Bionic flapping-wing micro air vehicle capable of realizing high control moment generation based on double-wing differential motion and steering engine gravity center change

A micro-aircraft and torque control technology, which is applied in the field of bionic flapping-wing micro-aircraft, can solve the problems of small control torque, single rectangular form of control force, and limited change range of angle of attack, so as to improve control torque, increase displacement range, and improve effective The effect of control torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation method of the present invention will be described in detail below in conjunction with the accompanying drawings.

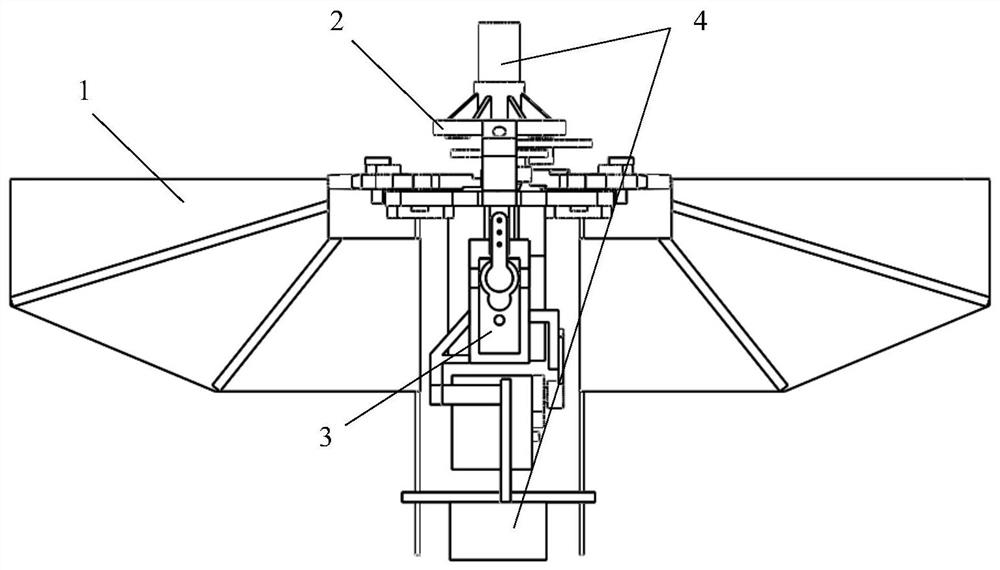

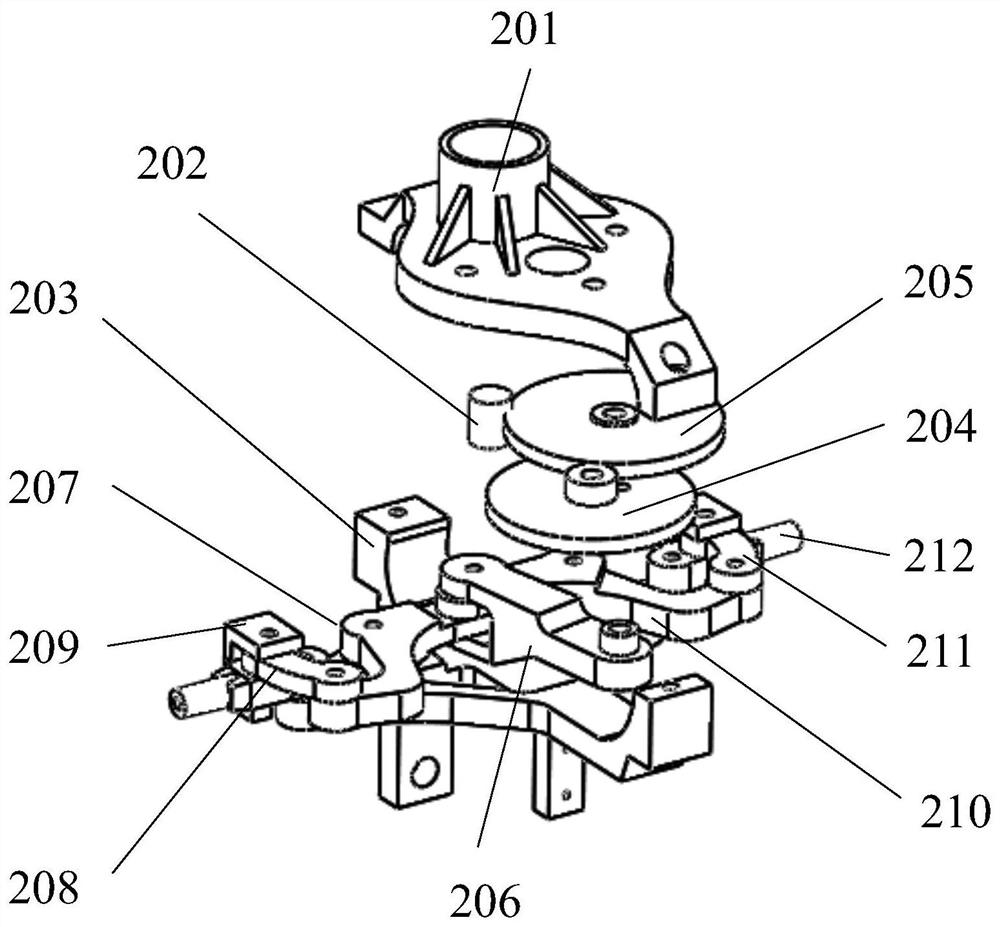

[0042] The bionic flapping-wing micro-aircraft that realizes the generation of high control moment based on the differential of the two wings and the change of the center of gravity of the steering gear includes a lift system 1 , a transmission system 2 , a control system 3 and a power system 4 .

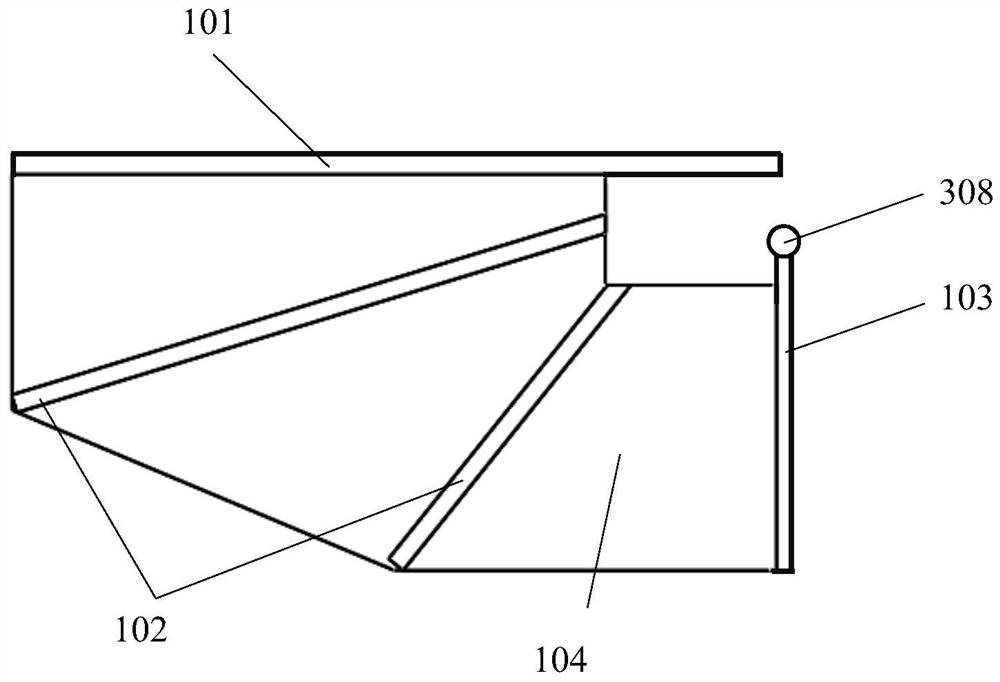

[0043] The lift system 1 is composed of left and right flapping wings, and each flapping wing is composed of a main beam 101 , a flexible beam 102 , a tension beam 103 and a membrane 104 . The wing membrane 104 is a flexible membrane made of polyimide material, and the front edge and the side edge of the wing membrane 104 are respectively wrapped into tubes and then fixed with an adhesive. The main beam 101 and the tension beam 103 pass through the tubular space formed by the front edge and the side edge of the wing membrane 104 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com