Motor temperature control device and method

A technology for controlling device and motor temperature, applied in motor control, electromechanical device, emergency protection circuit device, etc., can solve problems such as motor temperature rise, insulation material damage, motor burn-in, etc. The effect of short-circuit burn-in and automatic cooling in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

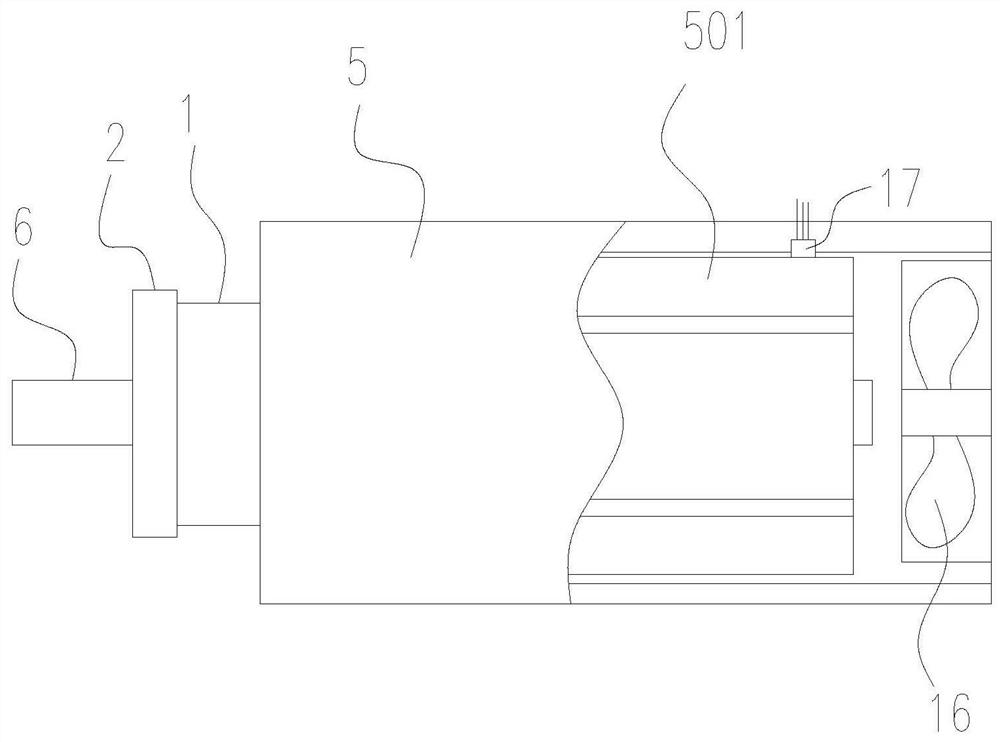

[0028] like figure 1 As shown, a motor temperature control device includes a temperature sensor 17, a motor driver, and a cooling fan 16. The temperature sensor is fixed on the motor 5 housing, and the temperature sensing part of the temperature sensor is in contact with the motor coil 501. The temperature change of the control motor power changes and the rotating speed of cooling fan 16. The cooling fan is arranged on the rear end cover of the motor. The motor may be a servo motor, and the motor driver may be a servo motor driver.

[0029] As a method of motor temperature control: when the measured temperature of the temperature sensor is lower than the first temperature setting value (such as 120°C), the motor runs normally; when the measured temperature rises above the second temperature setting value (such as 130°C), Reduce the current of the motor through the motor driver; when the measured temperature rises above the third temperature setting value (such as 140°C), the...

Embodiment 2

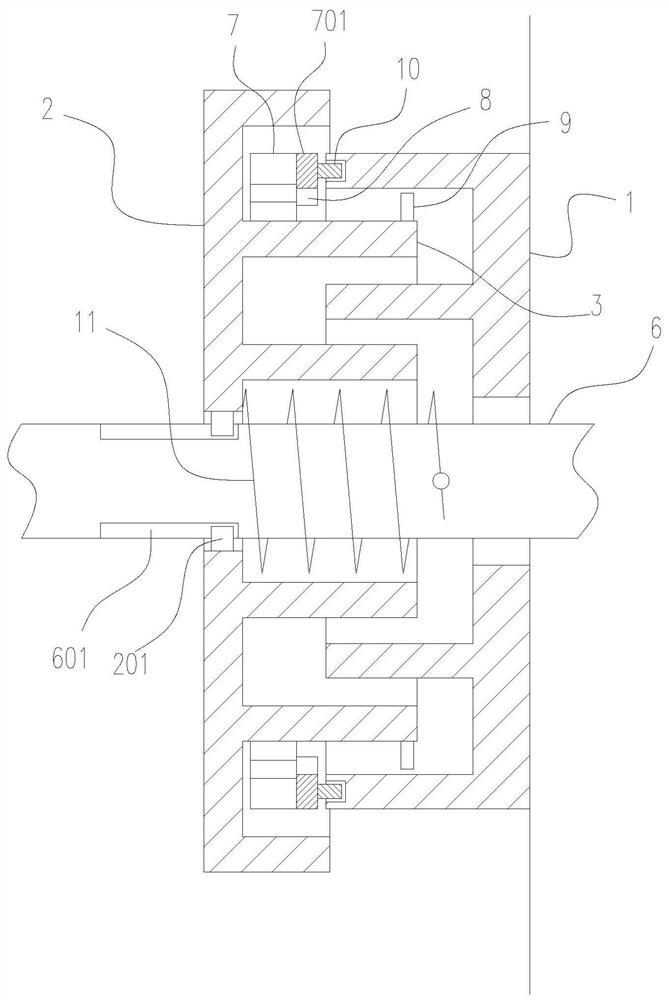

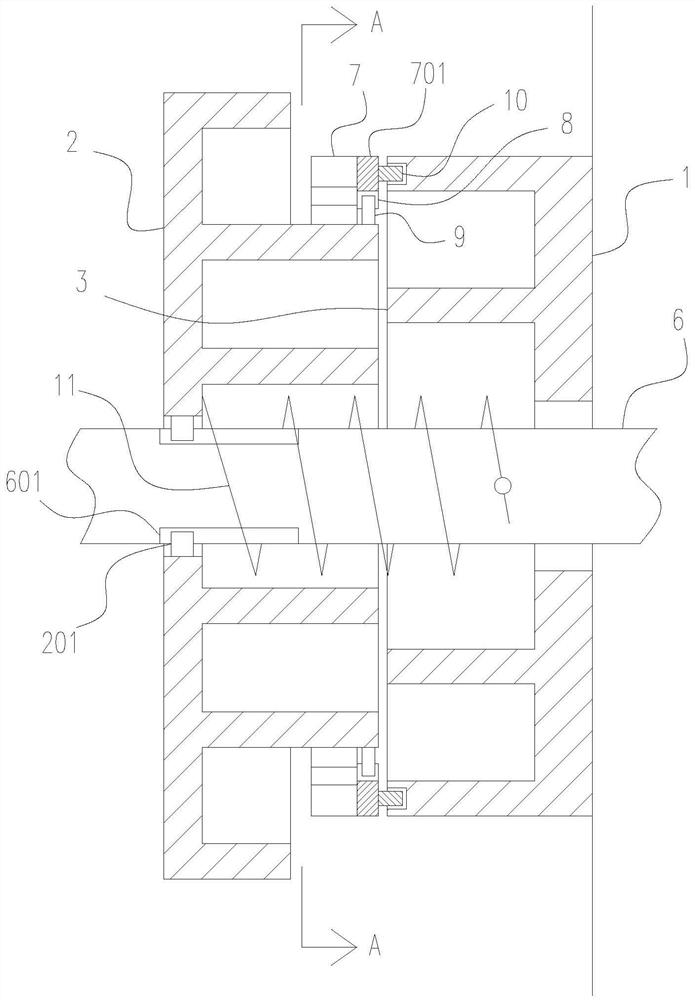

[0032] like figure 2 , 3As shown in , 4, the difference from the above-mentioned embodiment is that a shaft rotating sealing heat dissipation device is provided between the motor shaft and the motor end cover, and the shaft rotating sealing heat dissipation device includes a shaft concentric ring 2 arranged on the rotating shaft 6 And the end concentric ring 1 arranged on the end cover, the coaxial radial staggered interval between the shaft concentric ring and the ring body 3 of the end concentric ring, so as to form a circuitous path of air flow and reduce the entry of dust and impurities from the outside To the gap between the rotating shaft and the end cover, the shaft concentric ring is coaxially slidably arranged on the rotating shaft, the rotating shaft is provided with an axial slide groove 601, and the shaft concentric ring is provided with a slide fit in the axial slide groove Block 201, so that the concentric ring of the shaft can be rotated by the rotating shaft,...

Embodiment 3

[0040] like Figure 5 , 6 As shown, the difference from the above embodiment is that the axial telescopic control device is a shape memory alloy spring 12, the shape memory alloy spring is supported between the concentric ring of the shaft and the rotating shaft, and the concentric ring of the shaft is arranged on the rotating shaft. Position part 14, such as an axial limit snap ring, a supporting spring 13 is supported between the concentric ring limit part of the shaft and the concentric ring of the shaft. When the temperature is higher than the phase transition temperature of the shape memory alloy, the shape memory alloy spring stretches The length overcomes the supporting force of the support spring, so that the concentric ring of the shaft is far away from the concentric ring of the end, so that the inward locking part and the outward locking part are in contact with each other in the direction of rotation. When the temperature is lower than the phase transition temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com