Aluminum alloy cable for new energy automobile and production process

A new energy vehicle and production process technology, applied in the direction of insulated cables, metal/alloy conductors, cable/conductor manufacturing, etc., can solve the problems of high cost of copper core conductors, poor shielding effect, and frequent production cycles, so as to avoid weaving And wrapping, better shielding effect, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

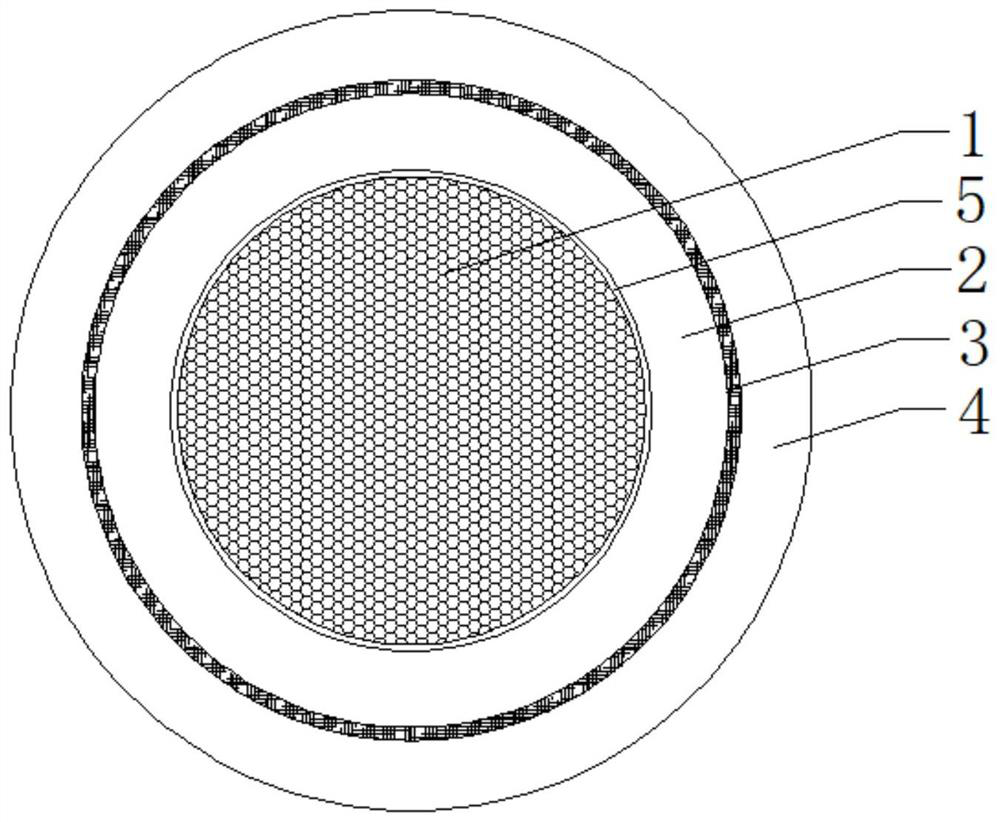

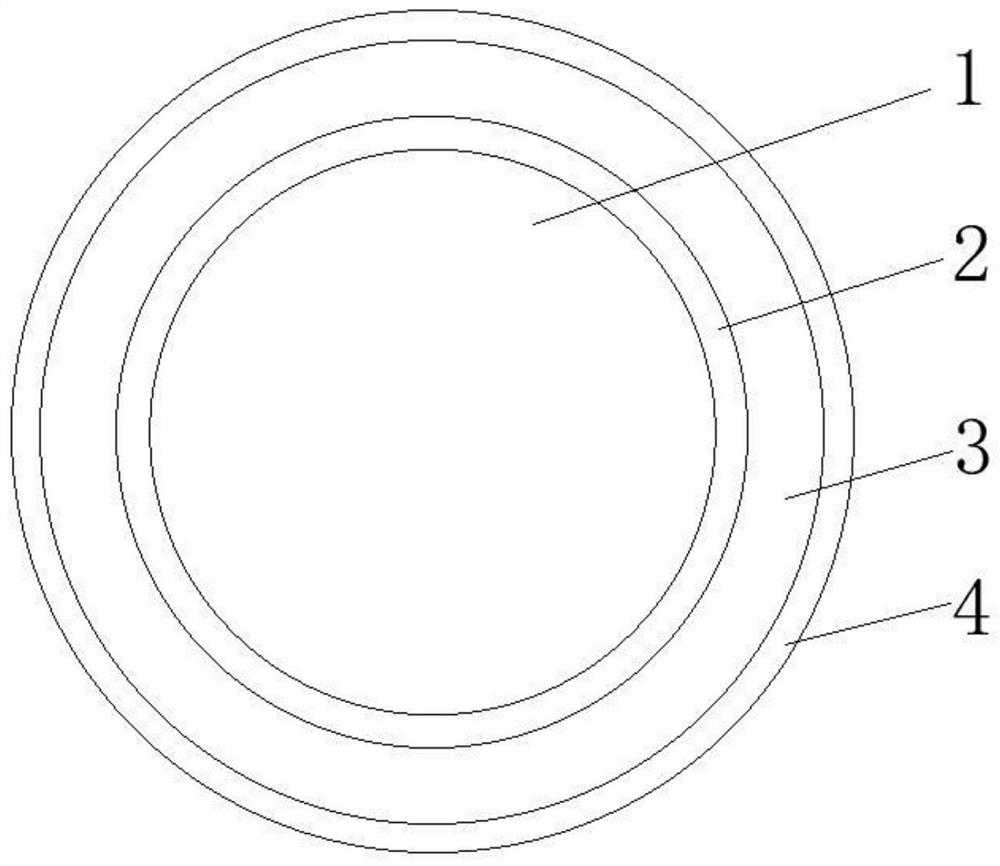

[0038] See figure 1 , The aluminum alloy cable for new energy vehicles of Example 1 includes a conductor 1, an insulating layer 2, a shielding layer 3 and a sheath layer 4 arranged in sequence from the inside to the outside.

[0039] Conductor 1 is a solid aluminum alloy conductor with a cross-sectional area of 1.5mm 2 , can greatly reduce crimping or welding defects when the stranded conductor 1 is connected to the terminal. The solid aluminum alloy conductor adopts a high temperature resistant aluminum alloy formula system, and the composition and ratio are calculated in parts by mass: Al96.5%, Mn0.6%, Cu0.2%, Fe0.6%, Si0.6%, Mg1.5 %. Its elongation at break and heat resistance are excellent, and it can operate at 150°C for a long time without deformation and has high breaking strength.

[0040] The shielding layer 3 is an aluminum pipe shielding layer.

[0041] Both the insulating layer 2 and the sheath layer 4 are solid-solution materials of PTFE and rubber, and both...

Embodiment 2

[0049] The structure of the aluminum alloy cable for new energy vehicles in Example 2 is similar to that of Example 1, the difference is that:

[0050] The cross-sectional area of conductor 1 is 60mm 2 . The solid aluminum alloy conductor adopts a high-temperature-resistant aluminum alloy formula system, and the composition and proportion are: Al97.5%, Mn0.35%, Cu0.15%, Fe0.5%, Si0.5%, Mg1%.

[0051] The shielding layer 3 is an aluminum pipe shielding layer.

[0052] Both the insulating layer 2 and the sheath layer 4 are solid-solution materials of PTFE and rubber, and both have a thickness of 1.0mm. The composition and ratio of PTFE and rubber solid solution materials are: PTFE 0.5%, EPDM rubber 40%, talcum powder 43.5%, microcrystalline wax 5%, liquid paraffin 2%, antioxidant RD 1.5 %, curing agent DCP 3.5%, curing accelerator TAIC 4%.

[0053] The production process of the aluminum alloy cable for new energy vehicles of embodiment 2 comprises the following steps:

[...

Embodiment 3

[0060] The structure of the aluminum alloy cable for new energy vehicles in Example 3 is similar to that of Example 1, the difference is that:

[0061] The cross-sectional area of conductor 1 is 120mm 2 . The solid aluminum alloy conductor adopts the formula system of high temperature resistant aluminum alloy, and the composition and ratio are calculated in parts by mass: Al98.5%, Mn0.2%, Cu0.05%, Fe0.45%, Si0.3%, Mg0.5 %.

[0062] The shielding layer 3 is an aluminum tube shielding layer.

[0063] Both the insulating layer 2 and the sheath layer 4 are solid-solution materials of PTFE and rubber, and both have a thickness of 2.0mm. The composition and ratio of PTFE and rubber solid solution materials, PTFE0.7%, EPDM rubber 44%, talcum powder 40%, microcrystalline wax 5.8%, liquid paraffin 1%, antioxidant RD 2.5%, curing agent DCP 3%, curing accelerator TAIC 3%.

[0064] The production process of the aluminum alloy cable for new energy vehicles of embodiment 3 comprises ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com