A method for the renewable utilization of waste single-base propellants

A single-base propellant and waste technology, which is applied in the direction of a single substance as explosives, explosives, explosives processing equipment, etc., can solve problems such as explosion accidents, excessive solvent consumption, and environmental pollution, and achieve high economic value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

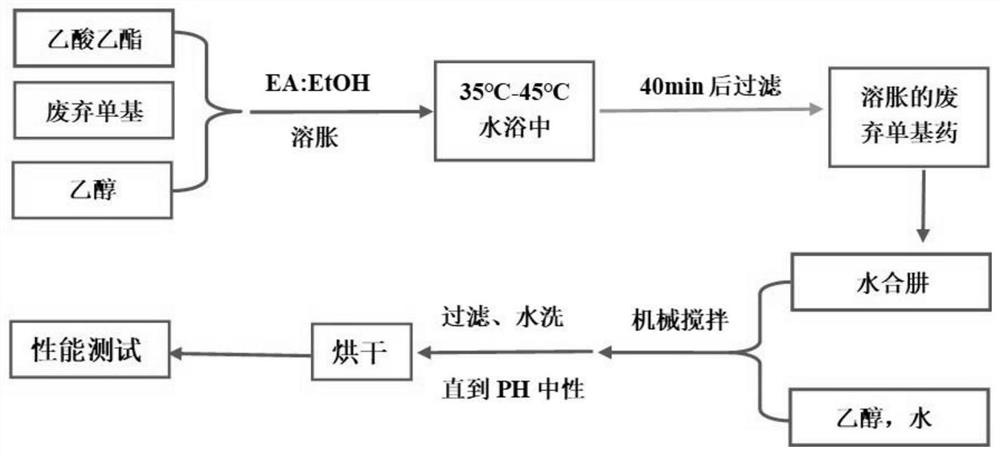

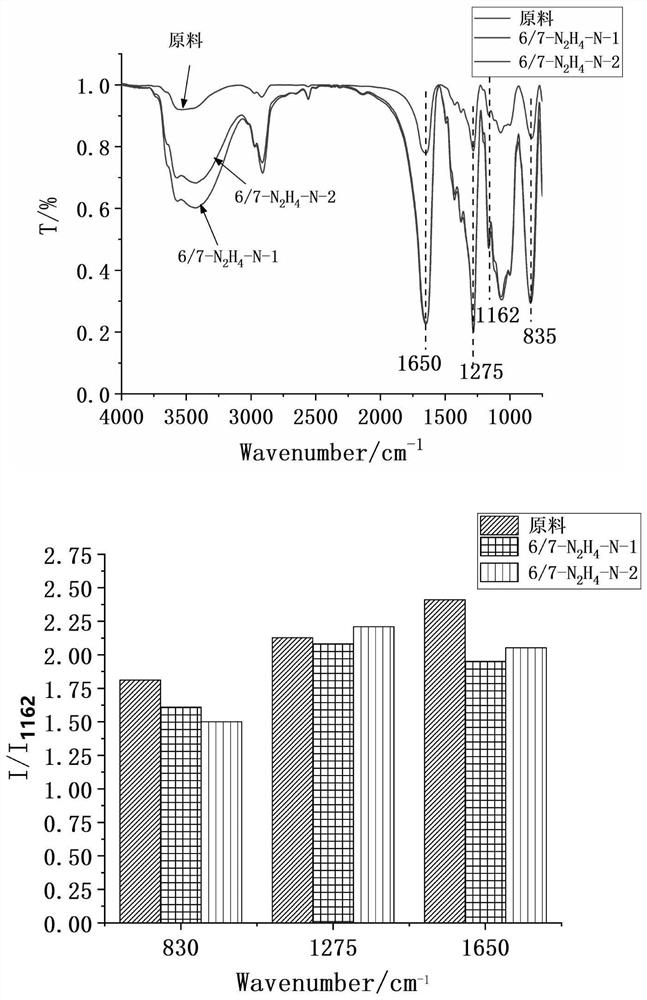

[0036] A method for reusing waste single-base propellants, comprising the following steps:

[0037] 5.7mL of ethyl acetate and 114.3mL of ethanol (volume ratio of 1:20) were configured as a mixed solution, and then the waste single-based propellant was dissolved in the mixed solution of ethyl acetate and ethanol, and the temperature was 35°C in a water bath Ultrasonic treatment is carried out in the medium to fully swell the waste single-base propellant.

[0038] The waste and old single-base propellant after swelling is filtered, and the hydrazine hydrate reducing agent is added in the waste and old single-base propellant after filtering and swelling to carry out reduction reaction: at first 15g concentration is that 80% hydrazine hydrate is dissolved in 105g industrial ethanol (mass concentration is 10%) was preheated to 35°C, then the preheated hydrazine hydrate-ethanol solution was added to the reaction container filled with 60g of waste single-base propellants (the molar ...

Embodiment 2

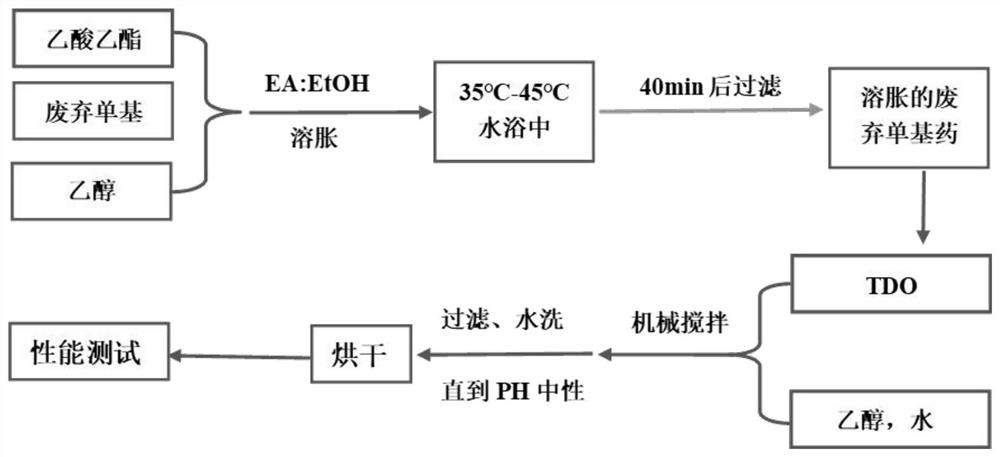

[0044] A method for reusing waste single-base propellants, comprising the following steps:

[0045] 5.7mL of ethyl acetate and 114.3mL of ethanol (volume ratio of 1:20) were configured as a mixed solution, and then the waste single-based propellant was dissolved in the mixed solution of ethyl acetate and ethanol, and the temperature was 38°C. Ultrasonic treatment to fully swell the waste single-base propellant.

[0046] Carry out the reduction reaction of the waste single-base propellant after swelling under the effect of hydrazine hydrate reducing agent: firstly, 37.5g concentration is that 80% hydrazine hydrate is dissolved in 82.5g ethanol (mass concentration is 25%) and preheated to 40 ℃, then Add the preheated hydrazine hydrate-ethanol solution into the reaction container containing 60 g of swollen waste single-base propellant (the molar ratio of the swollen waste single-base propellant to hydrazine hydrate is about 1:11), and the reaction system Heat to 43°C while stirr...

Embodiment 3

[0050] A method for reusing waste single-base propellants, comprising the following steps:

[0051] 5.7mL of ethyl acetate and 114.3mL of ethanol (volume ratio of 1:20) were configured as a mixed solution, and then the waste single-based propellant was dissolved in the mixed solution of ethyl acetate and ethanol, and the temperature was 40°C. Ultrasonic treatment to fully swell the waste single-base propellant.

[0052] Carry out reduction reaction under the effect of hydrazine hydrate reductant to the spent single-base propellant after swelling: first 60g concentration is that hydrazine hydrate of 80% is dissolved in 60g water (mass concentration is 40%) preheating to 45 ℃, then Add the preheated hydrazine hydrate-ethanol solution into a reaction vessel containing 60 g of swollen waste single-base propellant, heat the reaction system to 45°C while stirring to keep the reaction system at a uniform temperature, and react for 32 minutes.

[0053] The reduced product is separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com