Multi-station safety belt overall performance testing device

A testing device and multi-station technology, which is applied in the measurement device, using stable tension/pressure to test the strength and strength characteristics of materials, etc., can solve the problems of high cost, inconvenient operation, inconvenient testing, etc., and achieve a simplified structure. , High test efficiency and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

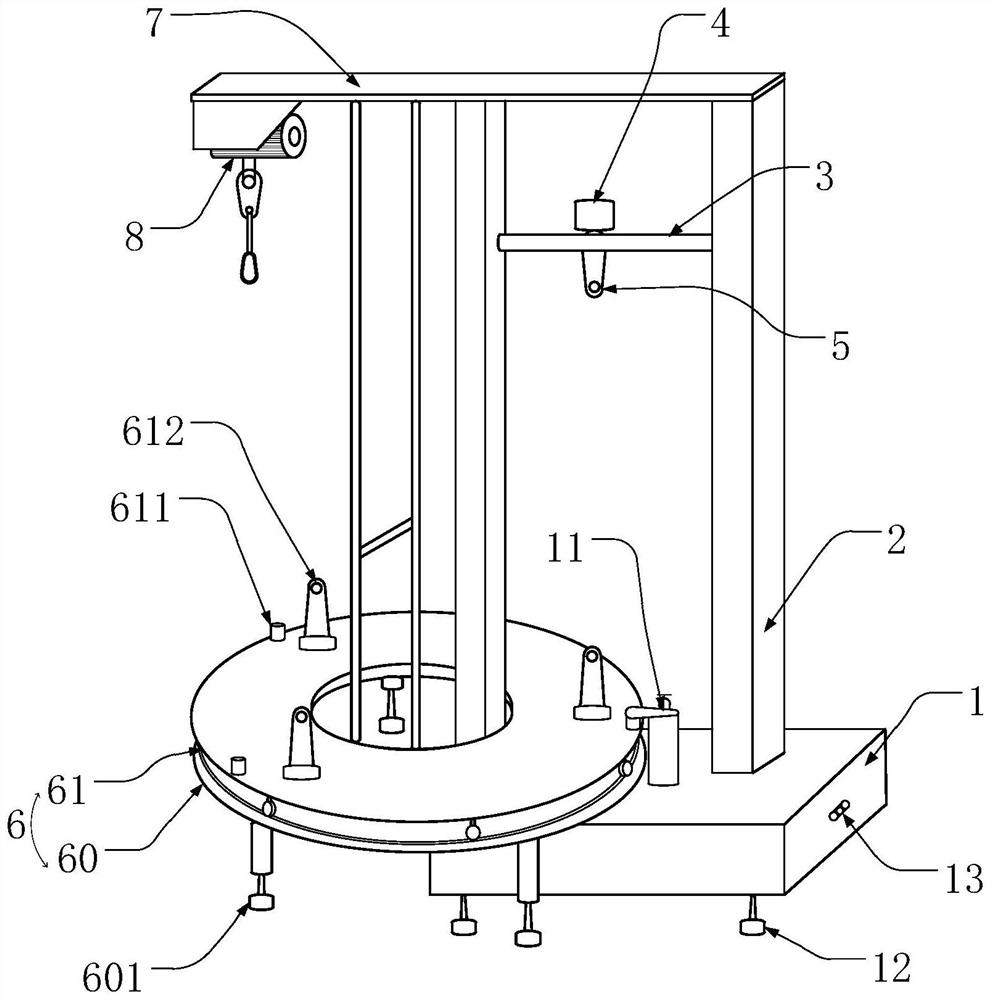

[0070] figure 1 It is a schematic diagram of the multi-station safety belt overall performance testing device disclosed in Example 1.

[0071] In Embodiment 1, the multi-station safety belt overall performance testing device includes a device chassis 1, which is a square structure, and the square structure device chassis 1 is the load-bearing structure of the test device, and is also a setting structure for some components. The motor is arranged inside the device chassis 1 with a square structure; the bottom of the device chassis 1 is provided with a first support foot 12, which is used to place the device chassis 1 stably and smoothly;

[0072] The device column 2 is set and fixed on the device chassis 1. The two device columns 2 are arranged parallel to each other and spaced apart, perpendicular to the device chassis 1. The two device columns 2 form a pillar for installing the stretching rod 3. The device column 2 is equipped with precision Ball screw pair;

[0073] The tw...

Embodiment 2

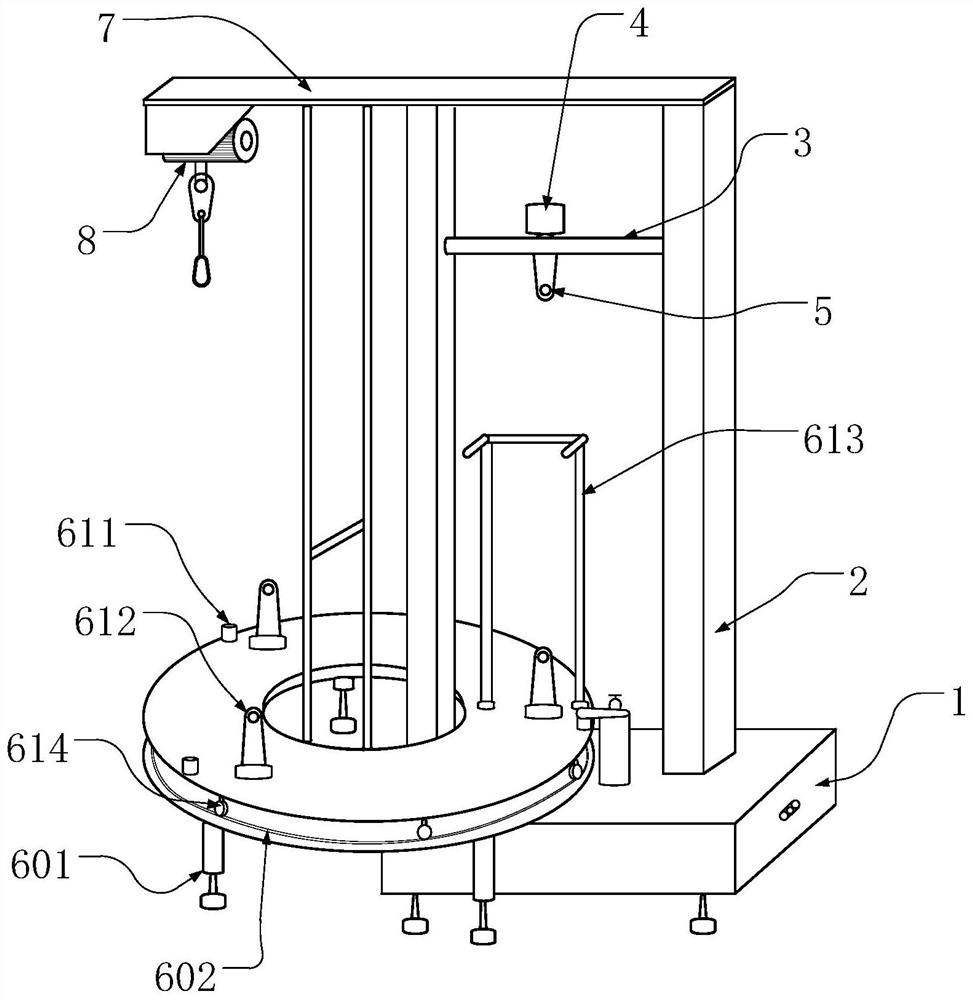

[0088] Schematic diagram of the multi-station safety belt overall performance testing device disclosed in Embodiment 2.

[0089] In Embodiment 2, the multi-station safety belt overall performance testing device includes a device chassis 1, which is a square structure, and the square structure device chassis 1 is the load-bearing structure of the test device, and is also a setting structure for some components. The motor is arranged inside the device chassis 1 with a square structure; the bottom of the device chassis 1 is provided with a first support foot 12, which is used to place the device chassis 1 stably and smoothly;

[0090] The device column 2 is set and fixed on the device chassis 1. The two device columns 2 are arranged parallel to each other and spaced apart, perpendicular to the device chassis 1. The two device columns 2 form a pillar for installing the stretching rod 3. The device column 2 is equipped with precision Ball screw pair;

[0091] The two ends of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com