Development method of epoxy resin impregnated glass fiber direct-current sleeve

A glass fiber and epoxy resin technology, applied in insulators, electrical components, insulators, etc., can solve the problem of affecting the initial curing process of the casing core, affecting the space charge accumulation effect on the interface of the casing medium, and affecting the field strength distribution of the casing. and other problems, to achieve the effect of reducing the difficulty of the winding process, rational distribution, and ensuring reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

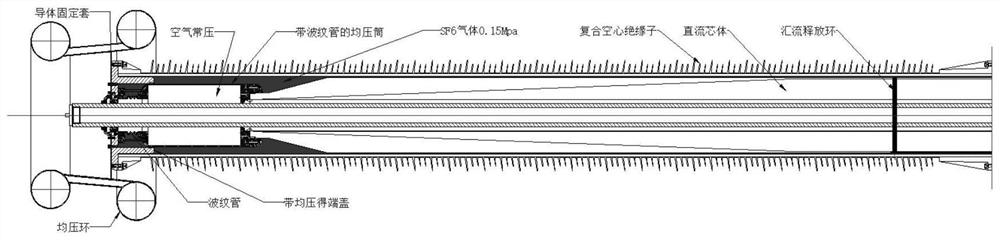

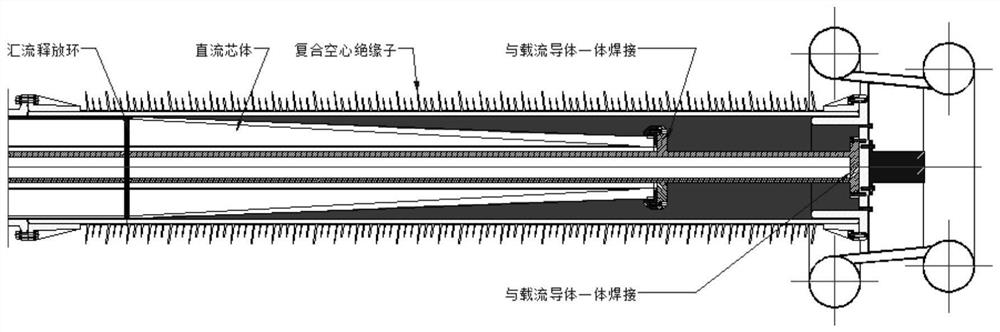

[0027] A method for developing an epoxy resin impregnated glass fiber DC bushing, comprising the following steps:

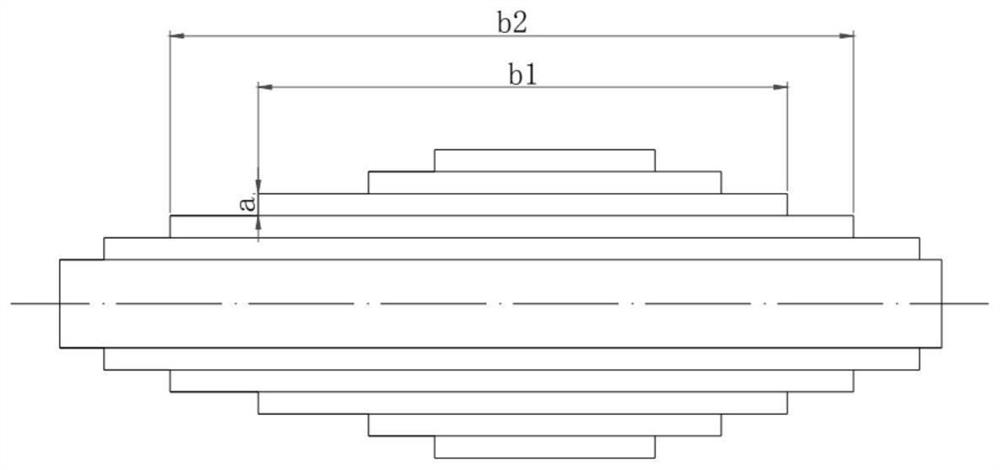

[0028] S1. Core winding, according to the length parameters of each layer of capacitive screen (resistive screen) designed according to the insulation requirements, the parameters of every two layers of capacitor thickness are equal to 2.5mm, and the winding machine program is set according to the casing design parameters, and the winding temperature is 90°C , during the winding process of the casing core, it is also gradually solidified;

[0029] S2. The core body is cured. After the core body is wound, it is sent to the oven, and a reasonable oven temperature and duration are set to ensure that the core body is completely cured;

[0030] S3. The cured core is machined according to the design drawings of the core. The feed rate for rough machining is 0.1 mm, and the feed rate for finishing is 0.02 mm to complete the mechanical processing of the core body;

[00...

Embodiment 2

[0035] A method for developing an epoxy resin impregnated glass fiber DC bushing, comprising the following steps:

[0036] S1. Core winding. According to the length parameters of each layer of capacitive screen (resistive screen) designed according to the insulation requirements, the parameter of 3mm is taken as the thickness of every two layers of capacitance is equal. Set the winding machine program according to the design parameters of the casing. During the winding process of the casing core, it is also gradually solidified;

[0037] S2. The core body is cured. After the core body is wound, it is sent to the oven, and a reasonable oven temperature and duration are set to ensure that the core body is completely cured;

[0038] S3. The cured core is machined according to the core design drawing. The rough machining feed is 0.2mm, and the finishing feed is 0.04mm to complete the core machining;

[0039] S4. Glue the core body and the flange, grind and clean the inner wall of...

Embodiment 3

[0043] A method for developing an epoxy resin impregnated glass fiber DC bushing, comprising the following steps:

[0044] S1. Core winding, the length parameters of each layer of capacitive screen (resistive screen) designed according to insulation requirements, the parameters of 3.5mm for every two layers of capacitor thickness are equal, and the winding machine program is set according to the casing design parameters, and the winding temperature is 100°C , during the winding process of the casing core, it is also gradually solidified;

[0045] S2. The core body is cured. After the core body is wound, it is sent to the oven, and a reasonable oven temperature and duration are set to ensure that the core body is completely cured;

[0046] S3. The cured core is machined according to the core design drawing. The rough machining feed is 0.3 mm, and the finishing feed is 0.06 mm to complete the core machining;

[0047] S4. Glue the core body and the flange, grind and clean the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com