Inorganic building sound absorption material and preparation method thereof

A sound-absorbing material and construction technology, applied in the field of sound-absorbing materials, can solve the problems of particle detachment, sound-absorbing effect decline, poor durability, etc., to achieve the effect of improving water repellency, avoiding shedding, and ensuring durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

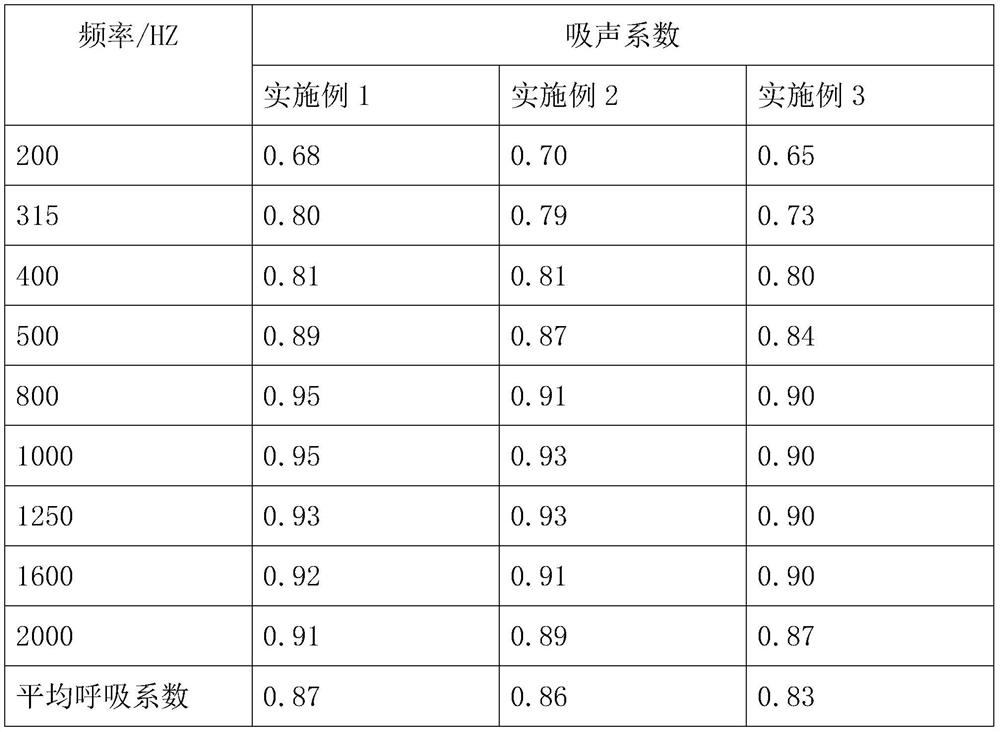

Embodiment 1

[0032] In the embodiment of the present invention, an inorganic building sound-absorbing material provided includes the following raw materials in mass percentage:

[0033] Modified porous ceramsite 45%

[0034] Modified expanded perlite 10%

[0035] Cement (sulfoaluminate cement) 20%

[0036] Silica fume 15%

[0037] Inorganic fiber (glass fiber) 2%

[0038] Foaming agent (sodium lauryl sulfate) 5%

[0039] Tackifier (polyethylene oxide) 3%

[0040] For the above components, its preparation method is as follows:

[0041] S1. Raw material pretreatment: Prepare modified aggregate mixed with modified porous ceramsite and modified expanded perlite, including:

[0042] Mix porous ceramsite and expanded perlite at a mass ratio of 45:10 to obtain a mixture;

[0043] Mix organosilane, low-molecular organosiloxane, curing agent, surface active treatment agent and water at a ratio of 80:20:0.2:0.05:899.75 to obtain a hydrophobic treatment modifier solution;

[0044] Immerse the...

Embodiment 2

[0051] In the embodiment of the present invention, an inorganic building sound-absorbing material provided includes the following raw materials in mass percentage:

[0052] Modified porous ceramsite 40%

[0053] Modified expanded perlite 8%

[0054] Cement (sulfoaluminate cement) 27%

[0055] Silica fume 13%

[0056] Inorganic fiber (glass fiber) 3%

[0057] Foaming agent (sodium lauryl sulfate) 4%

[0058] Tackifier (polyethylene oxide) 5%

[0059] For the above components, its preparation method is as follows:

[0060] S1. Raw material pretreatment: Prepare modified aggregate mixed with modified porous ceramsite and modified expanded perlite, including:

[0061] Mix porous ceramsite and expanded perlite at a mass ratio of 10:2 to obtain a mixture;

[0062] Mix organosilane, low-molecular organosiloxane, curing agent, surface active treatment agent and water at a ratio of 80:20:0.2:0.05:899.75 to obtain a hydrophobic treatment modifier solution;

[0063]Immerse the mi...

Embodiment 3

[0070] In the embodiment of the present invention, an inorganic building sound-absorbing material provided includes the following raw materials in mass percentage:

[0071] Modified porous ceramsite 37%

[0072] Modified expanded perlite 11%

[0073] Cement (sulfoaluminate cement) 29%

[0074] Silica fume 10%

[0075] Inorganic fiber (glass fiber) 1%

[0076] Foaming agent (sodium lauryl sulfate) 8%

[0077] Tackifier (polyethylene oxide) 4%

[0078] For the above components, its preparation method is as follows:

[0079] S1. Raw material pretreatment: Prepare modified aggregate mixed with modified porous ceramsite and modified expanded perlite, including:

[0080] Mix porous ceramsite and expanded perlite at a mass ratio of 37:11 to obtain a mixture;

[0081] Mix organosilane, low-molecular organosiloxane, curing agent, surface active treatment agent and water at a ratio of 80:20:0.2:0.05:899.75 to obtain a hydrophobic treatment modifier solution;

[0082] Immerse the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com