Fermented grains feeding device

A technology of fermented grains and working devices, which is applied in the field of wine making, can solve problems such as narrow working space, high labor intensity, and complex process actions, and achieve the effects of simple device structure, improved work efficiency, and improved working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is further described.

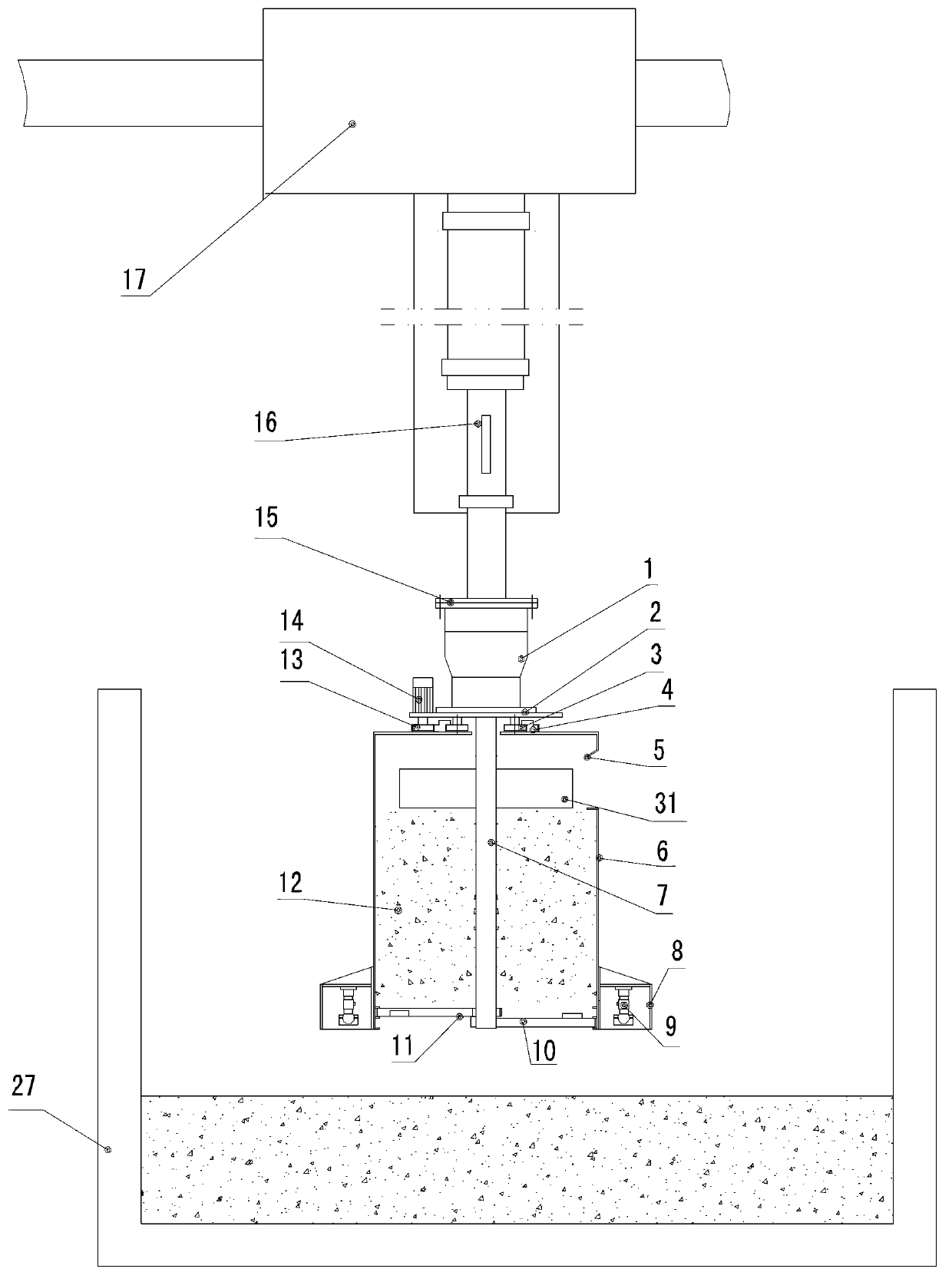

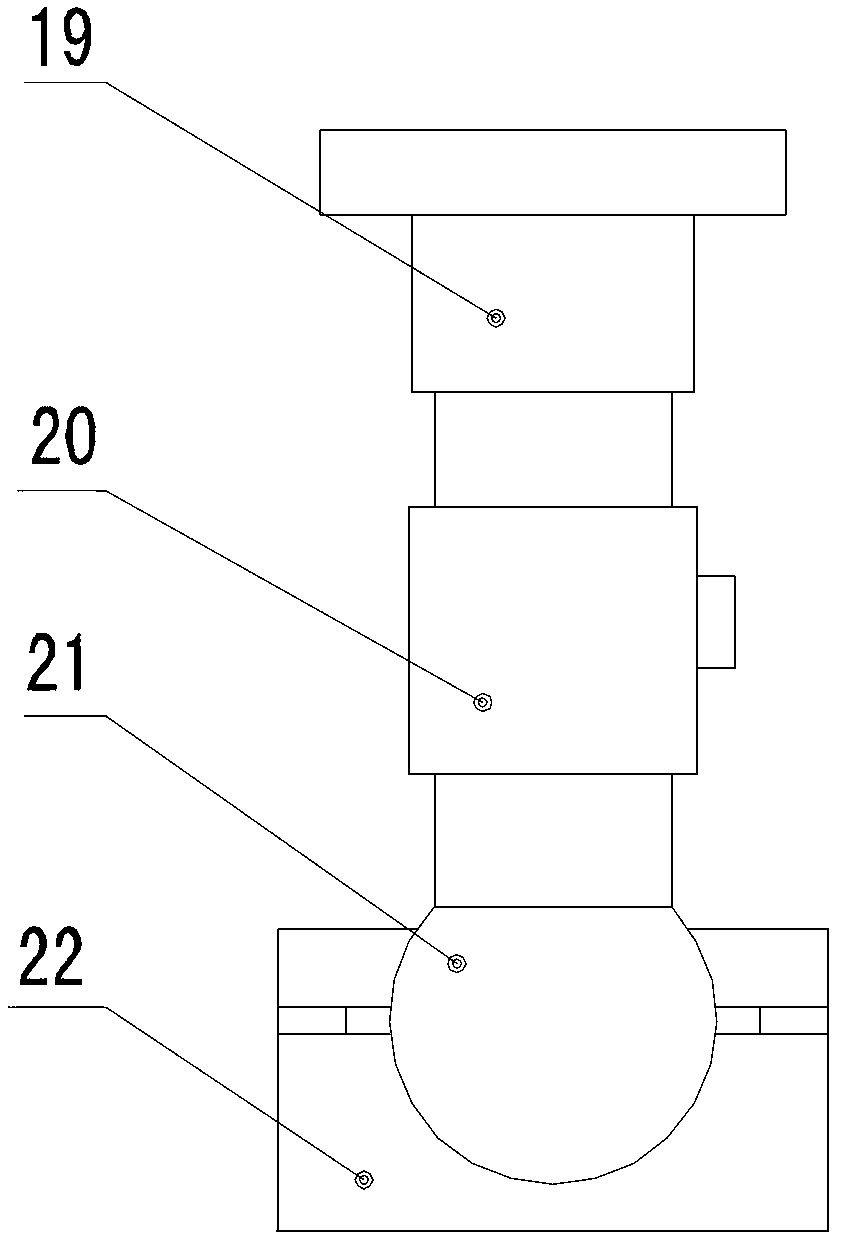

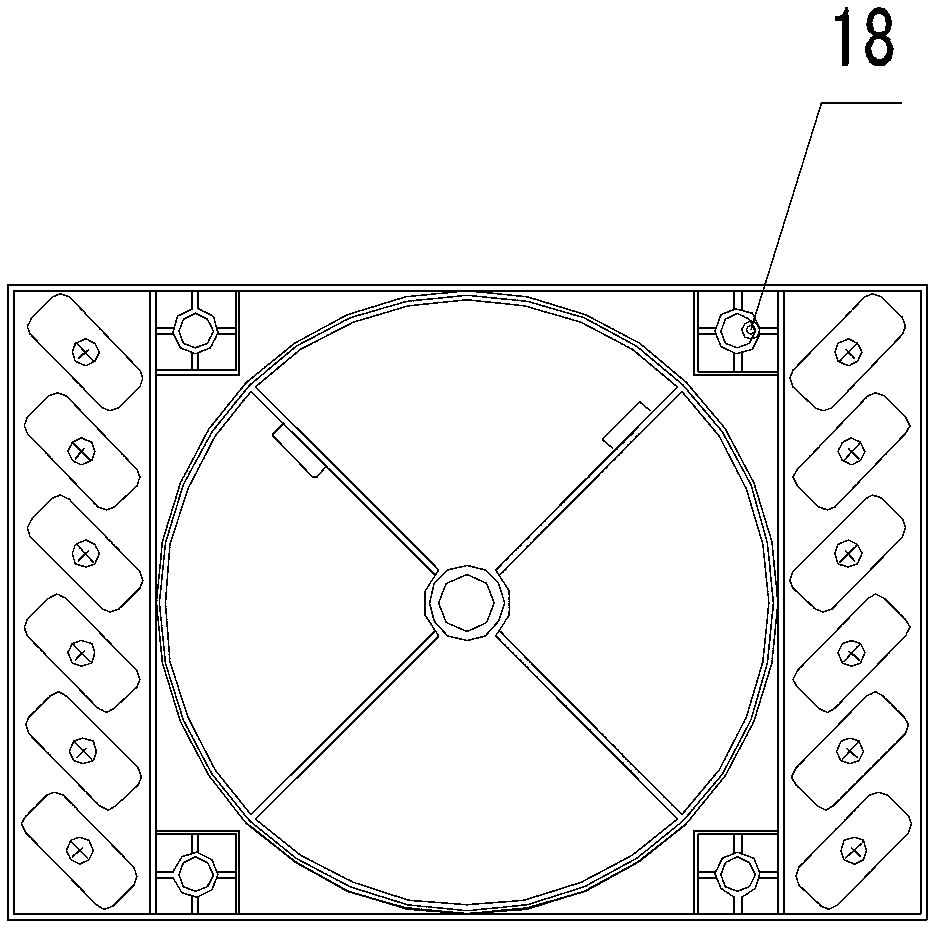

[0020] see figure 1 —6. The wine cellar entry device includes a translation mechanism 17, a lifting mechanism 16 and a working device. The working device includes a motor 1, a transmission shaft 7, a mounting plate 2, a material barrel 6, a material barrel motor 14, and a lower discharge door 10. Discharge upper door 11, base 8, cellar step mechanism 9; motor 1 is fixed on the mounting plate 2, the upper end of transmission shaft 7 is connected with motor 1, and the lower end is connected with discharging lower door 10 and discharging upper door 11; mounting plate 2 is equipped with Roller 3, material bucket motor 14; Material bucket 6 is suspended on the roller 3 through bull gear 4; Bull gear 4 meshes with pinion 13, and pinion 13 is connected with bucket motor 14; Base 8 is fixedly connected with bucket 6, step on The cellar mechanism 9 is installed on the base 8; a spreader 18 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com