An Intelligent Reconfigurable Riveting Fixture for Turning Thin Plate Parts

A flip-type, flip-tooling technology, applied in workpiece clamping devices, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of inability to meet product process requirements, low efficiency, etc., to improve hole making and riveting accuracy, easy to use. Effects of manufacturing assembly and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

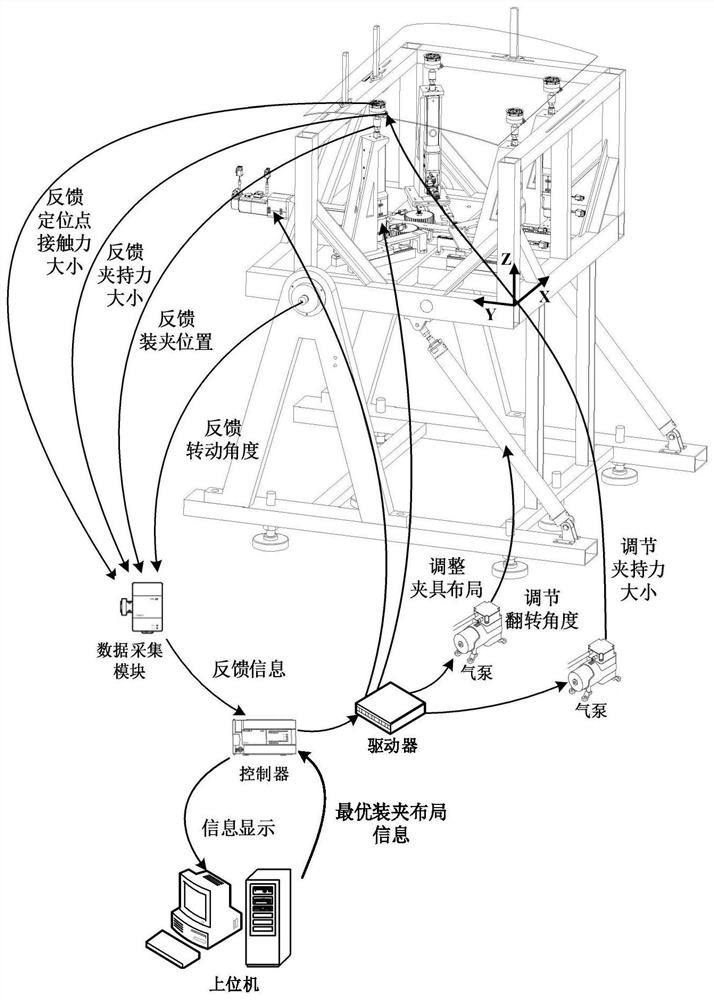

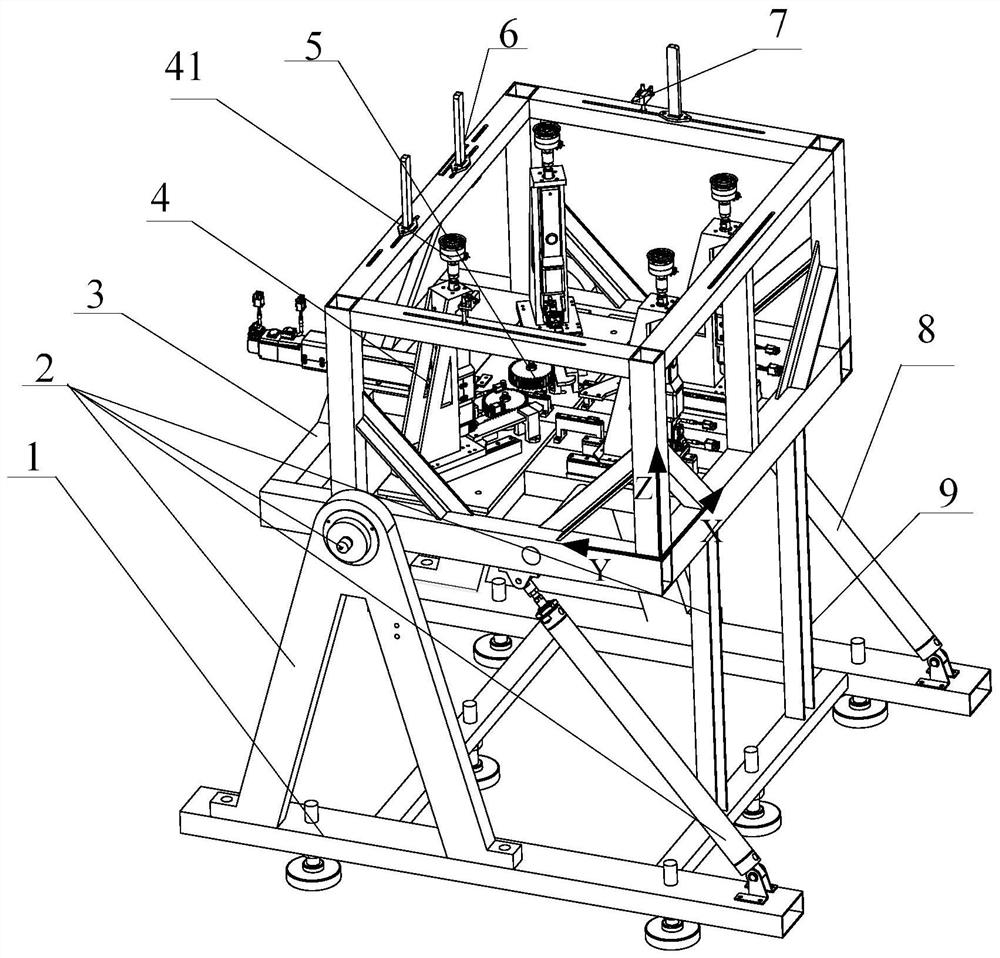

[0035] The overall design and working principle of the intelligent reconfigurable riveting fixture for flip-type thin plate parts is: see figure 1 , an intelligent reconfigurable riveting fixture for flipping thin plate parts, including a multi-point flexible flip tooling machine body, a sensing module and a control module; the sensing module, the control module and the multi-point flexible flipping tooling machine body are electrically connected through N -2-1 positioning method to clamp the skin; the cable displacement sensor 251 equipped with the electric cylinder feeds back the actual position of the positioning point, and the load cell 15 and the vacuum pressure sensor 12 detect the contact force and clamping force of the actual positioning point, The angle sensor 302 detects the actual turning angle of the turning table 3; the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com