tmd device with eddy current damper

An eddy current damper and damper technology, applied in building types, buildings, building components, etc., can solve the problems of low frequency adjustment accuracy, complex TMD overall structure, and troublesome installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

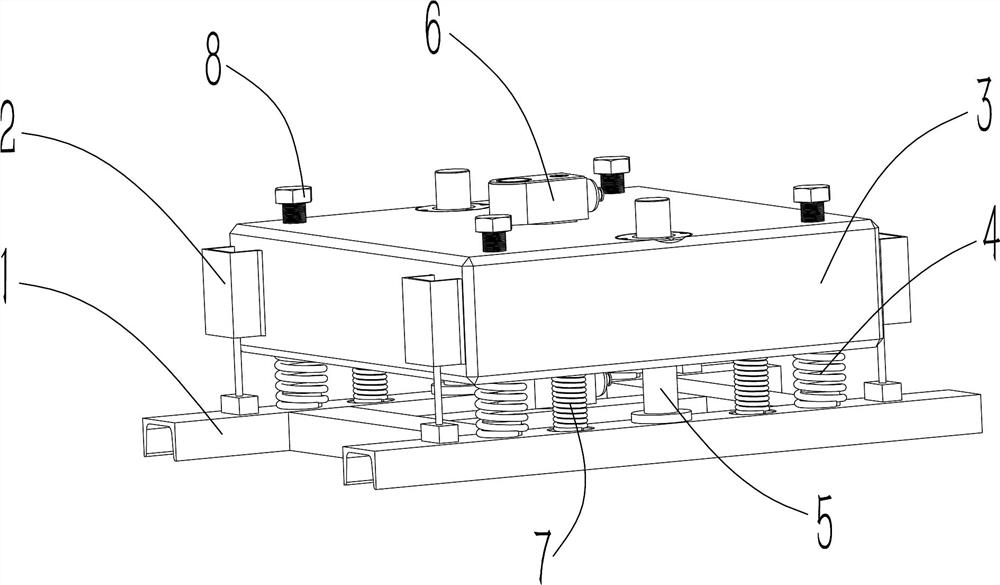

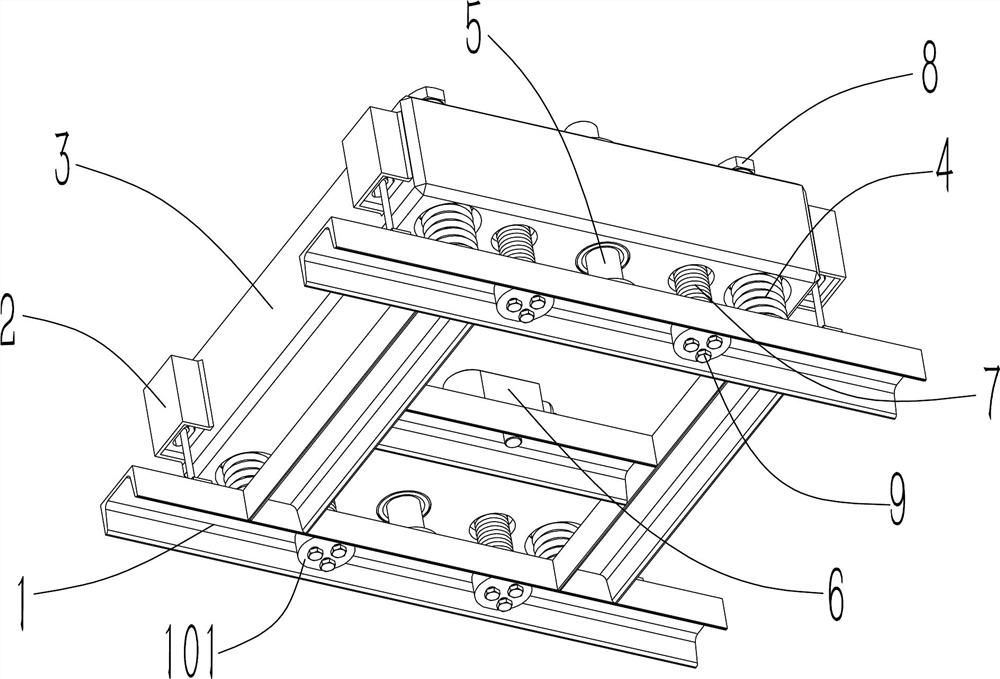

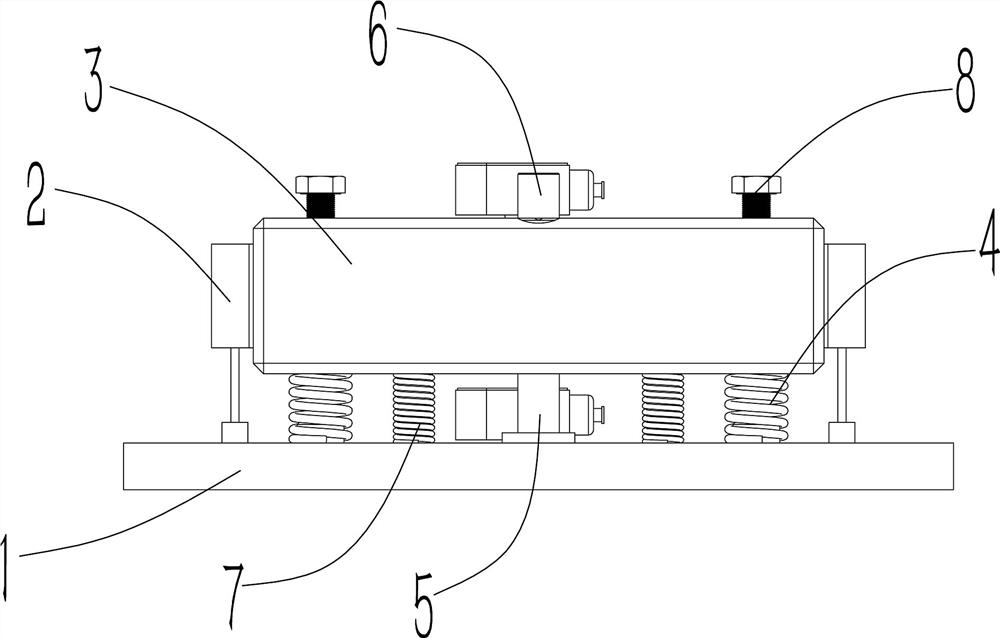

[0033] Such as Figure 1~7 As shown, the TMD device with an eddy current damper includes a support frame 1 fixed under the floor 14, a mass block 3 is provided on the support frame 1, and an adjustment mechanism is provided between the support frame 1 and the mass block 3, so that The height of the center of mass is changed under the action of the adjustment mechanism of the mass block 3, and a plurality of dampers 2 are arranged between the mass block 3 and the support frame 1, so that the mass block 3 vibrates vertically under the influence of the damper 2, and the mass block 3 and the The supporting frame 1 is provided with sensors 6, and the sensor 6 detects the vibration amplitude and frequency of the mass block 3 and the supporting frame 1. With this structure, the TMD device is fixed below the building floor 14 through the supporting frame 1, and the supporting frame 1 The two ends are connected to the beam 15 of the floor 14 by welding or bolting, and the adjustment me...

Embodiment 2

[0047] Such as Figure 8~11 As shown, a TMD device with an eddy current damper, Figure 8 is the graph of the vibration before the TMD device is installed, Figure 9 It is a comparison diagram between the vibration frequency of the floor 14 and the vibration frequency of the TMD device. In the figure, the vibration of the TMD device has a certain time lag due to inertia, so there is a certain time difference with the vibration of the floor 14. At the same time, the vibration amplitude direction of the TMD device is the same as that of the floor 14. The opposite vibration amplitude and direction cancel each other out, so as to suppress the vibration effect. By observing Figure 9 In the comparison diagram of vibration frequency, the function adjustment mechanism adjusts the frequency of the TMD device, so that the TMD device can achieve a better vibration reduction effect. Figure 10 For the vibration curve diagram of the floor 14 after installing the TMD device vibration dam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com