Method for directly electrolyzing indium strip liquor to extract metal indium

A technology of electrolytic extraction and back-extraction, which is applied in the fields of instruments, optics, photography, etc., can solve the problems of arsine poisoning, crude indium quality decline, and large difference, so as to improve quality, reduce overall cost, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described below with reference to specific examples. Those skilled in the art can understand that these examples are only used to illustrate the present invention and do not limit the scope of the present invention in any way.

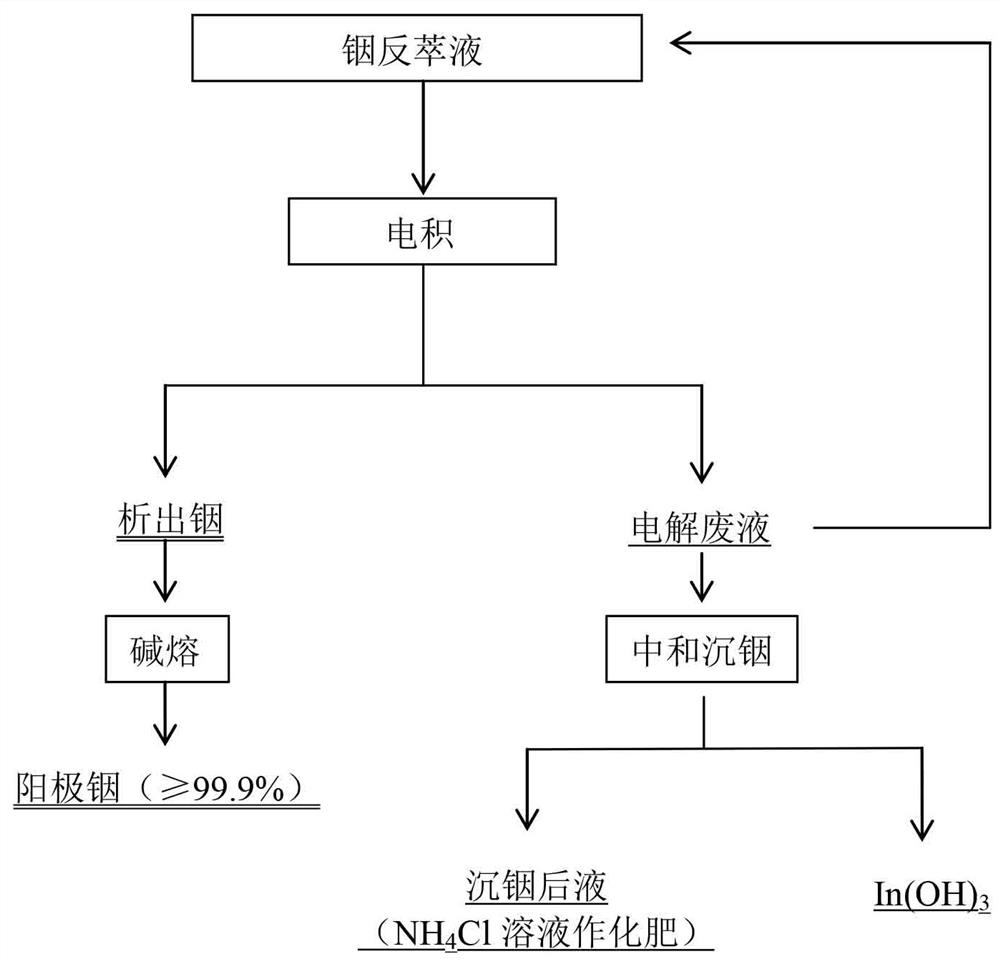

[0016] A method for directly electrolytically extracting metal indium from an indium stripping solution, such as figure 1 shown, including the following steps:

[0017] (1) Mix the purified indium stripping solution with part of the electrolytic waste solution to obtain a mixed solution;

[0018] (2) The purified indium stripping liquid solution or mixed solution continuously enters the electrolytic cell from the liquid inlet end of the electrolytic cell. The electrolytic cell uses a graphite plate with a thickness of 10-20mm as the anode plate, and a graphite plate with a thickness of 2-3mm The titanium plate is the cathode plate; direct current is applied to directly extract anode indium; the main reactions that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com