Method for trapping and removing benzopyrene in flue gas

A benzopyrene and flue gas technology, applied in the field of environmental protection flue gas treatment, can solve problems such as complex operation, high cost, and large resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a carbon factory, the flue gas from the carbon production process contained 15 μg / m of benzopyrene 3 , the local environmental protection department requires that its emission shall not exceed 2.5μg / m 3 , which is seriously exceeded. Because there is no mature technology for governance at present, the technology of this embodiment is used for experimentation. The exhaust gas temperature is 205°C, and the dust after cyclone dust removal is 30mg / m 3 , tar 50mg / m 3 .

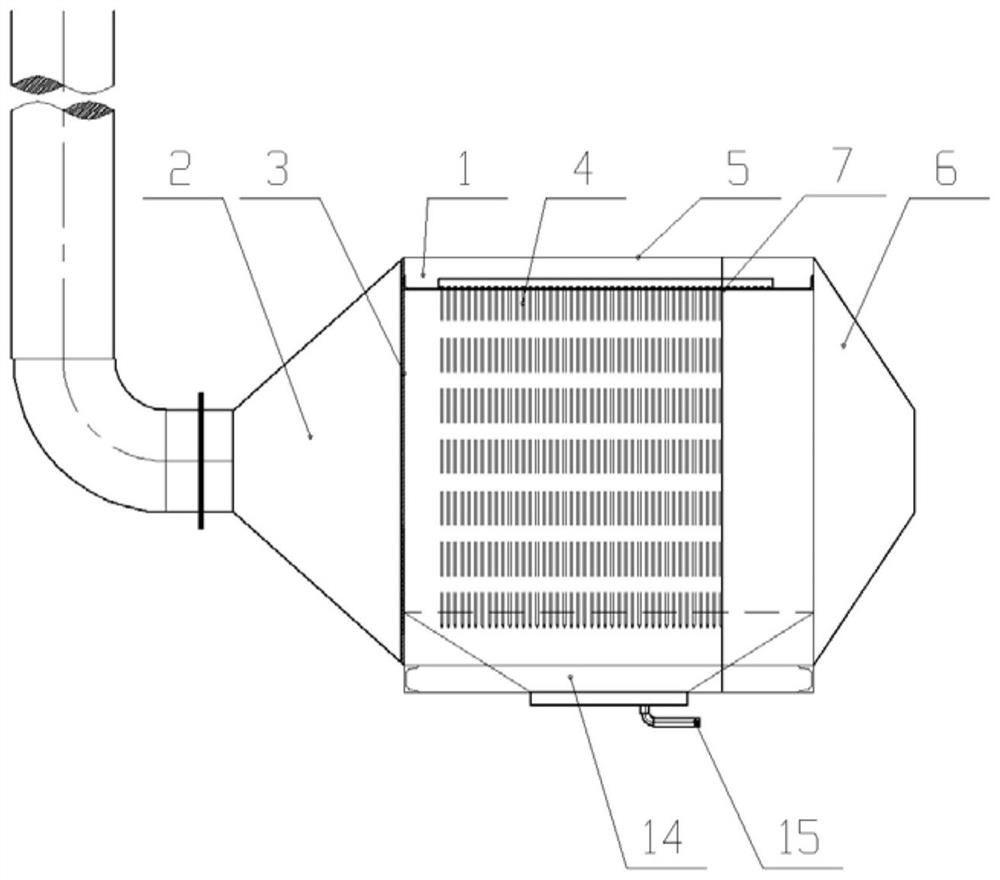

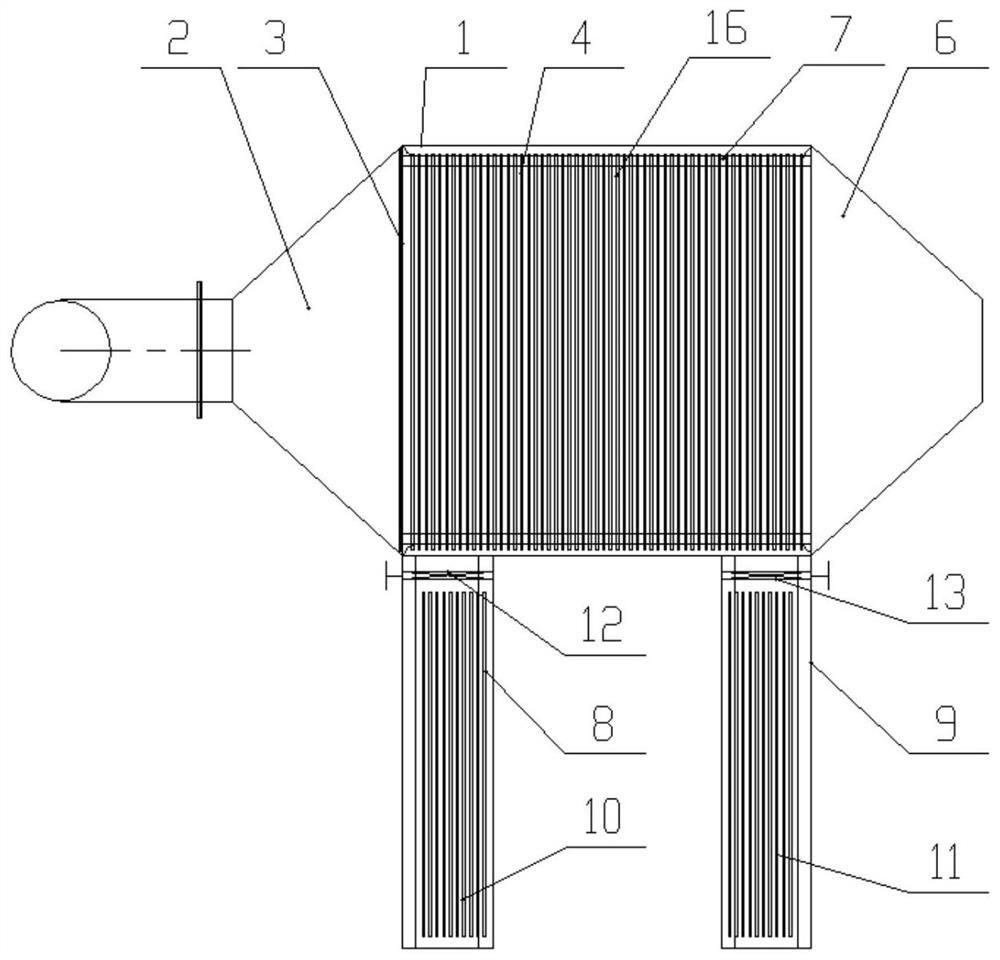

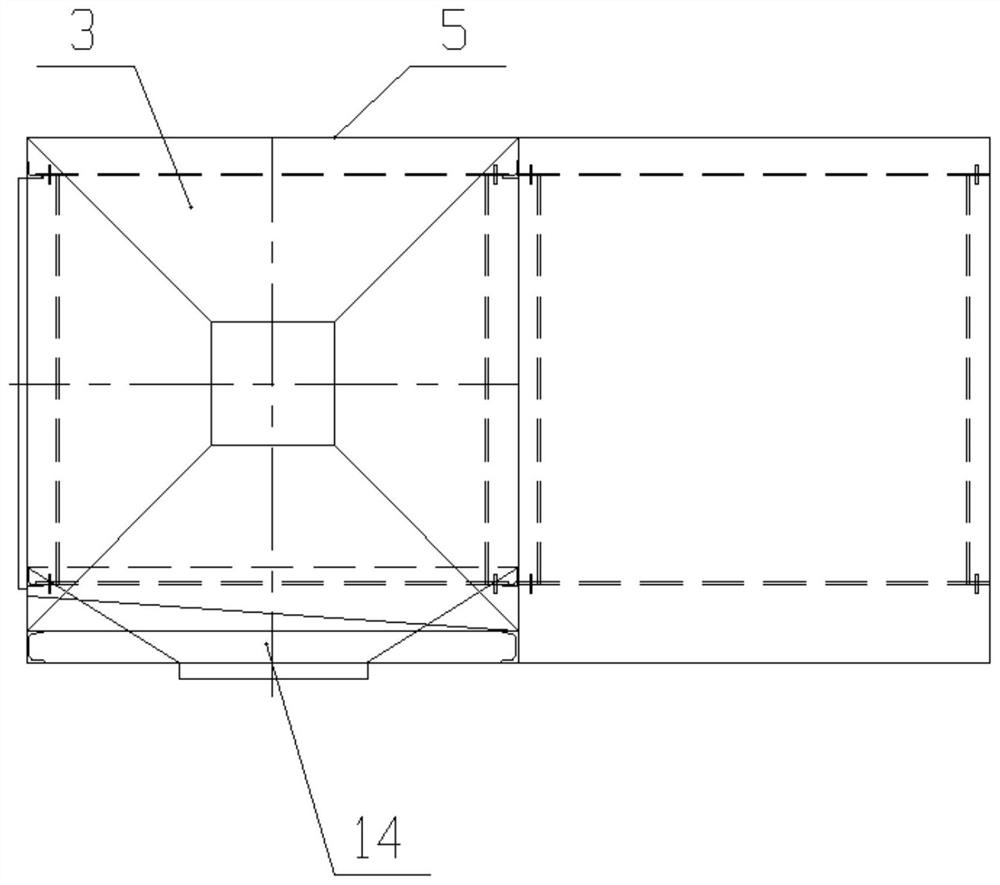

[0037] A device for trapping and removing benzopyrene in flue gas, the front view is as follows figure 1 As shown, the top view is as figure 2 As shown, the left view is as image 3 As shown, the schematic diagram of the trapping bundle structure is shown in Figure 4 As shown, the structure includes 1-housing, 2-flue gas inlet, 3-pressure equalizing plate, 4-capture chamber, 5-upper cover, 6-flue gas outlet, 7-leading groove, 8-removing section guide groove , 9-guide groove of the moving-in sect...

Embodiment 2

[0050] The flue gas volume of the roasting production line of a carbon factory is 6000Nm 3 / h, the exhaust gas temperature is 280°C, and the dust after the initial dust removal treatment is 35mg / m 3 , tar 100mg / m 3 , Benzopyrene 17μg / m 3 . All exceed local environmental protection requirements. Therefore, this case is adopted for governance.

[0051] A device for trapping and removing benzopyrene in flue gas, the front view is as follows figure 1 As shown, the top view is as figure 2 As shown, the left view is as image 3 As shown, the schematic diagram of the trapping bundle structure is shown in Figure 4 As shown, the structure includes 1-housing, 2-flue gas inlet, 3-pressure equalizing plate, 4-capture chamber, 5-upper cover, 6-flue gas outlet, 7-leading groove, 8-removing section guide groove , 9-guide groove of the moving-in section, 10-isostatic plenum of the moving-out section, 11-isostatic plenum of the moving-in section, 12-valve plate of the isostatic plenu...

Embodiment 3

[0067] Smoked chicken production line of a food processing factory, the maximum amount of smoke is 500Nm 3 / h, the exhaust gas temperature is 165°C, and the benzopyrene in the flue gas reaches 15 μg / m 3 , at the same time containing liquid oil droplets 40mg / m 3 , carbon black dust 20mg / m 3 , all exceeding local emission standards. Adopt this patent equipment to manage.

[0068] A device for trapping and removing benzopyrene in flue gas, the front view is as follows figure 1 As shown, the top view is as figure 2 As shown, the left view is as image 3 As shown, the schematic diagram of the trapping bundle structure is shown in Figure 4 As shown, the structure includes: a shell 1, a trapping chamber 2, a flue gas inlet 3, a flue gas outlet 4, a pressure equalizing plate 6, an upper cover plate 7, a liquid collection tank 8, a liquid discharge port 9 and a smoke exhaust chimney 10; The collection chamber is filled with capture bundles 11; the material of the capture bundl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com