Highway drainage ditch dredging equipment

A drainage ditch and highway technology, applied in waterway systems, water supply devices, grain processing and other directions, can solve the problems of high labor intensity, high economic cost, inconvenient cleaning, etc., and achieve the effect of realizing mechanization, improving construction work efficiency and saving construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

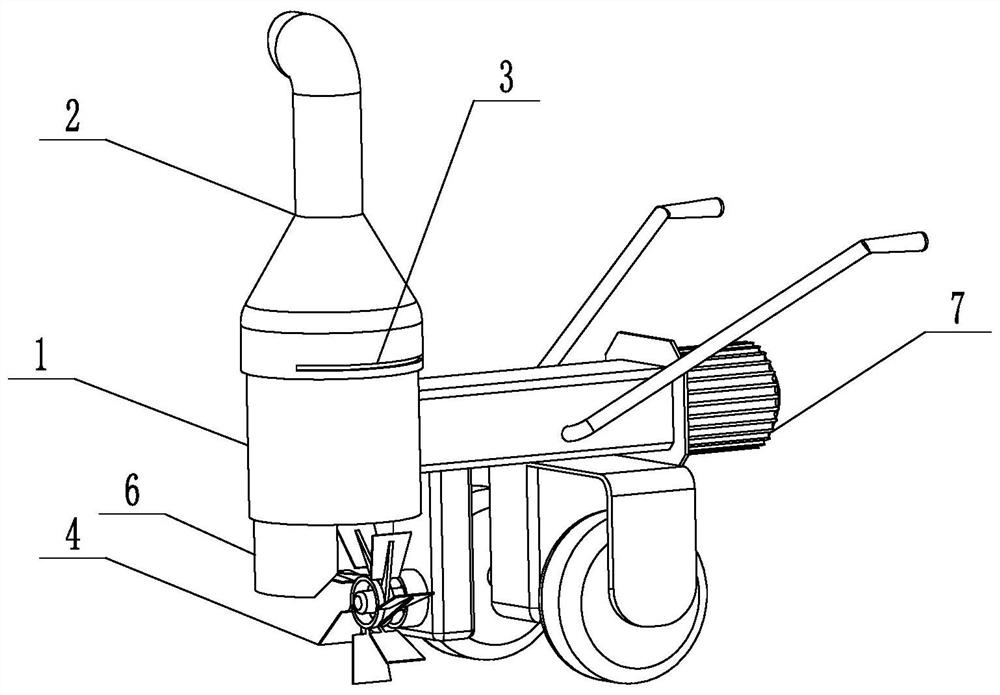

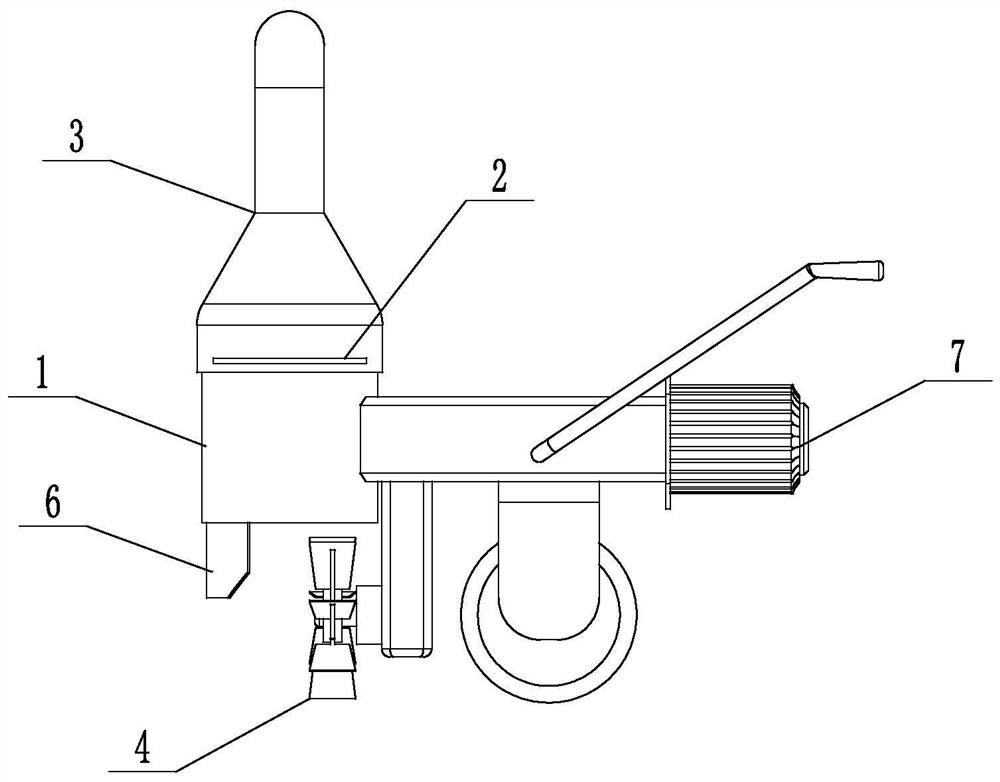

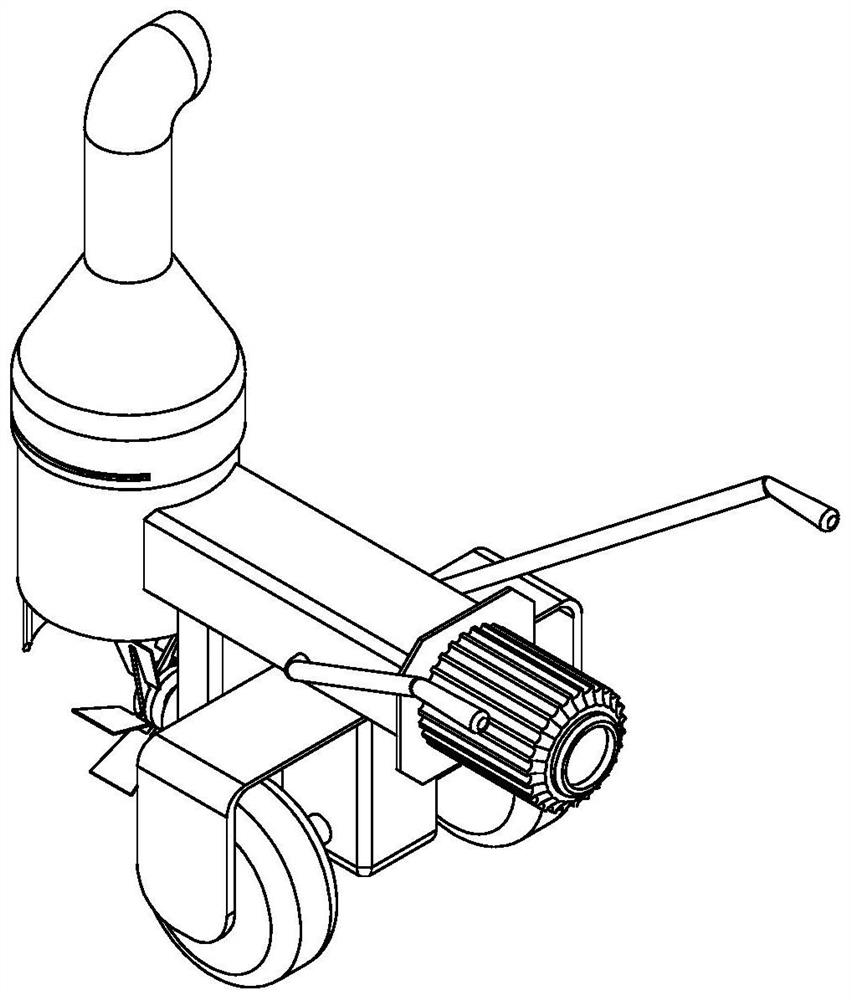

[0025] In order to realize automatic mechanical declogging and dredging, the specific structure of this example includes:

[0026] Including a car body with wheels installed, the front end of the car body relative to the direction of travel is provided with a vertically extending cover body 1, and the cover body 1 is designed as a cylinder with a diameter of 40 cm and a length of 30 cm, which can avoid the cleaning device blade 5 Compared with the cuboid shape, the danger of breaking and collapsing not only saves material, but also reduces the trimmed sundries left in the cover body 1 .

[0027] The top of the cover body 1 is equipped with a throwing tube 2 communicating with it up and down. The throwing tube 2 is 70 cm long, 15 cm in diameter, and weighs 10 kg. The bottom side wall of the split tube is pierced with arc-shaped holes 3 in the circumferential direction. The angle of the arc-shaped bar hole 3 is 120 degrees, and the arc-shaped bar hole 3 is equipped with a tighte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com