Rodent pad layer and preparation method of rodent pad layer

A technology for rodents and cushions, which is applied in the field of new rodent cushions and its preparation, can solve problems such as inability to store for a long time, insufficient water absorption, non-standardized production and aseptic packaging, so as to avoid cages and space pollution , The replacement process saves time and effort, and is beneficial to animal health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] ①Preparation of nano-zinc oxide finishing agent: heating zinc acetate dihydrate in a water bath at 80°C, stirring and dissolving in 5 times the volume or mass of absolute ethanol, cooling to obtain solution A; change the mass to zinc acetate dihydrate 1 / 20 lithium hydroxide monohydrate is dissolved in 10 times the volume or mass of absolute ethanol, and ultrasonic treatment is performed for 10 minutes to obtain solution B; under strong stirring, slowly drop solution B into solution A to obtain nano zinc oxide finishing Agent stock solution

[0041] ②Preparation of copper sulfate finishing agent: Dissolve copper sulfate with a mass of 1 / 2 of zinc acetate dihydrate in an ethanol solution of 20 times the volume or mass at room temperature. The mass concentration of the ethanol solution is 10% to produce copper sulfate Finishing agent stock solution;

[0042] ③Finishing of non-woven fabric: Take 2 parts volume of nano-zinc oxide finishing agent stock solution and 1 part volume...

Embodiment

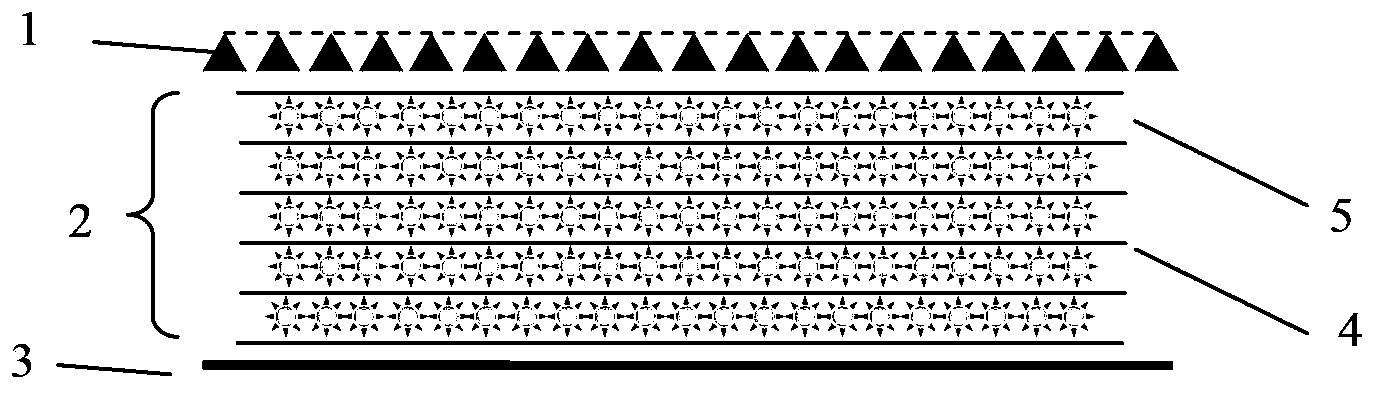

[0049] The three-layer structure of this new rodent cushion is separately produced and processed, and finally formed by thermal bonding. This embodiment specifically follows the following steps:

[0050] (1) Diversion layer

[0051] Using the existing double-effect (surface hydrophilic, bottom surface water repellent) perforated non-woven three-dimensional guide layer material (polypropylene resin), the quantitative is 30-50g / m 2 . The material has a funnel-shaped structure with pores, and the surface tension of the liquid makes it oriented to infiltrate into it. When the liquid flows in, the pores make the lower penetration resistance almost zero, increasing the infiltration volume; the infiltrated liquid is not easy to produce concentric circular diffusion. Instead, it falls into the water at a single point, directing the liquid vertically into the core layer.

[0052] (2) Absorbing core layer

[0053] The main raw materials for manufacturing the absorbent core layer are non-woven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com