Pig manure and urine fermentation tank for pig farm

A pig manure tank and pig farm technology, applied in the field of animal husbandry, can solve the problems of biogas accumulation, no rapid separation of pig manure and urine, inconvenient cleaning, etc., so as to facilitate cleaning, increase buffer, and prevent damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

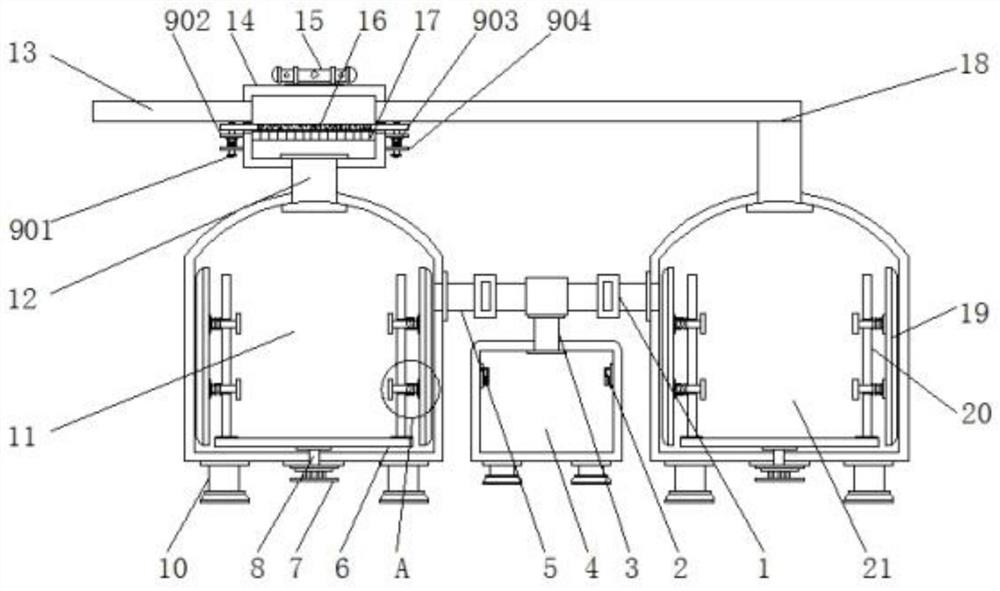

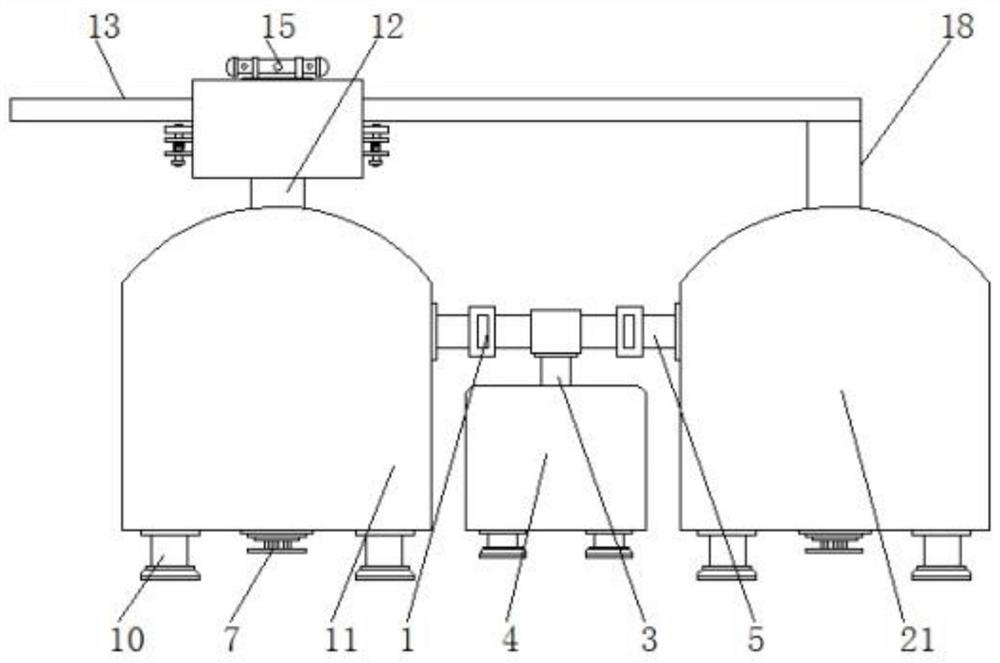

[0024] Example 1: See Figure 1-4 , a pig manure and urine fermentation tank for pig farms, comprising a biogas tank 4, a branch pipe 5 and a pig manure tank 21, one side of the pig manure tank 21 is provided with a biogas tank 4, and one side of the biogas tank 4 is provided with a Pig urine tank 11, pig manure tank 21, biogas tank 4 and both sides of the bottom of pig urine tank 11 are provided with two legs 10, and between pig manure tank 21 above biogas tank 4 and pig urine tank 11 side is provided with Branch pipe 5, and a main pipe 3 is installed at the middle of the bottom end of the branch pipe 5, and the bottom end of the main pipe 3 extends to the top inside the biogas digester 4, and the outer walls of the branch pipe 5 on both sides of the main pipe 3 are equipped with solenoid valves 1 and pig urine pool 11 A separation box 14 is arranged above the top of the separation box 14, and a connecting pipe 12 is installed at the bottom of the separation box 14, and the b...

Embodiment 2

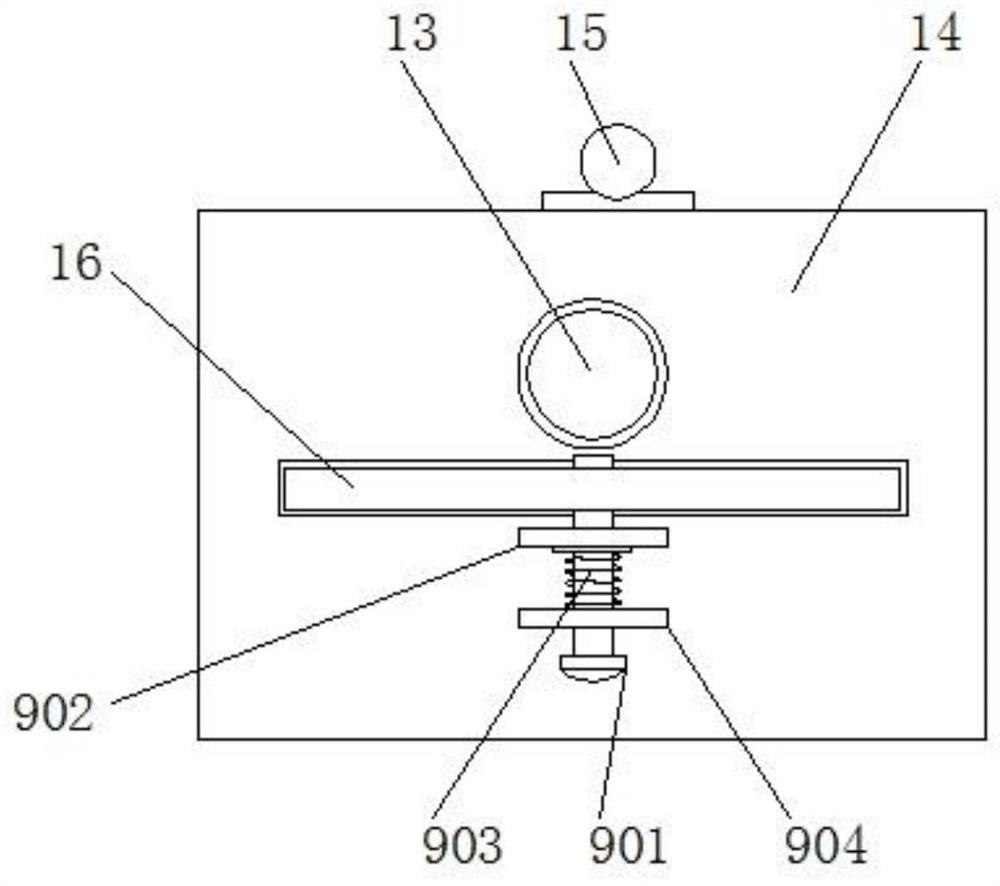

[0028] Embodiment 2: The assembly and disassembly structure 9 comprises an insertion rod 901, a first fixed plate 902, an installation spring 903 and a second fixed plate 904, and the first fixed plate 902 is arranged on both sides of the separation box 14 below the filter screen 16, and the second fixed plate 902 Both sides of the separation box 14 below a fixed plate 902 are provided with a second fixed plate 904, and the bottom ends of the second fixed plate 904 are equipped with inserting rods 901, and the tops of the inserting rods 901 penetrate to the top of the filter screen 16;

[0029] The outer wall of the insertion rod 901 between the first fixing plate 902 and the second fixing plate 904 is provided with a mounting spring 903, and the top and bottom ends of the mounting spring 903 are respectively welded to the first fixing plate 902 and the second fixing plate 904;

[0030] Specifically, such as figure 1 , figure 2 with image 3 As shown, when using this mechan...

Embodiment 3

[0031] Embodiment 3: the volumes of the pig manure tank 21 and the pig urine tank 11 are equal, and the volumes of the pig manure tank 21 and the pig urine tank 11 are far greater than the volume of the biogas tank 4;

[0032] Gas concentration sensors 2 are arranged on both sides inside the biogas digester 4, the type of the gas concentration sensor 2 can be JP61M, and the gas concentration sensors 2 are arranged symmetrically through the center line of the biogas digester 4;

[0033] Specifically, such as figure 1 with figure 2 As shown, when using this mechanism, the gas concentration sensor 2 can monitor the concentration of biogas in the biogas tank 4 in real time. When the internal biogas concentration is too high, the gas concentration sensor 2 receives the signal and transmits the signal to the single-chip microcomputer 15, and the single-chip microcomputer 15 receives the signal. The solenoid valve 1 is controlled to be closed to prevent the biogas digester 4 from exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com