Light fireproof composite limiting plate and production method thereof

A production method and technology of limiting plates, which are applied in the field of composite limiting plates, can solve problems such as damage to the plate body and poor fire resistance of composite limiting plates, and achieve the effects of preventing delamination and falling off, facilitating hot pressing production, and preventing further damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

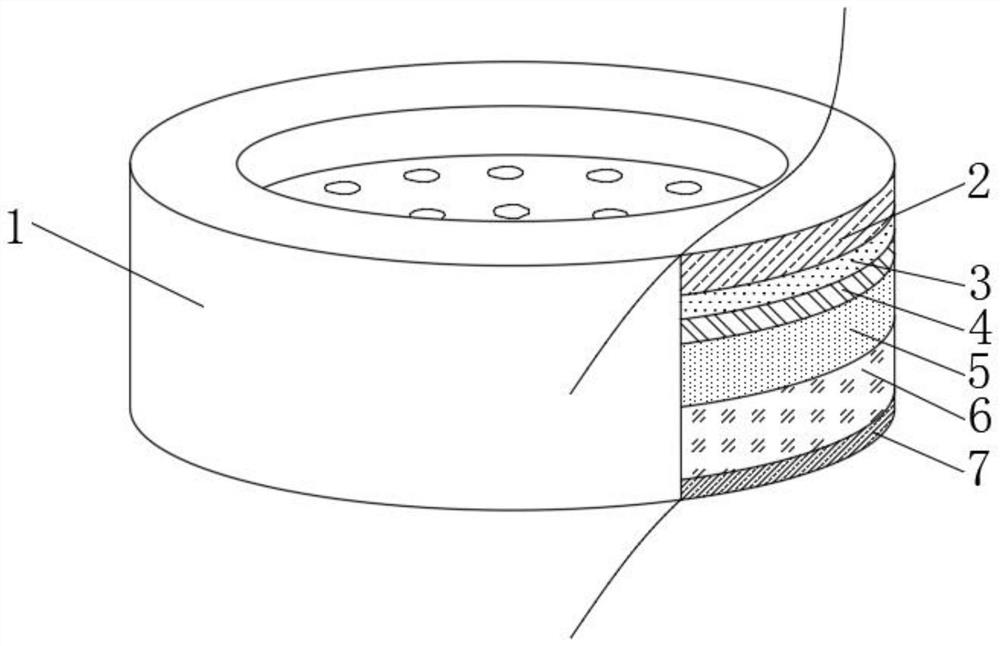

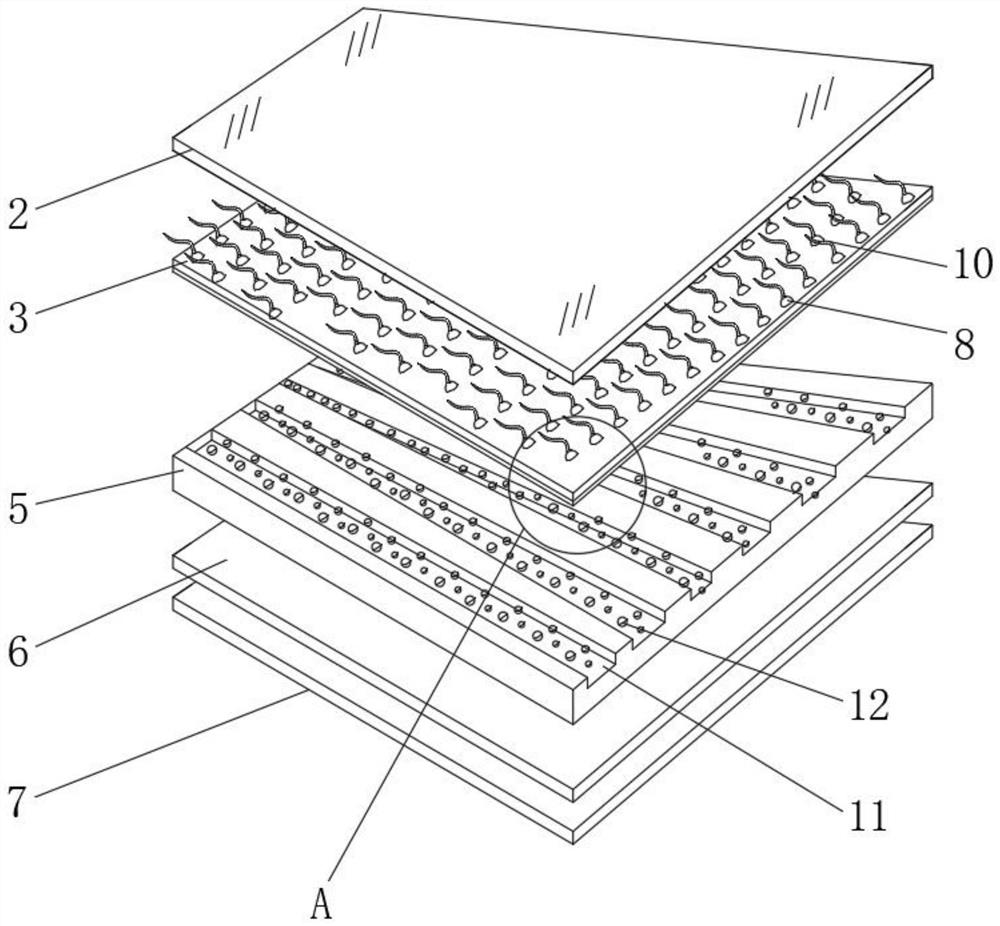

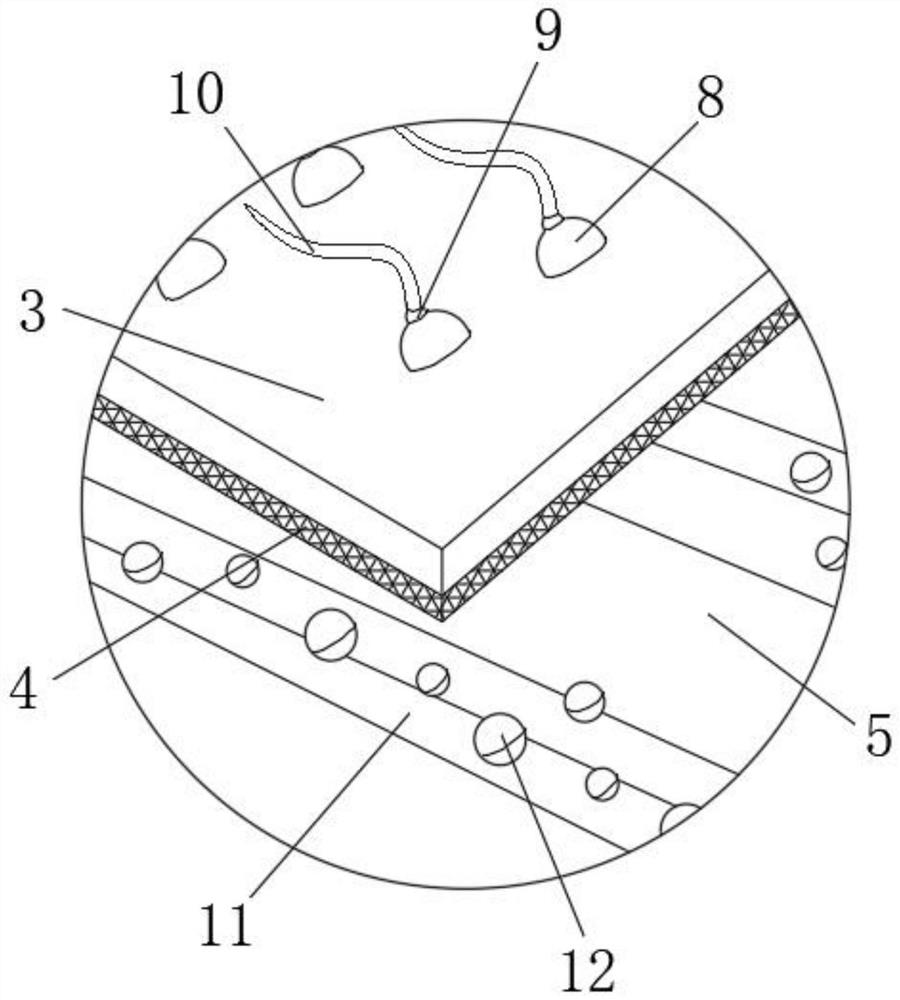

[0050] see Figure 1-7 , a light-weight refractory composite limiting plate and a production method thereof, comprising a limiting plate body 1, the outer surface of the limiting plate body 1 is provided with an outer layer 2, the lower side of the outer layer 2 is provided with an anti-stripping layer 3, and The lower surface of the delamination 3 is connected with an adhesive layer 4, the lower side of the adhesive layer 4 is provided with a fireproof layer 5, the lower side of the fireproof layer 5 is provided with a waterproof layer 6, and the lower surface of the waterproof layer 6 is connected with an inner surface layer 7 , the upper surface of the anti-detachment layer 3 is fixedly installed with an installation ball 8, the top of the installation ball 8 is fixedly installed with a connector 9, the top of the connector 9 is fixed with an intricate fiber 10, and the upper surface of the fireproof layer 5 is provided with a fireproof groove 11 , the inside of the firepro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com