Industrial sewage treatment equipment and use method thereof

A technology for industrial sewage and treatment equipment, applied in water/sewage treatment equipment, water/sewage treatment, water/sludge/sewage treatment, etc. Problems such as dispersion, to achieve the effect of improving flocculation efficiency, improving sewage flocculation efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

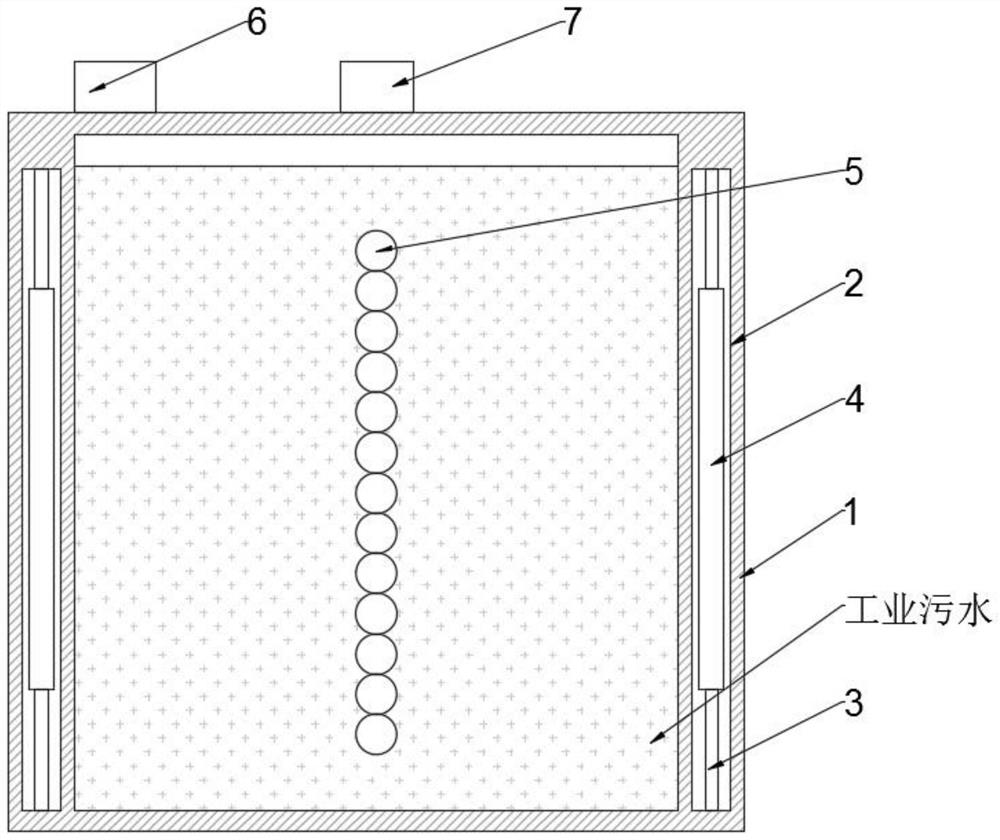

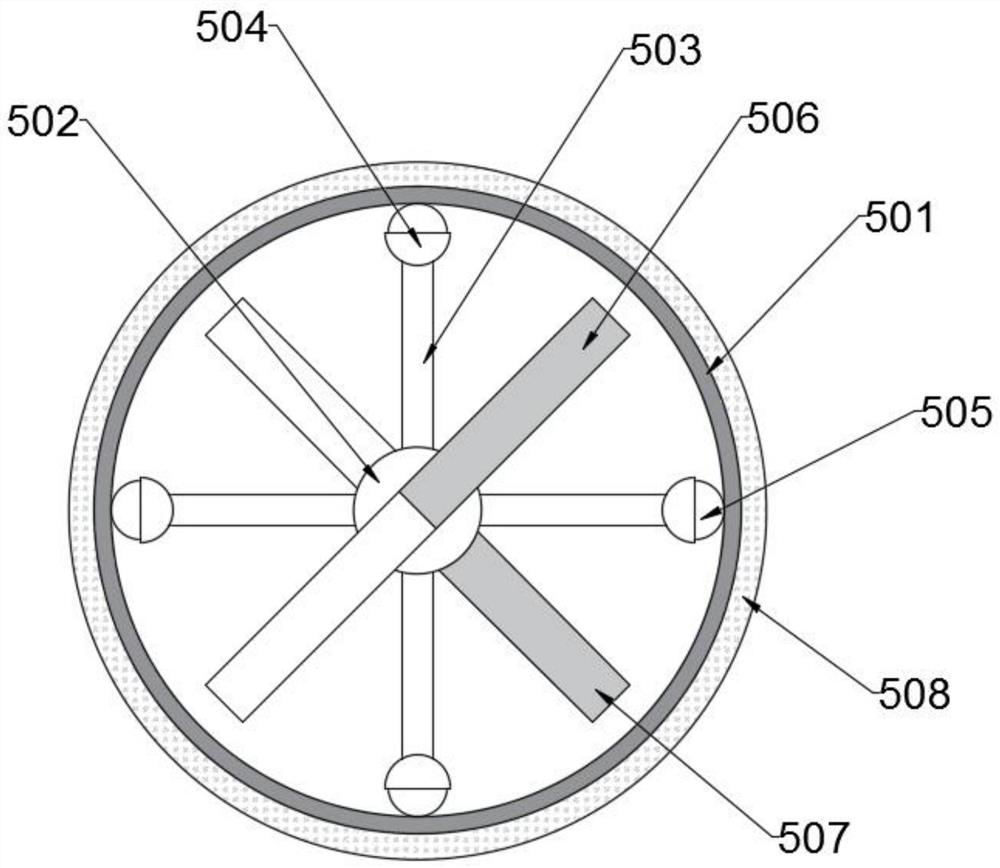

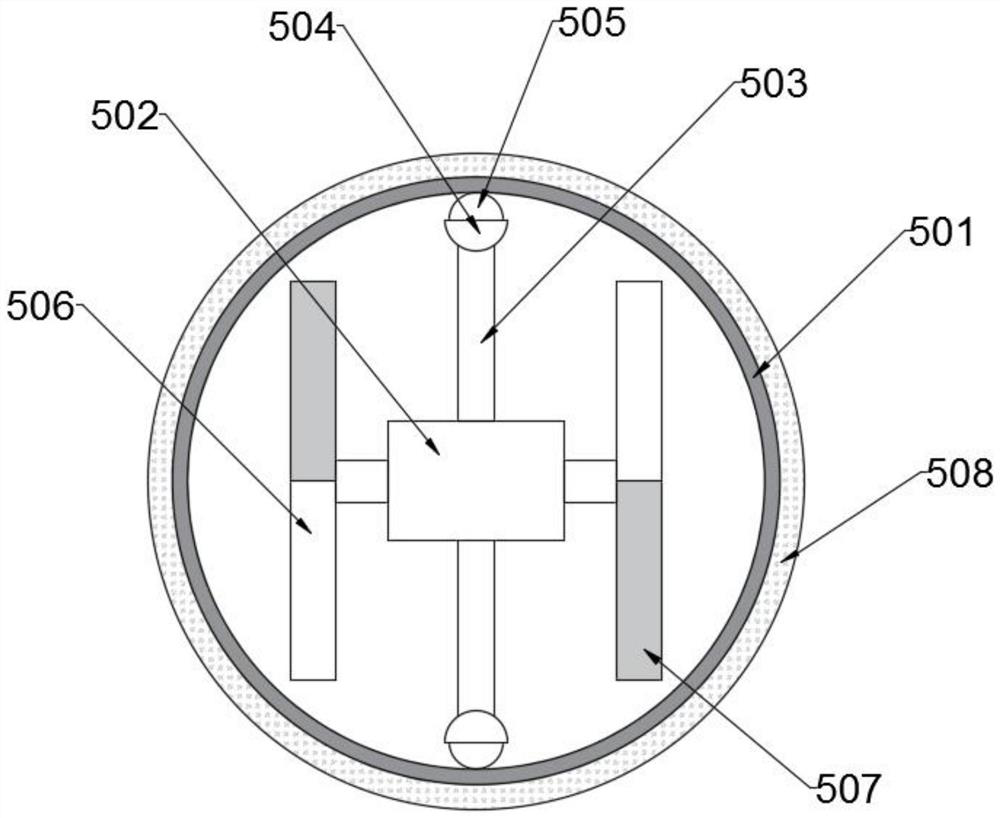

[0042] see Figure 1-5 , a kind of industrial sewage treatment equipment, comprising a rigid plastic cylinder 1, the upper side of the rigid plastic cylinder 1 is respectively connected with a water inlet 6 and a flocculation ball feeding port 7, and also includes a flocculation ball 5 for flocculation, the flocculation ball The ball 5 includes a hollow plastic ball 501 and a mounting cylinder 502 arranged inside the hollow plastic ball 501. The side wall of the mounting cylinder 502 is connected with a plurality of circularly distributed connecting rods 503, and the ends of the connecting rods 503 are connected with a hemispherical cover 504. The inside of the cover 504 is embedded with a ball 505, the ball 505 fits the inner wall of the hollow plastic ball 501, and the inside of the installation cylinder 502 is fixed with two opposite drive motors, and the output ends of the drive motors are respectively connected to the first bar magnet 506 With the second bar magnet 507, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com