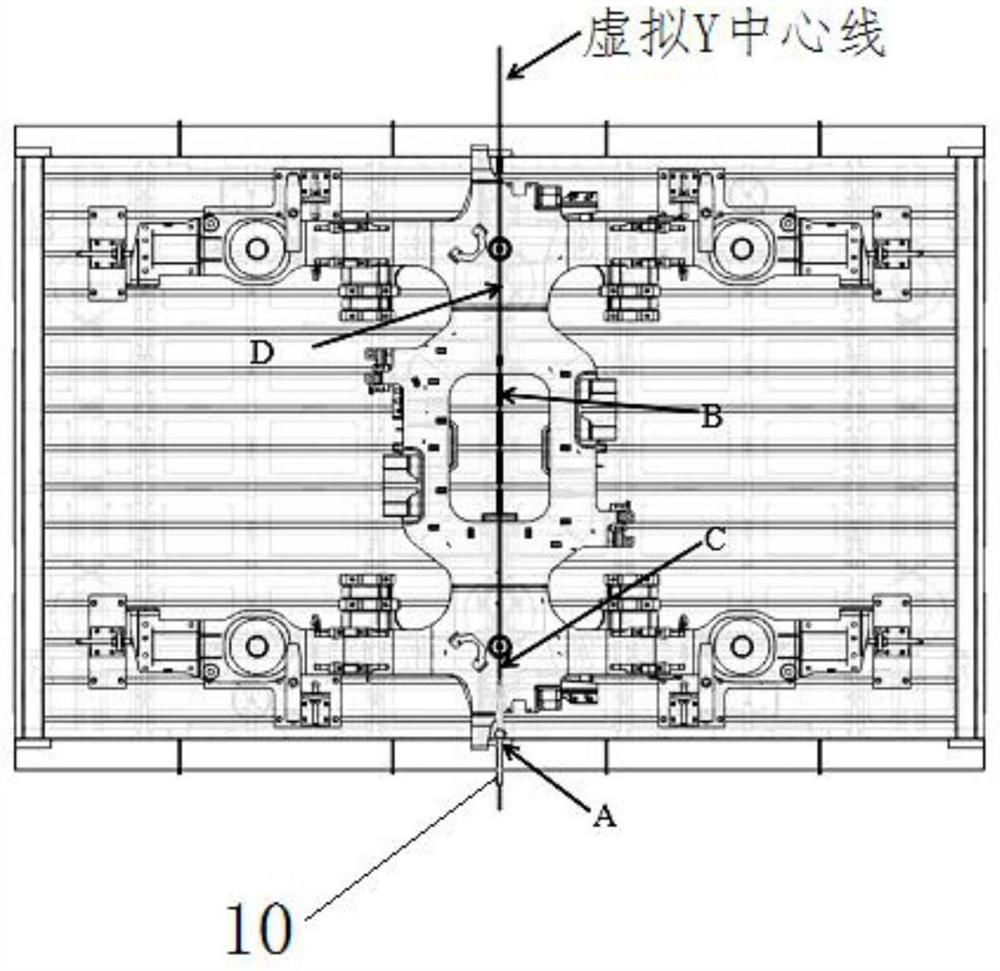

[0041] Such as Figure 1-6 As shown, the present embodiment provides a tool 10 for aligning outside the machine tool during FMS frame processing, which mainly includes a sliding seat 3 , a sleeve rod assembly 4 and a tip rod 5 . Wherein, the sliding seat 3 is used to be slidably installed in the T-shaped chute of the workbench 1, and the T-shaped chute extends along the virtual Y centerline in the figure; the sleeve rod assembly 4 is preferably mounted on the sliding seat 3 in a detachable manner, And the sleeve rod assembly 4 can realize height adjustment and circumferential rotation adjustment; the top rowing rod 5 is preferably installed on the top of the sleeve rod assembly 4 in a detachable manner, and the top rowing rod 5 can carry out tip telescopic adjustment relative to the sleeve rod assembly 4, Tip lifting adjustment and tip rotation adjustment, the adjustment range of the top rowing rod 5 is located in the plane where the top rowing rod 5 and the sleeve rod assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com