Intelligent maintenance automatic lifting and shifting device

A technology of automatic lifting and shifting device, applied in the directions of brake parts, transportation and packaging, brake actuators, etc., can solve the problems of intelligent detection mechanical accuracy discount, difficult to carry, etc., to achieve a simple overall structure combination, convenient assembly and Maintenance, adjustment and flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

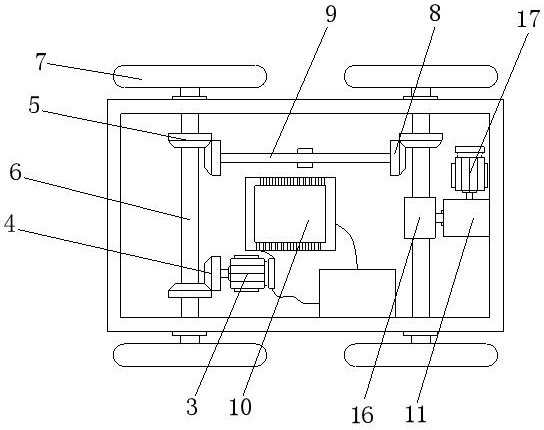

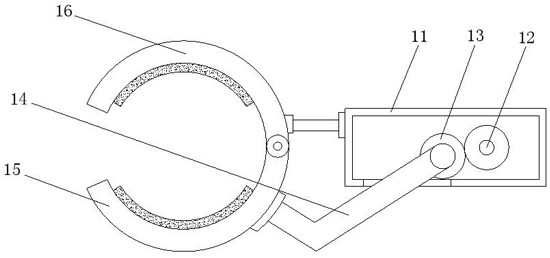

[0029] Embodiment 1, according to Figure 1-3 , Figure 5 , when using the moving function, the external control device sends a signal to the control assembly 10 installed inside the mobile device 2, and the control assembly 10 controls the rotation of the first motor 3 after receiving the signal, and the rotation of the output end of the first motor 3 drives the first cone The gear 4 rotates, through the engagement between the first bevel gear 4 and the second bevel gear 5, and then drives the first transmission rod 6 to rotate, the two first transmission rods 6 are connected by the second transmission rod 9, and the first transmission rod 6 is connected by the second transmission rod 9. A transmission rod 6 drives a total of four wheels 7 installed at both ends to move inside the track 1. When the mobile device 2 is about to move to a designated position, the second motor 17 is controlled by the control component 10 to operate, and the second motor 17 outputs The rotation o...

Embodiment 2

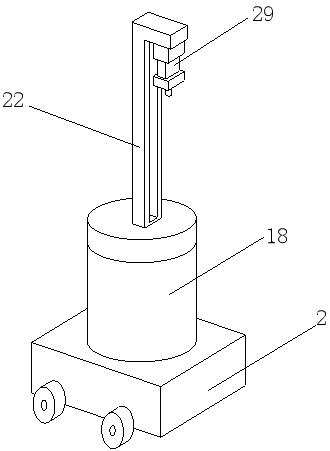

[0030] Embodiment 2, according to figure 1 , Figure 4 and Figure 6-7 , when using the rotation function, an external control device sends a signal to the controller 28, and the controller 28 controls the action of the third motor 24 after receiving the signal, and drives the turntable 25 to rotate through the rotation of the output end of the third motor 24, and then uses the sphere 23 The contacting turntable 25 drives the ball 23 to rotate to change the angle, and then drives the rotating rod 21 to rotate, and further drives the slide rail 22 to rotate. When the angle rotates to the desired angle, the controller 28 sends a signal to control the output of the first electric cylinder 26. end action, drive the brake plate 27 to contact with the sphere 23, realize the locking of the rotation angle, and when the rotation rod 21 rotates, the controller 28 can also act through the controlled second electric cylinder 29 and be installed on the connecting block 30 The advanced de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com