Novel gas stripping device

A new type of gas lift technology, applied in the field of new gas lift devices, can solve problems such as the optimization of liquid internal carriers, achieve good sewage treatment effects, and increase the frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

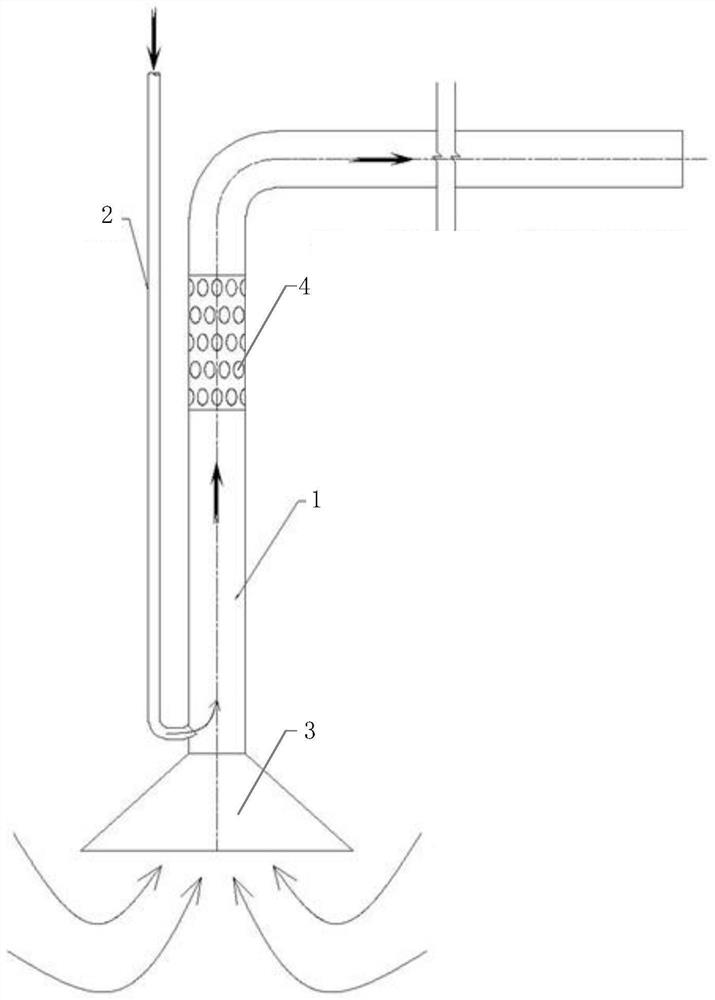

[0030] This embodiment provides a novel gas lift device, such as figure 1 As shown, the novel gas lift device includes a gas delivery pipe 2, a gas lift pipe 1, a liquid inlet pipe 3 and a friction member, the gas lift pipe 1 is in an inverted L shape, and the liquid inlet pipe 3 is connected to the gas lift pipe 1, the gas inlet of the gas delivery pipe 2 is used to charge gas, and the gas outlet is fluidly connected to the bottom of the stripping pipe 1 and is located above the liquid inlet pipe 3, and the friction member includes A plurality of friction protrusions 4 are evenly arranged on the inner wall of the stripping tube 1 .

[0031] The novel gas lift device of this embodiment utilizes the density difference of the liquid inside and outside the gas lift tube to lift the liquid. Specifically, when in use, the liquid inlet pipe 3 can be placed in the place where the carriers in the biochemical tank of the MBBR sewage treatment system are densely packed, and high-pressu...

Embodiment 2

[0034] Novel gas stripping device as described in embodiment 1, such as figure 1 As shown, the liquid inlet pipe 3 is trumpet-shaped, and the smaller end of the trumpet-shaped liquid inlet pipe 3 is connected to the stripping pipe 1;

[0035] The trumpet-shaped liquid inlet pipe 3 is integrally formed with the stripping pipe 1 .

[0036] The liquid inlet pipe 3 is in the shape of a trumpet, so that the compressed air and other gases transported here through the gas delivery pipe 2 can be quickly discharged into the liquid, and the gas-liquid mixture can also enter the stripping pipe 1 through the liquid inlet pipe 3 more quickly and start to be vaporized. to another location.

Embodiment 3

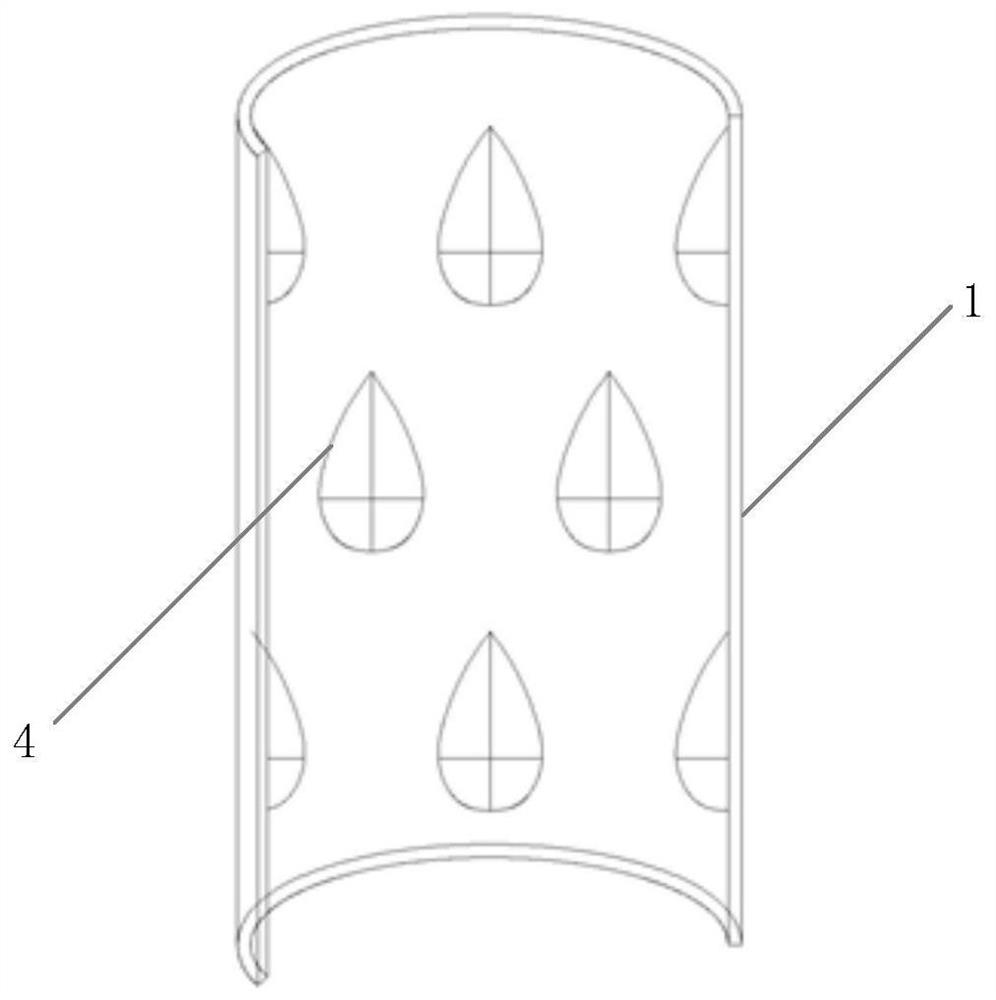

[0038] Novel gas stripping device as described in embodiment 1, such as Figure 2-4 As shown, the friction protrusions 4 are in the shape of water droplets and have a smooth surface. A plurality of friction protrusions 4 are arranged in parallel, and each water drop-shaped friction protrusion 4 is arranged with its tip pointing upward.

[0039] According to the Venturi theory, in this embodiment, the friction protrusion is designed as a three-dimensional polyhedral drop shape, which will generate a pressure difference when water and air flow, increase the disturbance of the water flow, and increase the contact and collision probability between the carrier and the friction protrusion in the water flow. At the same time, the air in the water flow is cut into fine bubbles, which can promote the dissolution of oxygen in water, provide more dissolved oxygen for the biofilm on the carrier, and a higher concentration of dissolved oxygen can promote the activity of microorganisms on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com