Automatic discharging conveying line of sports car band sawing machine

A technology of automatic discharging and band saw machine, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of hidden dangers, time-consuming, laborious, inconvenient, etc., and achieve the effect of reducing hidden dangers, saving human resources, and reducing manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

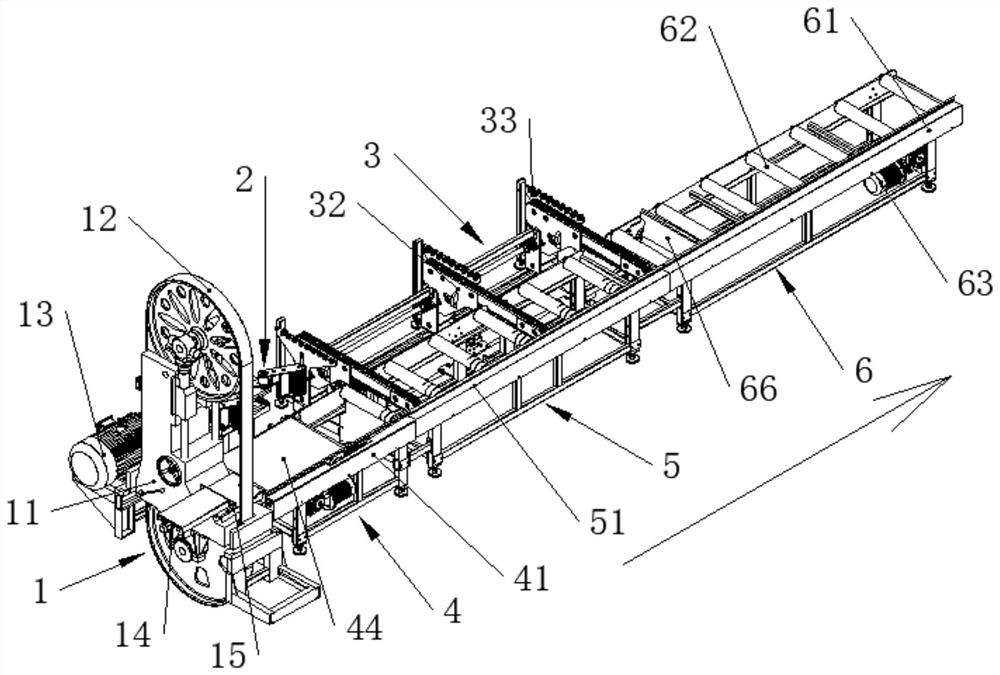

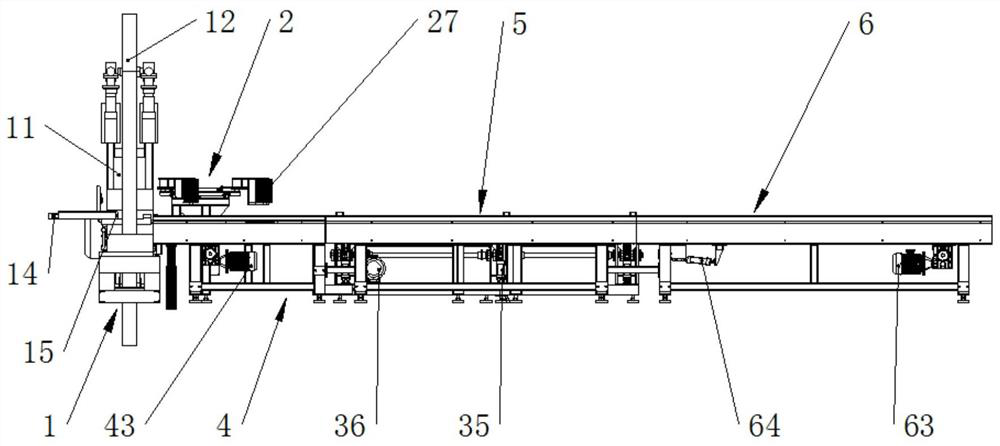

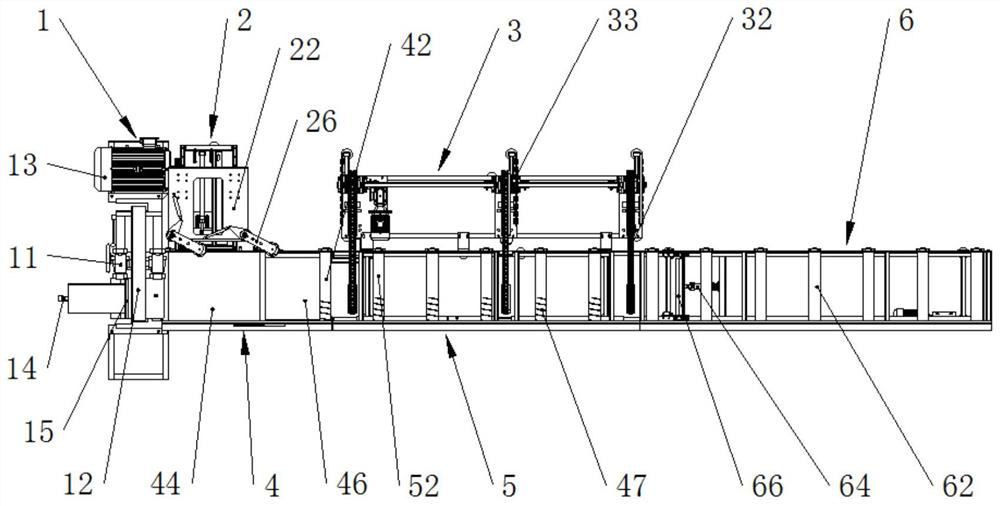

[0037] in, figure 1 The direction of the arrow in indicates the sawing direction of the log.

[0038] see Figure 1-14, an automatic discharge conveying line for a sports car band saw machine, comprising a band saw machine 1, a material holding device 2, a side shifting conveying device 3 and a conveyor belt; the band saw machine 1 is a vertical band saw machine; the band saw machine The machine 1 includes a fuselage 11, a saw blade 12 arranged on the fuselage 11, and a band saw motor 13 arranged outside the fuselage 11; the band saw motor 13 is connected to the saw blade 12 in transmission; The belt is arranged behind the band saw machine 1 along the log sawing direction; the material holding device 2 is arranged above the outer side of the front part of the conveyor belt; the material holding device 2 can provide elastic force to cut the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com