Blanking method of rotor wafer with boss

A boss and wafer technology is applied in the field of punching rotor discs with bosses, which can solve the problems of low punching efficiency and increased cost, and achieves the problem of processing efficiency and processing cost, and the processing cycle is short. , The effect of simple mold structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

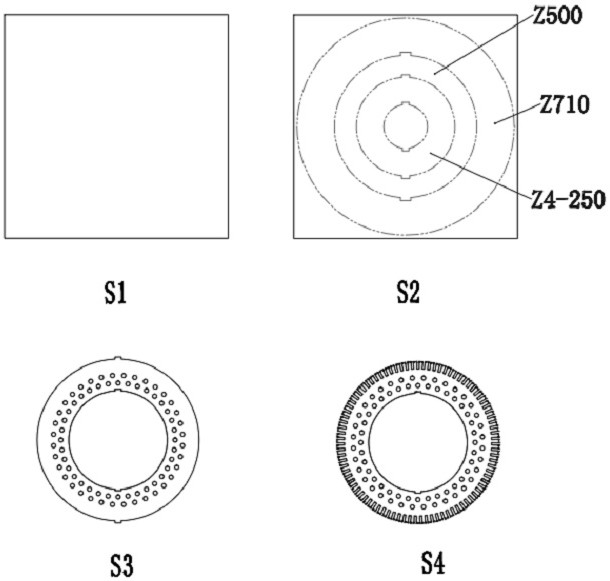

[0031] Please refer to Figure 1-Figure 7 , the punching method of the rotor disc with the boss includes the following steps:

[0032] S1: lower slice;

[0033] S2: Blanking;

[0034] S3: Punch the ventilation hole;

[0035] S4: Grooving and boss cutting.

[0036] In the step S1, the lower sheet of the slitting machine is used; in the step S2, a hydraulic press is used for blanking; in the step S3, a servo-driven high-speed notching machine is used to punch the ventilation holes; in the step S4, a mold is used for punching. trough shape.

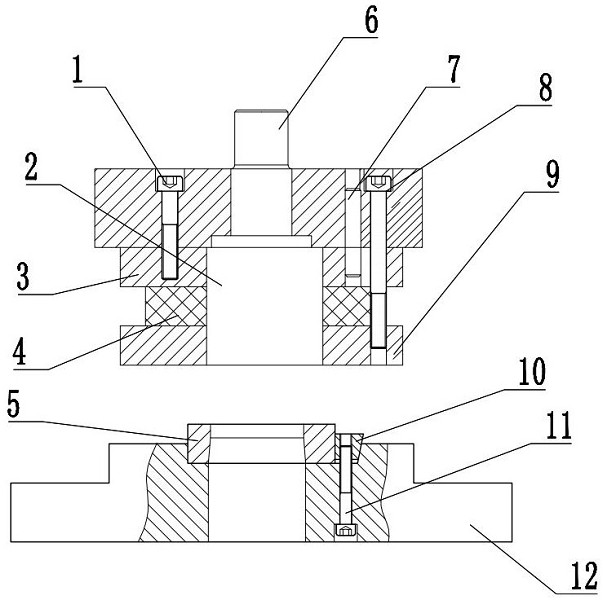

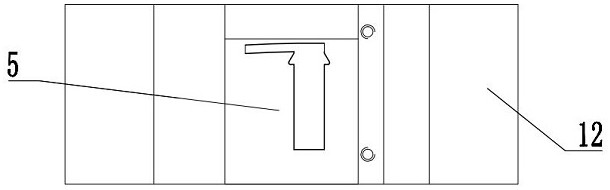

[0037] Described mold comprises upper mold base and lower mold base 12, and the bottom side of described upper mold base is equipped with fixed plate 3, and the bottom side of described fixed plate 3 is equipped with stripper plate 9, and described upper mold base is equipped with Convex mold 2, the top side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com