Bacteriostatic polyvinylidene fluoride porous membrane and preparation method thereof

A technology of polyvinylidene fluoride and porous membrane, which is applied in the field of antibacterial polyvinylidene fluoride porous membrane and its preparation, can solve the problems of difficulty in ensuring compatibility, low dosage, and difficulty in dispersing pure antibacterial agents, and achieves a reduction in Compatibility requirements, easy industrialization, and the effect of broadening the range of choices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

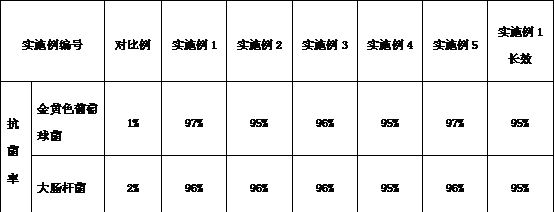

Examples

Embodiment 1

[0056] 1) Preparation of modified masterbatch for the preparation of antibacterial polyvinylidene fluoride nanoporous membrane: Grind nano calcium carbonate through a 325 mesh screen, and then add the ground and sieved powder into a high-speed mixer, while stirring Add the perfluorosulfonate solution as a modified additive to the nano-calcium carbonate in the form of spray, and stir at a high speed for 10 minutes; then move the pretreated powder to an ultrasonic processor with high-speed stirring, add PHMG (PH) (i.e. Polyhexamethylene guanidine phosphate, a derivative of polyhexamethylene guanidine) water preparation, stir under 30KHZ ultrasonic conditions for 20min, then add high molecular weight polyvinylidene fluoride with MFR of 2.0g / 10min (230℃, 21.6kg). Ethylene powder, stir evenly; then introduce the mixture into the twin-screw extruder, knead at 200 ℃, and at the same time multi-stage vacuuming to discharge small molecular volatiles (ie water vapor and low boiling point...

Embodiment 2

[0067] 1) Modified masterbatch for the preparation of antibacterial polyvinylidene fluoride porous membrane: Grind nano calcium carbonate through a 325-mesh sieve, and then add the ground and sieved powder into a high-speed mixer. The fluorocarboxylic acid solution was added to the nano-calcium carbonate in the form of spray, and stirred at a high speed for 10 minutes; then the pretreated powder was moved to an ultrasonic processor with high-speed stirring, and a water agent containing carboxymethyl chitosan was added, under the condition of 30KHZ Stir for 20min, then add high molecular weight polyvinylidene fluoride powder with MFR of 2.0g / 10min (230°C, 21.6kg), stir evenly; then introduce the mixture into a twin-screw extruder, knead at 190°C, and simultaneously multi-stage Vacuumize to discharge small molecule volatiles (ie water vapor and low boiling point substances), and the vacuum degree is -0.4~-0.7bar.

[0068] The weight percent of each component of the prepared modi...

Embodiment 3

[0076] 1) Preparation of antibacterial nano calcium carbonate masterbatch: Grind nano calcium carbonate through a 325 mesh screen, then add the ground and sieved powder into a high-speed mixer, while stirring, spray the perfluorocarboxylic acid solution in the form of a spray Add nano calcium carbonate, stir at high speed for 10min; then move the pretreated powder to an ultrasonic processor with high speed stirring, add PHMG (GL) (ie polyhexamethylene guanidine gluconate, polyhexamethylene guanidine) A derivative of guanidine) water agent, stir at 30KHZ for 20min, then add high molecular weight polyvinylidene fluoride powder with MFR of 2.0g / 10min (230℃, 21.6kg), stir evenly; Screw extruder, kneading at 200 °C, and at the same time multi-stage vacuuming to discharge small molecular volatiles (ie water vapor and low boiling point substances), the vacuum degree is -0.5~-0.8bar.

[0077] The weight percent of each component of the prepared modified master batch is as follows:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com