A hybrid rotary steerable drilling system that is easy to build up deflection

A rotary steerable drilling and hybrid technology, which is applied in directional drilling, drilling equipment, drilling pipes, etc., can solve the problem that the wellbore trajectory is not easy to control, achieve large engineering significance and practical value, reduce wear and reduce the overall pressure loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

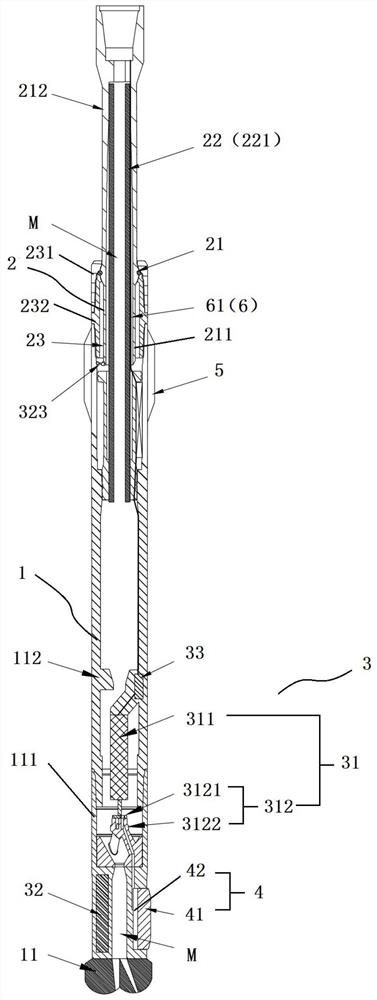

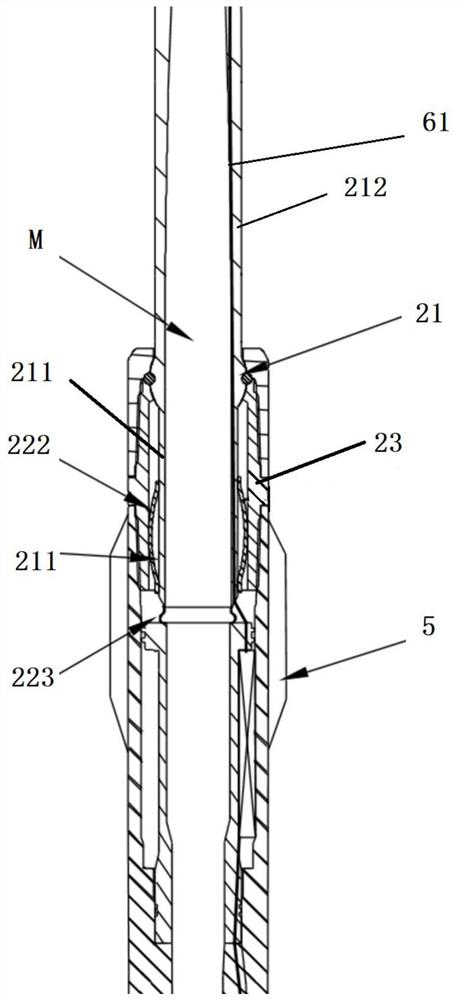

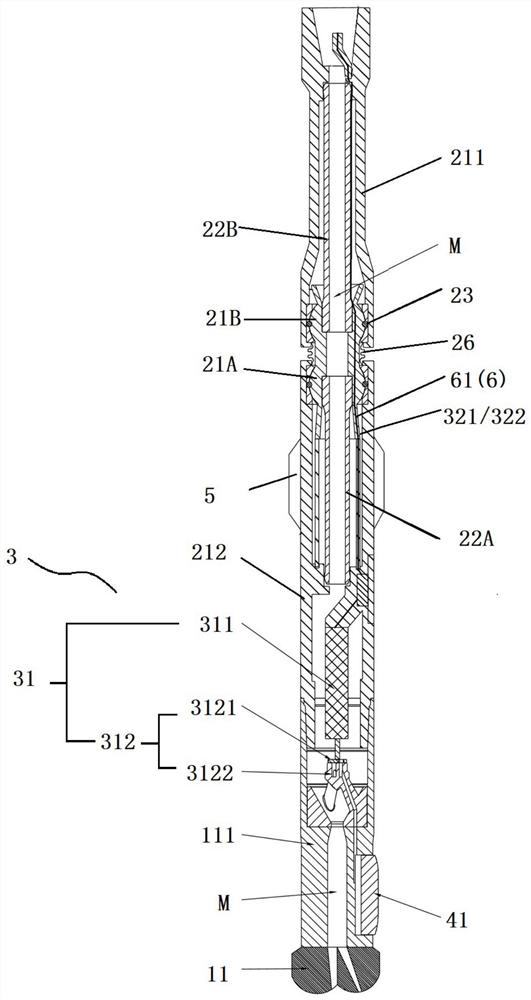

[0062] A hybrid rotary steerable drilling system that is easy to build deflection, firstly take the dynamic offset rotary steerable as an example, as shown in figure 1 As shown, it includes a front bearing body 1, a weight-on-bit torque deflection transmission joint 2 and a deflection control system 3. The weight-on-bit torque deflection transmission joint 2 includes a universal joint 21 and the input shaft and output shaft of the universal joint 21 The elastic stabilizing device 22 whose axis is on the same straight line, the front end of the front bearing body 1 is fixedly connected with the drill bit 11 , and the drill bit 11 can be integrally formed with the front bearing body 1 . The rear end of the front bearing body 1 is fixedly connected to the output end 211 of the universal joint 21 , of course, the front bearing body 1 can also be integrally formed with the output shaft 211 of the universal joint 21 . The input shaft 212 of the universal joint 21 can be directly fix...

Embodiment 2

[0066] The difference from the above-mentioned embodiment is that, if Figure 1-4 As shown, the easy-to-build hybrid rotary steerable drilling system of the present invention also includes a centralizer 5 arranged behind the front pushing assembly 1 , and the centralizer 5 is used to increase the stability of build-up.

[0067] The centralizer 5 is preferably arranged between the center point of the front thrust assembly 1 and the universal joint 21 , and the deflection control system 3 controls the radial thrust of the front thrust assembly 4 The member 41 pushes against the well wall along the radial direction of the front bearing body 1, so that the front bearing body 1 is centered on the center point of the universal joint 21 and the contact between the centralizer 5 and the well wall The point is the fulcrum, and the deflection angle is generated relative to the input shaft 212 of the universal joint 21. At this time, the contact point from the drill bit to the centralize...

Embodiment 3

[0075] Different from the above-mentioned embodiments, the deflection control system 3 includes an electric actuator 31 for controlling the radial pushing member 41 to generate a deflection force against the well wall of the front bearing body 1 , for Attitude measurement equipment 32 and downhole computing equipment 33 for measuring the gimbal deflection angle;

[0076] The downhole computing device 33 includes a computing chip electrically connected to the attitude measuring device 32, the electrical execution device 31 and the power supply device 6, and the computing chip receives the deflection angle information and target deflection information collected by the attitude measuring device 32. Comparing the angle information to calculate the steering direction and steering force, and then controlling the electric actuator 31 to make the front pushing assembly 4 produce a thrust resultant force opposite to the steering direction on the well wall, and the weight-on-bit torque i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com