Construction method for passing through muddy loose tunnel collapse body

A construction method and technology for a collapsed body, which are applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of high construction cost, short construction distance and long construction period, so as to reduce construction costs, reduce project costs, and improve The effect of construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

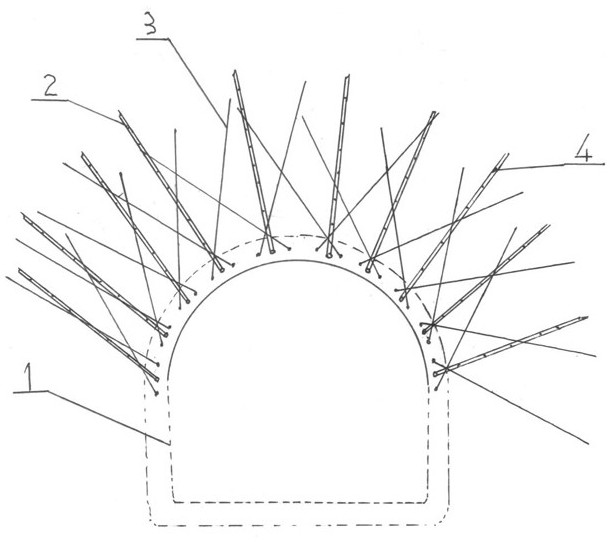

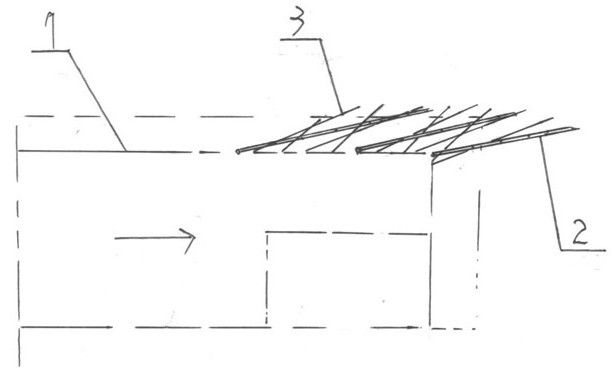

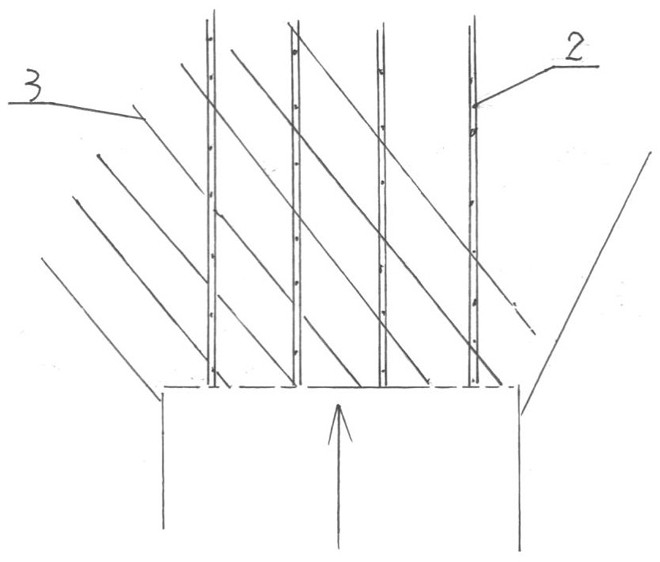

[0030] Such as Figure 1 to Figure 5 As shown, a construction method for passing through muddy loose tunnel collapse body includes the following steps:

[0031] (1) Drive obliquely forward along the tunnel excavation contour 1 a plurality of reinforcing bars 3 distributed at intervals to form a reinforced mesh shed. 4cm threaded steel bar, the length of each steel bar is 7-8m. The driving of steel bars can be rammed with an existing vibrating hammer, or jacked by cutting soil, or drilled by drilling rigs. This is a traditional driving machine, so it will not be repeated here.

[0032] The steel bars that make up the reinforced mesh shed are distributed within the range of no more than 10cm in circumferential width, the distance between two adjacent steel bars driven in is 20-40cm, and the angle between each steel bar and the longitudinal vertical plane of the tunnel is 40°-60° , the elevation angle of each steel bar is 6-8°. Two adjacent steel bars are arranged parallel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com