Automatic doffing system for twisting production

An automatic doffing and twisting technology, applied in textiles and papermaking, can solve problems such as low operating efficiency and difficulty in ensuring product quality consistency, and achieve the effects of eliminating manual operations, simplifying equipment, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

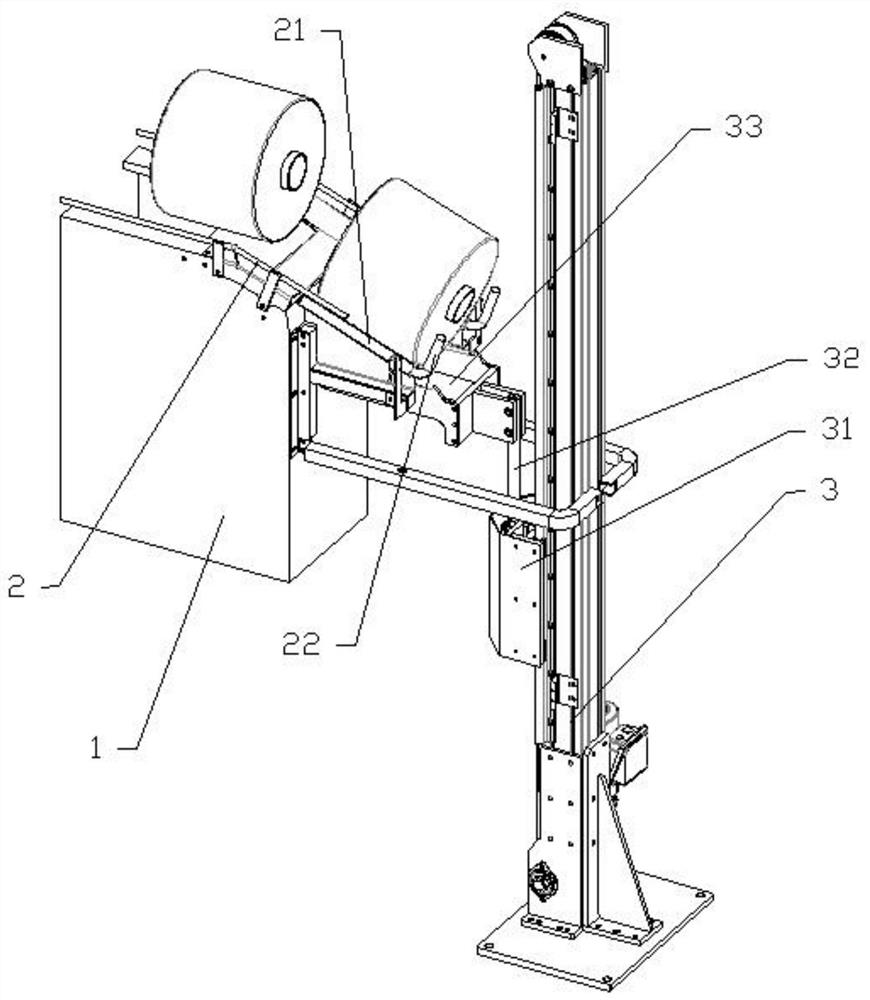

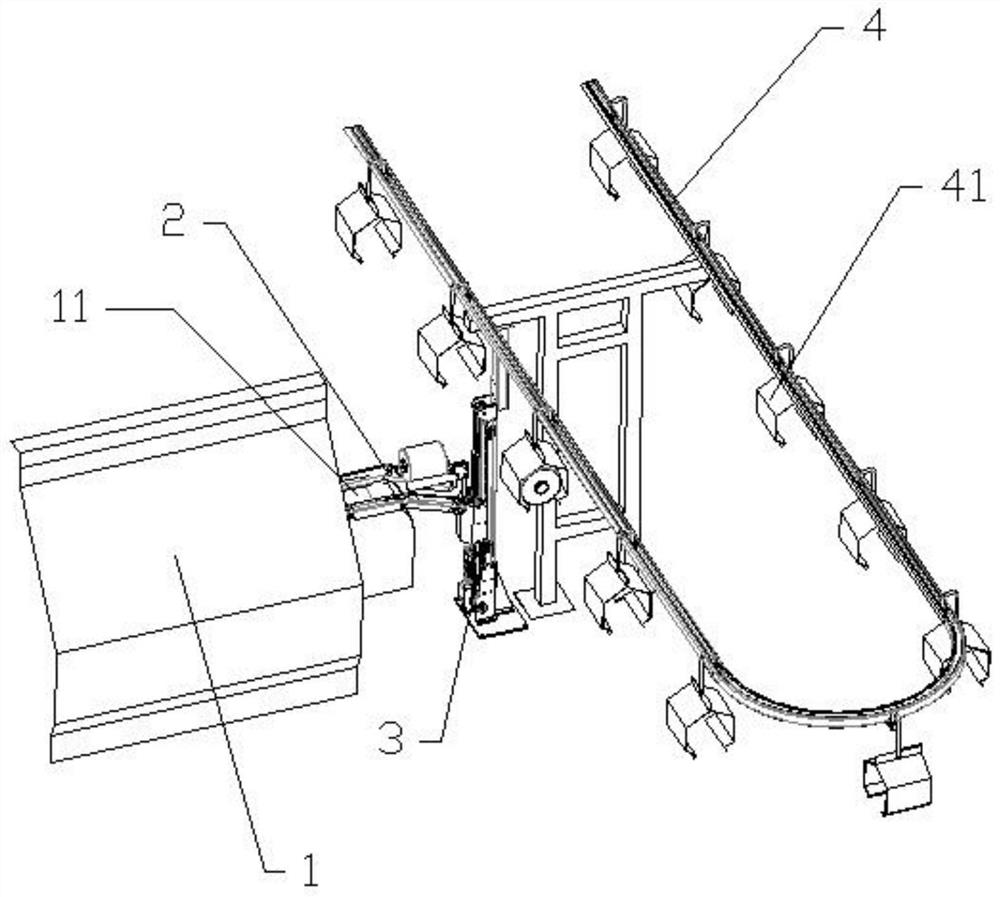

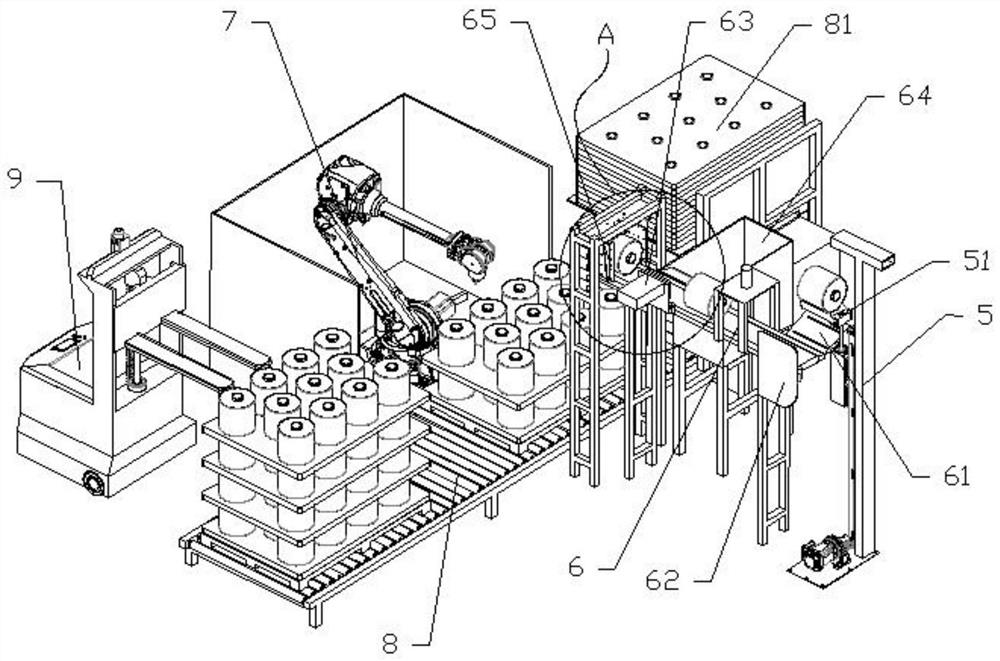

[0029] The present invention proposes an automatic doffing system for twisted yarn production, which includes a twisting machine host 1, a guiding and positioning device, an upper yarn lifting device, a suspension conveying device, a lower yarn lifting device and Transshipment device, the twisting machine host 1 is provided with a conveyor belt 11 corresponding to each twisting roller, the guide positioning device is arranged at the tail end of the conveyor belt 11, the upper yarn lifting device, the suspension conveying device, and the lower yarn lifting device Cooperate sequentially to transport the yarn rolls from the twisting machine host 1 to the transfer device, and finally the transfer device transports the neatly stacked yarn rolls into the warehouse for storage.

[0030] The present invention also includes a master control device, which is electrically connected with the main machine 1 of the twisting machine, the guide and positioning device, the upper yarn lifting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com