Omnidirectional loudspeaker

A loudspeaker, extending technology, applied in the field of loudspeakers, can solve the problems of large load mass, many phase cancellation areas, and increase the sound range, etc., to achieve the effects of various installation forms, preventing sound short-circuits, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

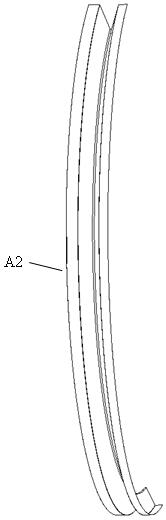

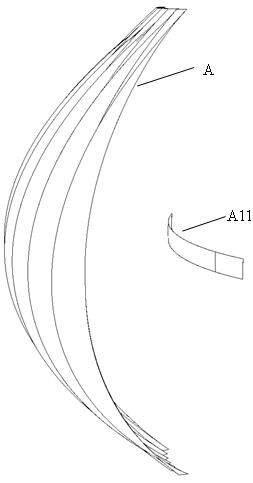

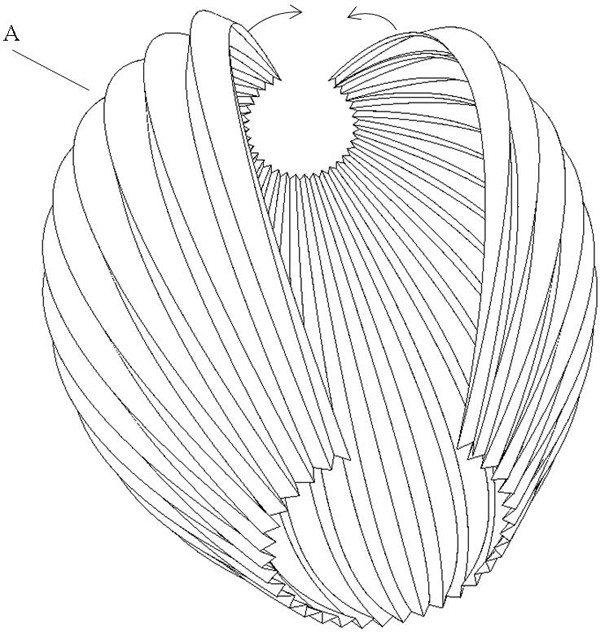

[0061] figure 1 and figure 2 A schematic diagram of Example 1 of the present invention is shown. According to the outer surface profile of the shape of the diaphragm A of the loudspeaker of this embodiment of the present invention, there are only two outer surfaces of closed hollow spheres that are open at both ends of the axial direction; the diaphragm A is partially smooth and partially wrinkled, thereby ensuring its Sound radiation characteristics and structural strength; the diaphragm A of Example 1 is spliced by four non-deformable parts A1 and four deformable parts A2 with the same shape and size and certain rigidity and toughness. Diaphragm A should be as light as possible in order to have minimum inertial mass, preferably, non-deformable part A1 is a thin aluminum sheet with shallower grooves and / or inlaid with other types of materials such as copper to improve strength and vibration characteristics , the deformable part A2 is a rubber sheet.

Embodiment 1

[0062] In Embodiment 1, the cross-sectional area of the opening of each cut-off part of the diaphragm A is less than 1 / 3 of the total area of the outer surface of the diaphragm A, and the projected area of the deformable part A2 on the cross-sectional plane of the opening is smaller than that of the diaphragm A. 1 / 3 of the projected area on this section plane.

[0063] The installation direction of the electromagnetic drive unit B makes the diaphragm A driven by the electromagnetic drive unit B, the non-deformable part A1 drives the deformable part A2, and the center of the diaphragm A as a whole is a fixed reference point, and the uniform expansion and contraction.

[0064] Figure 16 , Figure 17 It shows a schematic diagram of the vibration of the diaphragm A, which is a transverse cross-sectional view of the diaphragm suspended and supported on the central support member C. For the sake of clarity, the deformable part A2 is hidden. It can be seen that the non-deform...

Embodiment 2

[0075] Figure 6 It is an exploded schematic diagram of a part of the hidden part of Embodiment 2 of the present invention. For a clear display, the cable X and the deformable part A2 are hidden. The diaphragm A of the loudspeaker of this embodiment is the outer surface of a closed hollow sphere with a part cut off, and the area corresponding to the axial direction of the cut part of the diaphragm A is a dome-shaped non-deformable part A12, and at the same time Four non-deformable parts A1 are distributed in other areas.

[0076] The loudspeakers of this embodiment cannot be installed in cascade in the axial direction of the central support member C, but since the opening at the upper end is replaced by a dome-shaped non-deformable part A12, the effective radiation area is larger and closer to the pulsation ball source. More than one embodiment 2 can be arranged to be used in cascade perpendicular to the axial direction of the central support member C, or the embodiment 2 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com