Stove burner

A technology for burners and stoves, which is applied in the direction of burners, gas fuel burners, combustion methods, etc. It can solve the problem that the secondary air is not fully preheated, and achieve the goals of not being easy to lose, improving combustion efficiency, and improving the energy-gathering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In the following, the present invention will be more clearly and completely described by way of embodiments in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

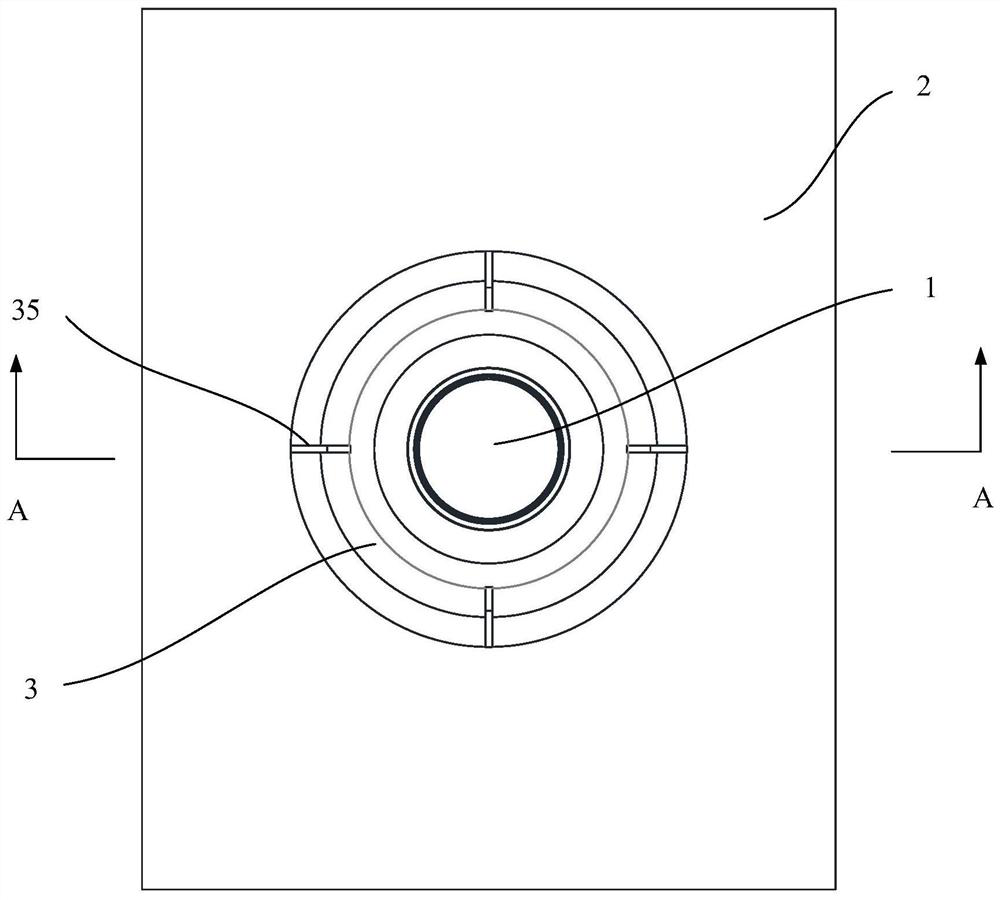

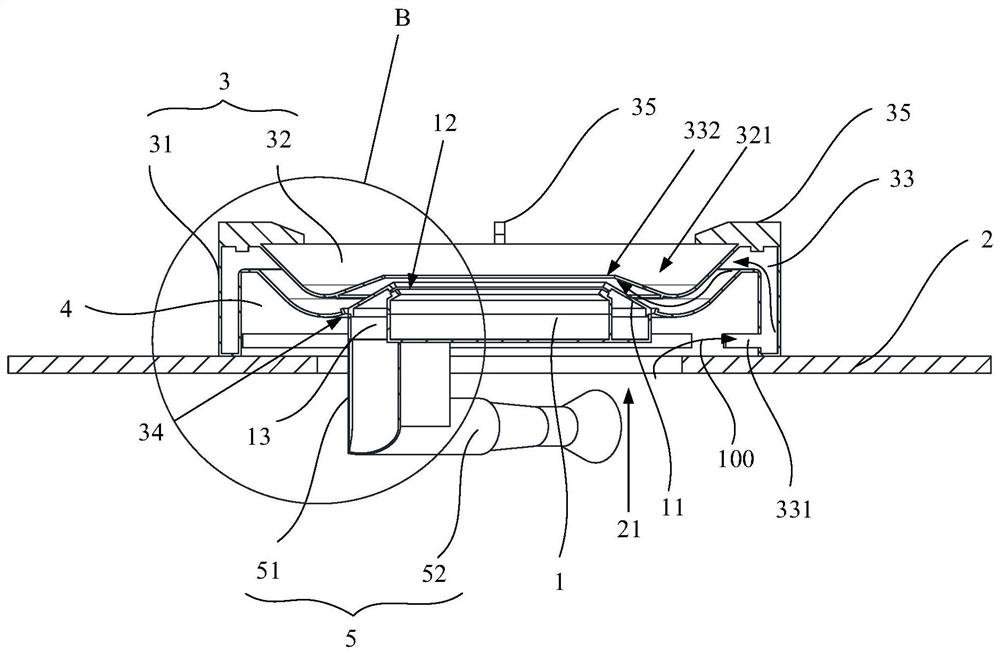

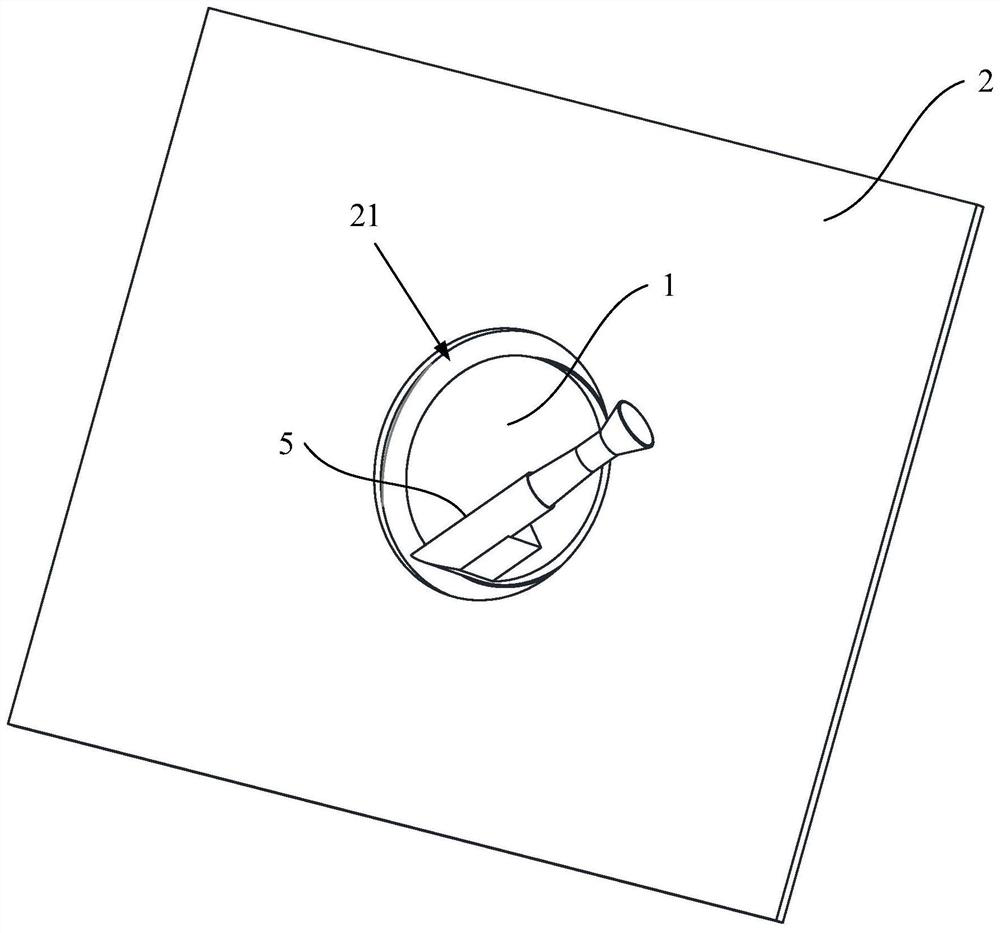

[0057] Such as Figure 1-Figure 5As shown, this embodiment discloses a cooker burner, which includes a fire cover 1 , a cooker panel 2 and an energy gathering cover 3 . The energy-gathering cover 3 is arranged on the cooker panel 2, the energy-gathering cover 3 surrounds the fire cover 1 and is covered on the peripheral side of the fire cover 1, and a heat exchange space 4 is formed between the fire cover 1, the cooker panel 2 and the energy-gathering cover 3. The entrance of the heat space 4 is located between the cooker panel 2 and the fire cover 1, and the inside of the energy gathering cover 3 is provided with a secondary air supply channel 33, which is connected with the heat exchange space 4, and the secondary air supply channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com